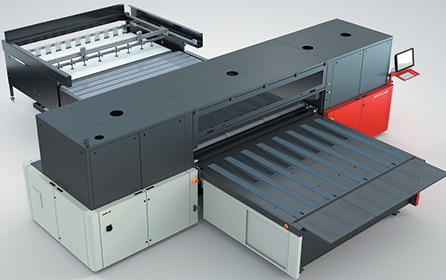

The Jeti Tauro H3300 LED is almost 8.5m long, 2.5m high and over 2.5m wide

Agfa unleashes beast with Tauro

When inspecting printed material, we normally use a magnifying glass transfixed on the smallest of dots or colours that have been laid down on the substrate, when combined make up the image we intend to make an impact with.

Whilst this attention to detail is vitally important, there are times when the completed product needs to be viewed from metres and metres away and the image size needs to be vast. There are only a small number of printers that can step up to the plate and deliver this pin point accuracy on these large square meterage products.

The product under scrutiny this month is one that can do this and in vast volumes; it is the Agfa Jeti Tauro H3300 LED. This is a hybrid inkjet printer with LED instant cool drying to make the sheets scuff proof and ready for dispatch directly from the printer.

The size of the Tauro 3300 is the first thing that impresses even the most causal onlooker. It is nearly 8.5m long and over 2.5m wide and 2.5m high. At the heart of the printer is the print head shuttle that carries the 60 inkjet nozzle, piezo electric Rioch 5420 print module. It has to be of rigid welded construction as it needs to span the 3.4m substrate width with the minimum of sag or distortion.

The size of the Tauro 3300 is the first thing that impresses even the most causal onlooker, it is nearly 8.5m long and over 2.5m wide and 2.5m high”

Any changes in height between the width of the material will bring about changes in colour. These may be small in nature, but the overall effect will be seen in colour changes when viewed from a distance. To ensure the large span of colours are accurately deposited, the printer head moves along recirculating ball linear bearings. An encoder strip ensures the Rioch head is placed exactly where needed and there are linear motors and dampeners to move the head smoothly and quickly.

Along with robust design the print shuttle also carries an antistatic bar to minimise the build-up of static electricity that tends to build up when printing on plastics and safety sensors that can be easily adjusted or maintained.

Agfa’s latest challenger can print on a more extensive selection of substrates

With regards to the print head itself, it uses UV inks fired from a 60, seven pico-litre nozzles with 48 of them used for the CMYK colours along with light cyan and black. To help with extending the range of materials the Tauro 3300 can print on, you can also lay down a primer to help with adherence and white to add vibrancy. Gloss and satin modes are also available which enhances spot colour production without any loss of image quality.

The inks themselves are of a patented design and Agfa refer to them as ‘Thin Ink Layer’ technology. This means the inks are highly pigmentated which allows them to be laid down thinly without using excessive amounts of ink.

The final part of the wide gamut of colour available on the Tauro 3300 is the algorithms used in the Asanti workflow software used. Agfa claim the combination of Thin Ink Layer and software mean the Tauro 3300 has the lowest ink consumption of any printer on the market.

The final part of the vibrant colour output is the drying system, LED UV curing. Over the last few years, this technology has now firmly established itself as the benchmark standard. It provides instant touch dry products but most importantly is cool and as a result, heat sensitive materials can be easily printed.

The lamps can be turned on and off on demand due to the size of the substrate being used. The nature of the technology means they do not need to heat up or switching them on does not affect their lifespan, which can be expected to be in the region of 10,000 hours.

The lamps do not contain Mercury and due to the low energy consumption and long life span, it all makes for a very efficient, cost effective drying system. Finally, the system running as cool as it does, needs no ventilation nor does it produce Ozone which makes the Tauro 3300 very comfortable for the operator to use.

The lamps do not contain Mercury and due to the low energy consumption and long life span, it all makes for a very efficient, cost effective drying system ”

Colour laid down on playing field sizes brings about a number of issues, the most pressing being the transport of the substrate itself. Agfa have invested as much in the solution to this problem as they have in the print head shuttle.

You can have the machine in a number of configurations but there are four main models. The most basic model is the manual loading, unloading version which requires the operator to load the board or sheets by hand. This by no means reduces the output of the printer which can be as high as 453m2/hr. If your production needs are mainly one off or small number batches, this version will be the correct balance of investment.

The lamps used for the LED UV curing system contain no Mercury, with low energy consumption and have a life span of around 10, 000 hours

Second in the stable is the semi-automated version available and, in this case, you still load the substrate by hand, but the printed material is stacked automatically on a scissor lift pallet handler. Both these versions can be turned into the third version, the master roll-to-roll configuration.

As the name suggests, this version does not require any form of manual intervention as the substrate is thinner and unwound, printed and rewound onto reels. The maximum reel diameter is 600mm and must not exceed 800kg in weight. This version can produce dual reels of 1.6m in width but the combined weight can be 1,600kg in total.

The final model is the fully automated version. As this description outlines, both the loading and unloading of the sheets is down via a cleverly designed pick and place mechanism. To ensure the sheets and boards are placed correctly on the vacuum table, the Asanti workflow software raises and lowers the correct register pins depending on board size.

Speaking of the Asanti software, the graphic user interface (GUI) allows you to operate the whole process of printing on the board or sheet. You can draw down the images, lay them efficiently on the table and queue them up for seamless production.

Whilst the size of the Tauro 3300 is impressive in itself, much like the printed material it produces from both afar and very close up, you can see the printer is an extremely well designed and able machine.

Brian Sims Principal Consultant, Metis Print Consultancy, www.metis-uk.eu

Your text here...