HNS Signs’ Michelle Henry swears by her Yellow Tools sign-making case, because she says it is only really worth having the right equipment as long as you know exactly where it is

As the leftover turkey and sprouts are all eaten up, and the Yuletide tinsel is stuffed back into the attic for another year, we all have plenty of time to consider what New Year’s resolutions we will make. Like Bridget Jones opening a new diary and promising to better ourselves as the year opens, January affords us all that opportunity to start afresh with a clean slate and to simply ‘do better’.

On the other hand, it has become more than a cliché to suggest that our new diet, exercise regime or work ethic will merely last until we get back to the grindstone and power through the first stressful day of the year—normally day one, if we are honest. More often than not, our resolutions will be as hastily dropped as they were made; the takeaway boxes pile up, the new ‘boxercise’ class goes willingly forgotten, and we slump back on our laurels, all sites of change fading with the obligatory Christmas hangover.

However, as a business, it makes little sense to start making changes for the better in the New Year and drop them by the next month that rolls around. As businesses, our resolutions range from promising to keep our books in order all the way to the end of the tax year, vowing not to let job times slip, or even resolving to make that big purchase we have been putting off ‘until the money comes in’ or ‘when that big order is over’.

Instead of concentrating on where we lack, and chasing our tail to catch up, a more positive outlook is to see it as picking up good habits and sticking with them, precisely because they make the most business sense.

So, how do we pick up these new, good habits and keep them? Well, I have often found that having the right tools around me to start off with can be a great inspiration, and that is especially true when talking about giving your production times a little slimming down.

From having spoken with sign-makers over the years, at Sign and Digital UK and FESPA, or simply talking shop to our readers about their set ups, there have been a number of tools, from the smallest hand-held gadgets, to huge contraptions made of acres of steel and cables, that sign-makers claim has made their working lives easier and faster-paced, and which have proved so useful that their old bad habits have been thrown out without a backwards glance.

As well as diving into some of the key pieces of time-saving tools out there, sign-makers have spared some time to tell us about their top time-saving sign-making tools, and what good habits their businesses have picked up as a result.

Cutting some slack

One such company is Baillie Signs. Based in Edinburgh, the firm manufactures and supplies all kinds of signage throughout Scotland, from the smallest plaques and A-boards, to grand-format fascias and bespoke cut lettering, such as the recent commission of Edinburgh Airport’s new entrance sign, which is so big a person can stand inside the letter ‘I’.

For projects of this scale, a hefty piece of equipment is required. Paul Lennie, sales manager of Baillie Signs, explains that this is why the firm made a recent purchase to help it cut down production time across the board.

“We have recently invested a six figure sum in the purchase of a Zund Digital Cutter that allows us to handle sheets up to 1.5m wide,” Lennie explains, adding: “This enables us to cut down on manual cutting of materials and strengthens our ability to manufacture many items such as sign trays and flat cut lettering from a variety of materials—including but not limited to foamex, dibond, acrylic and woods—much more efficiently than ever before.”

Not only has the firm found that the new digital cutter has significantly sped up their production rate, it has also come with its own tools to widen the company’s offerings. Lennie continues: “This purchase has optimised our workflow and allowed us to seek out new business in areas where we weren't as competitive as before. With its variety of tools and cutting blades, we can router sign trays, polish acrylic edges and even form our own cardboard boxes.”

This purchase has optimised our workflow and allowed us to seek out new business in areas where we weren’t as competitive as before”

While a top end digital cutter might be every sign-maker’s dream, not everybody has the room, or budget, for a flatbed and often set up time and training for this equipment can be a hurdle for the smaller firm. However, though it is perhaps not the best looking piece of equipment in the world, a vertical substrate cutter is quite a brilliant time-saver for the modern sign-maker, especially for those low on space.

These pieces of equipment are designed to be flexible, accurate, and fast. A number of companies manufacture an A-frame style vertical substrate cutter, at different heights, and even, in some cases, extendible, to factor in the varying lot of a sign-maker’s day-to-day work. Crucially, they can also cut a wide range of substrates, from corrugated plastic and foam board, to aluminium panels and mdf—basically the whole of a sign-maker's arsenal.

The Yellotools team travels Europe on its special bus showcasing the huge array of specialised sign-making tools that not only save time, but increase the quality of the finished product

Many of these, such as Keencut’s SteelTrack, are also designed to be quiet and dust free, which certainly saves time on keeping the workshop clean and having to repeat yourself to hard-of-hearing colleagues.

