(Above) The EFI H1625-SD provides the market with a technology solution that expands the creative scope of wide-format printing through its unique ink technology

When computer controlled machinery first started to take our industry by storm, it simply took what was once a manual process and automated it. It made something that was subject to variables, controllable and repeatable, time after time with no visible differences.

Equipment such as vinyl letter cutting equipment then CNC routers did not replace the old skills at the time, as you were still needed to be able to lay out a job beforehand to create a pleasing finish.

As times have moved on, so the software became more powerful, but to some extent it is possible to operate a small scale sign shop without those design skills and be moderately successful at it.

As times have moved on, so the software became more powerful”

Digital technology has opened up our trade to anyone with the means and determination to have a go, and more importantly be consistent. With the right kit list you could do a job this morning and that same customer could come back in a couple of years and you could do it all over again exactly the same.

Certain processes though remain the preserve of specialist trade houses or bigger companies with volume orders. One such process is vacuum forming. The kit is, in theory, expensive and some element of hand finishing would be required to be truly creative—such as air brushing or spraying to recreate the finished article.

It is a process that might seem a bit dated now, but there is still plenty of high street brands using a vacuum formed logo or text as part of their brand, along with many point-of-sale items. I for one always thought that it was not something that was worth considering though, as the volumes did not quite justify looking at it as an investment option.

EFI, which has a large US customer base, has come up with something that brings this fairly traditional process bang up to date and does really what technology should do. Taking a traditional process and applying technology effectively simplifies it, makes it consistent, and more importantly, cost-effective.

If you build it…

With the market for traditional engineered signage still strong in the USA, the sales potential of a printer that is capable of printing directly to plastics, that can then be vacuum formed was large. Add in EFI’s global presence and ink technology, and the resulting product has huge potential.

I have looked before at printers capable of printing directly to a wide range of rigid substrates and, to be honest, the choice of which machine to go for is as much about brand loyalty as anything else—they all do a great job.

Conventionally these machines are sold on the ability to print directly to a range of substrates at a fraction of the cost of printing onto vinyl and then applying that print to a panel.

The margins for this work have reduced as the years have gone by, but it is still a viable opportunity if you have the work. Some manufacturers are now starting to demonstrate to potential buyers how creative you can be too. UV ink is coming on in big leaps, and now the latest versions of ink and machines are starting to see increased elongation properties, without the environmental and handling issues of solvent-based ink.

The margins for this work have reduced ”

EFI have a long reputation for supplying high volume super-wide printers with class leading inks and RIP software. But the entry-level option of the EFI H1625-SD offers a unique proposition too, and add the addition of a vacuum former from someone such as Formech, and you could have yourself a completely different creative process to offer your clients.

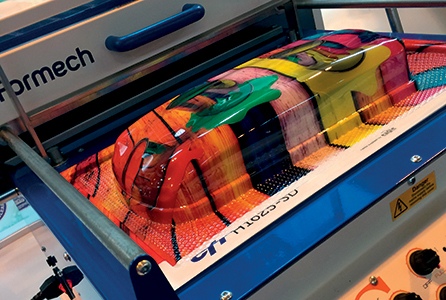

A printed mock-up that was produced using the EFI H1625-SD and Formech 300

Formech offers a range of formers, the bestselling of which is the 300xq—which has a capacity of 450 x 300mm and comes in at about £2,500. As you would expect, sizes and prices get bigger from there depending on what your requirements are and how your business grows. This means prices run all the way up to a £90,000 system capable of producing work 2,400 x 1,200mm. Whilst there are other things to consider such as the formers, it something that could prove quite an exciting addition to a sign-maker’s arsenal when pitching for that job that needs something a bit different.

The Formech 300 is the entry-level point in this company’s range, but allows you to diversify into providing vacuum formed promotional items at an affordable price tag

When EFI launched the H1625-SD, its initial potential was not fully recognised, as it was demonstrated on the basis that ink forms a very strong bond with the substrate. So difficult materials such as extruded acrylic and jobs that could be subjected to light damage are not an issue with this ink, such is its durability.

It is costlier than the ink used in the standard H1625-LED, but the SD ink allows potential users to print onto substrates with higher than usual resistance to fade, and also materials that were difficult to get ink to bond to.

EFI also offers machines that carry the same DNA as this entry-level system that go all the way up to 3.2m wide in the form of the GS3250 Pro-TF. The range of printers and their applications in the EFI stable is vast, and so it is probably no surprise that large numbers of companies involved with super-wide format printing will probably have an EFI Vutek printer in their armoury. What is important about the H1625-SD is that it brings this company’s technology within the reach of smaller companies.

The system’s modular design is also clever, as its different ink set options and upgrade features means it is a versatile beast that can adapt to the demands of the company that uses it. To my mind, the SD option tied to a vacuum forming device could really give you a unique edge over your competition, broaden the contracts you can pitch for, or expand the products and services you can offer to your existing customer base.

Allen Signs is an established family run business with over 100 years of combined experience. It provides a complete sign, display and vehicle livery solution from concept and design through to final installation and maintenance.

For more information on the issues discussed in this article please visit www.allen-signs.co.uk or tel: 0115 704 3017

Your text here...