Keith Piggott has been managing director of Perspex Distribution since its creation in 2003

What is your history in the sign and display industry?

I have been involved in UK sign and display since founding Amari Plastics in 1975, within the Amari Group, and was managing director of the company for 26 years.

Since its creation in 2003, I have been managing director of Perspex Distribution Limited (PDL). PDL is wholly owned by Lucite International (LI), the manufacturers of Perspex Cast Acrylic. I met with the directors of LI to discuss possible solutions that would improve the Perspex brand sales performance in the UK market using their manufacturing capability and resources together with my knowledge of the market. A decision was reached to form a distribution company—this was an entirely new venture into distribution for LI. PDL have not looked back since and we have grown from a single site operation based in Chelmsford to recently opening our fifth distribution site in Leeds earlier this year.

Perspex Distribution opened a new Leeds branch, housing its largest levels of stock for local distribution

As well as continuing the successful growth of PDL, I was also appointed general manager of the LI EMEA sheet and composites production business based at Blackburn, Lancashire, in 2014. This role evolution has further united the production and research and development of Perspex acrylic with the PDL distribution arm, which has improved the way in which we respond to demands in the market and the speed of our new product development.

I have also served as president of European Plastics Distributors Association and director of the International Association of Plastics Distribution.

How has Perspex Distribution grown over the last few years?

We have continued to experience strong demand over recent years, however the climate has been challenging and we have seen established competitors disappear as well as new distributors emerge.

We need to demonstrate every day to our customers that we can provide products and a level of service, knowledge, and information that will be of benefit to their business and convince them that their best distribution partner is PDL.

To remain successful in this market, our focus on excellent products from the best suppliers is paramount. We are proud of the heritage and sustained quality of our Perspex acrylic that has continued to be manufactured in the same Lancashire factory since 1934. We have built strong relationships with other successful UK sheet manufacturers such as Multipanel, the UK’s only producers of aluminium composite panels, and Palram who extrude our PVC foam and polycarbonate in Durham and Doncaster.

From the outset, we have been dedicated to our expertise and knowledge of sheet thermoplastics. We have seen traditional sign-makers grow their businesses by diversifying into print, point-of-sale, and illumination, and we too have increased our product offering to be better equipped to take advantage of growth in various markets.

We have seen traditional sign-makers grow their businesses by diversifying into print, point-of-sale, and illumination”

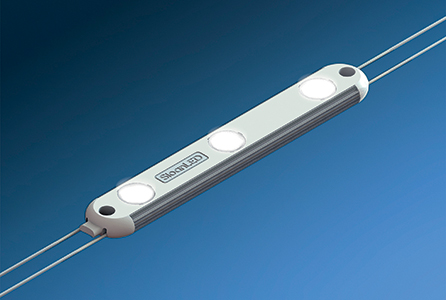

We entered the signage LED market in 2013 and have been enthused by the inroads we have made to date alongside module suppliers SloanLED. We invested in a new LED product management team who have driven sales growth via direct relationships and through training all our branches to handle LED enquiries, once again demonstrating our focus on superior products and the service offering to our customers.

This strong demand across all product groups in the UK has required us to recently expand our business by opening our fifth and largest branch in Leeds.

What new products are Perspex Distribution excited about currently?

In the last four months, we have launched four new ranges in the commercial lighting and display industries with great success: Perspex Edge, Perspex Diffuse, Perspex Reflect, and Perspex G-Lux. These particulate-filled technologies give opportunities for more creative designs, offering bright, slimmer lighting units that weigh and cost less, without the need for additional fabrication costs required in other light guide panel technologies, a much more compelling proposition all round.

A great example where our LI product development is keeping pace with the rapid evolution within LED lighting technology thus creating new opportunities for further growth into new markets.

We are also in the middle of a technology breakthrough with our SloanLED modules and are genuinely excited about the unique products coming to market. We recently launched SloanLED Prism with a unique micro-prism lens providing sign-makers with versatile modules for brighter lightboxes and channel letters. We have also had great customer feedback on a new module for large flex-faced lightboxes—Poster Box 3—enabling over three meters of illumination.

Perspex Distribution has had “great customer feedback” on a new module for large flex-faced lightboxes from SloanLED called Poster Box 3

How have Perspex Distribution’s products helped brands come to life?

As always, the applications for our products are almost endless. It is no exaggeration to say that we see our products everywhere from printed graphics on our Alupanel aluminium composite panels advertising brands in Premier League stadiums to Palight PVC foam used by set builders for the latest TV gameshow.

You will see from the case studies on our website that our fabricators use Perspex acrylic in some amazing projects. Recent examples include a Saint Laurent shoe promotion at Selfridges, Perspex Clear being fabricated in London and shipped to the Burning Man arts festival in the Nevada Desert, and the gold medal winning Team GB Hockey team celebrating their win using Perspex acrylic selfie sticks.

You had an increase in leads at Sign and Digital UK. How did this benefit the company?

Trade shows such as Sign and Digital UK provide a great opportunity to reinforce our message to the marketplace and it is always great to see new visitors.

Sign and Digital UK has increasingly focused its attention on wide-format print. This year we worked closely with printer manufacturers such as Agfa Graphics and Canon to bring our materials to life, and demonstrate the performance of our innovative substrates such as Alupanel A-Lite digital and Palfoam anti-static digital to a live audience. This helped position PDL as a key supplier for printers seeking well tested substrates. These relationships have continued through the year and we recently attended Agfa’s ‘Eyes Wide Open’ three-day event, helping us maintain a high profile alongside industry leading print suppliers.

What impact has the opening of a fifth branch, in Leeds, had on Perspex Distribution?

Our expansion is a direct result of our need to meet customer demand across the region. Opening our largest distribution operation in Leeds provides us with a strong foundation to grow both our product range and customer base in the years to come.

We specified the site design, which has enabled us to house our largest levels of stock for local distribution as well as establishing a purpose-built storage and distribution area for smaller products such as LEDs, which are centrally despatched throughout the UK.

We have also generated 22 new jobs within the site in a range of roles from sales, administration, warehouse, and drivers.

What can we expect from Perspex Distribution in the future?

The fast-moving pace of the lighting market excites us and we will continue to probe growth via the ongoing development of specialist Perspex acrylic substrates that work hand in hand with our LED modules.

We continue to raise awareness of our non-Perspex acrylic ranges and see further opportunities in the wide-format print markets with our PVC Foam and aluminium composite. Our current five branches are working well today, but we see the need to expand further in order for us to continue to meet UK national demand in the future.

Our customers are approaching the future with confidence and we look forward to growing with them”

Our customers are approaching the future with confidence and we look forward to growing with them.

Key Stats

- Founded Amari Plastics in 1975

- Managing director of

- Perspex since 2003

- Acrylic manufactured in same factory since 1934

- 22 news jobs generated from Leeds branch

For the full interview go to www.signlink.co.uk and search ‘Piggott’

Your text here...