Apply some pressure

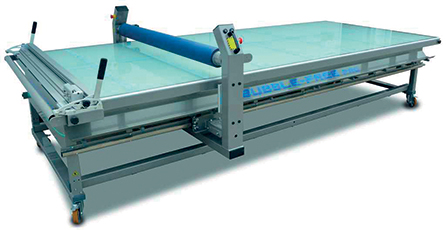

Another hefty piece of equipment that can certainly put a dent in a large-format print provider’s production time is the flatbed applicator table. Many smaller companies will often baulk at the costs of larger flatbed printers, but know in their heart of hearts that, in an increasing market for wide-format multi-substrate printing, it will eventually become a necessary tool to keep the profits rolling in.

An applicator table can not only be an excellent stop-gap for the businesses not currently able to make that investment, but also help speed up production.

Essentially a rich man’s laminating table, an application table can handle multiple substrates in the creation of media from road signs to banners by accurately pressing an adhesive-backed, roll-printed wide-format print onto virtually any substrate including foamex, dibond, and Perspex.

The manufacturers behind systems such as the Rollsroller and the Bubble Free Pro Applicator, which is distributed in the UK by Josero, have carefully listened to sign-makers in the creation of these tables, making them the most versatile tools to cut production times. They boast the ability to handle varying thicknesses of substrate, and include such features as a backlit table to make the lining up process faster and more accurate, a manual, overhead roller to allow single-handed operation—freeing up colleagues to increase job capacity—and self-healing cutting mats, so that the table can be used as a work surface when the roller is not in use. Looking specifically at the Bubble Free Pro, it also features a cutter, allowing the operator to handle a full roll of printed material alone as he can cut each sheet as he goes along to apply on boards. The Pro also uses a reverse bridge which makes the operation easier than the classic version, as you do not have a bridge in the way.

The Bubble Free Pro Applicator has a raft of features designed to improve productivity and make the operator’s life easier

“One of the most common things our customers say a week after purchase is, ‘I wish I had bought one before’,” says Loic Delor, managing director of Josero.

Indeed, one customer that invested in the Bubble Free Pro was Signs Express Bedford, with managing director Chris Hardy emailing Delor the following: “Good news. Since the installation of our Bubble Free Applicator from yourselves recently, I have been delighted each day to see the expected increase in productivity and quality of our signage panels and graphics. My Production team are smiling as they use it. Additionally, we were impressed with the installation and training by your team, please give them our thanks, and we will be recommending this to other Signs Express centres across the UK.”

That’s a wrap

While we are on the subject of vinyl, have you ever seen the competitive car wrapping competitions at FESPA or Sign and Digital and thought ‘how on earth do they manage to do that so quickly?’ Granted, not all customers really want their vehicles wrapped in the time it takes to make a cheese toastie, but it is impressive nonetheless, and lessons can be learnt from the Lewis Hamilton’s of the wrapping world.

While a lot of it will of course be dependent on technique and experience, such as preparing your materials properly, knowing where all the joins will fall on the vehicle before applying, and cleaning the surfaces carefully, there are also tools that can easily help you cut down wrapping time.

HNS Signs in Birmingham, whose bespoke signage, traditional sign writing, and creative use of materials and lighting in its outfit has been steadily garnering attention, is also in the position to offer the more and more lucrative vehicle wrapping. Michelle Henry, managing director and hands-on sign-maker, has plenty of experience and knows when a good tool can help shave vital minutes, and sometimes hours, off production time.

Henry says: “My top tool would have to be the Rollerpro Rivet tool. This item is fantastic for when you have to cover large areas of material that has rivets with vinyl. Whenever we have to wrap a Luton, this item is a godsend. How it works is that you apply the vinyl but leave an air channel running the length of the rivets. Then you heat the vinyl and roll the Rollerpro over them and its done.

HNS Signs’ Michelle Henry reserves special praise for the Rollerpro Rivet tool, which has helped the company take on jobs that require the wrapping of difficult vehicles

“We have also found that it is useful for other areas of vinyl application, like going over locks, wing mirrors and so on.”

The Rollerpro is the size of your hand, and at around £65, Henry says this tool is practically a no-brainer when it comes to vinyl application, as it turns some of the fiddliest tasks into a breeze.

Henry also adds that it is all very well to have these time-saving tools safe in the workshop, but for those who go out to work on location, sometimes the most basic tools can be crucial to a job well done. She says: “I would never be without my Yellow Tools sign-making case. It’s only a simple thing, but I love it. It makes transporting knives, squeegees, chinagraphs around site easy.

O Factoid: The very definition of a multi-tool, a traditional sign-writer's tool box is designed with a secondary purpose—as a platform to sit or stand on. Traditionally, an apprentice's first task is to make their own tool box. O

“Since discovering this, when working in Australia, I have also not had to worry about stabbing myself on a knife blade every time I have to put my hand into a tool box!”

Vehicle wrapping and vinyl application have quite a vast arsenal of tools, from as basic as gloves, to as seemingly complex as infrared thermometers. In the spirit of Henry’s hand-held helper, here are some of the small but mighty tools that wrappers swear by to cut down on time:

The squeegee: An imperative wrapper’s tool, there are a number of different shapes of the hand-held applicator available which will help you out depending on the curvature of the vehicle. A rectangle with rounded edges is good for curved surfaces, whereas a stiffer squeegee is better for flat surfaces, and a wet-apply is necessary if you use films that require liquid for vinyl application.

Essentially, it is all about having the right tool on hand for the job, so if a particularly curvaceous car is driven in by a customer wanting the latest on-trend outfit, it is good to know that your most basic tools are up to the challenge.

Snap-off blades: During the cutting and wrapping process, most sign-makers say that you will likely replace your blade three to five times. Snap-off blades make this much easier and economical without switching blades. Another reason for using snap-off blades rather than replacements is to reduce the chance of scratching the vehicle’s paint, which can be a head-ache when a return customer comes back a little miffed that their Masarati looks like it has been to a hamfisted barber.

You can also purchase blades with different angles to help when cutting either straight or curved lines. For example, a 60-degree blade cuts straight lines better than a 45-degree blade. Knowing the appropriate tools to use is half the battle when it comes to cutting production times.

Magnets: Many vinyl wrappers swear by the use of magnets if they find themselves caught short handed and need to complete a job. A simple set of magnets could be the difference between a lumpy half job and a stunning finish when your apprentice goes off sick.

Cutting tapes: Cutting tapes come in two types, wire trimming and protection tape, and are both helpful tools to speed up your wrapping. The first has a cutting filament embedded into the adhesive. When you place the vinyl over the tape, the wire filament can simply be pulled up and it will cut through vinyl without the need of a blade.

The second gives you a little more freedom with your cutting by acting as a barrier between your blade and areas that need to be trimmed, such as badges and mouldings, protecting the paint underneath.

High speed connections

In this digital day and age, a sign-maker’s tools are more than things you can hold in your hand or keep in your workshop. The canny sign-maker will know that a web presence is necessary for business, and can help cut down massively on production time and late payments, especially when most of your orders come through an e-commerce website.

Cornish wide-format print company Print 2 Media is one signage firm that has its head truly in the digital Cloud. You may remember the company as the first sign-maker to offer payment by Bitcoin on their website.

So, it was no surprise that when asked what his greatest time-saving tool was, Print 2 Media’s web development specialist Dave Dean immediately says: “Without a doubt, the thing that has helped Print 2 Media grow at the speed it has, whilst keeping its team small and nimble, is its self-built website, integrated order and process management systems and accounts system, which are also hosted web apps.”

Without a doubt, the thing that has helped Print 2 Media grow at the speed it has, whilst keeping its team small and nimble, is its self-built website”

He continues: “Customers place an order on the website and pay up-front. This order is automatically merged into our order management system via an online API. The order management system handles the lifecycle of the job from invoicing to shipping. It talks to our accounts system via another online API and automatically generates a VAT invoice which can then be reconciled against our bank feed which will contain the payment that was automatically received from the payment gateway on our website.”

Dave Dean of Print 2 Media claims that the company’s website is its biggest time-saving tool of all

Dean says that the time-saving elements of its well-designed website cover everything from hardball sales, which the website handles relatively passively, data entry, chasing payment, mistakes that may be caused by inefficient process management, accounting and tax reconciliation, which the inbuilt software covers.

Dean admits that Print 2 Media’s new DYSS X7 flatbed cutter and router has made a difference to the company’s output. He adds: “There’s no doubt it has had a large impact on how fast we can finish signs. It also means we can handle higher volume jobs without impacting production capacity.” How-ever, there is no doubt that Dean's favourite tool is the technology at his fingertips.

Print 2 Media's DYSS X7 flatbed cutter and router has made a significant difference to the company’s work turnover

It seems that everyone has their favourite time-saving tool—from a six-figure purchase, to the £60 pocket-sized ancillary.

What is without a doubt is that clever usage of these tools can help your business pick up some good habits this year, and, more importantly, stick with them.

Your text here...