One of the biggest growth areas for screen printing products is the market around ‘one-off’ designs normally sold by boutique fashion stores

Once the core sign-industry printing process, in recent years screen printing, particularly in the UK, has very much taken a back seat, with printers and sign-makers embracing digital print. Although there are still a few dedicated screen printing operations, many have retained screen printing as only a small-scale part of their offering while others have abandoned it altogether, with much of the volume work being subcontracted overseas.

However, there are certain markets where screen printing is carving a niche for itself. A report published by the worldwide authority on the pack-aging, paper and print industry supply chains, Smithers Pira—The Future of Screen and Digital Wide Format Printing to 2017, backs up anecdotal evidence of this sea-change in the screen printing industry.

In his briefing Screen Printing to Survive in Niche Applications, which is based on this report, Smithers Pira print consultant Dr. Sean Smyth states: “Although under attack from new and innovative digital printing technologies, screen printing still maintains a competitive advantage in a few niche industries. Its survival will depend on its success in sustaining a dominant position within these industries.”

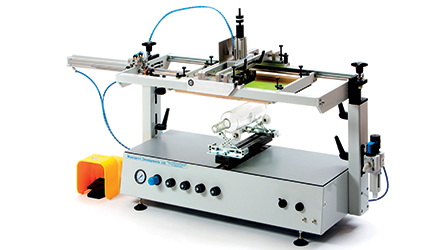

The Thieme 3010 automatic, flatbed, shuttle table screen printing machine has a 500 x 750mm print size, and can handle 50mm substrate thickness

He goes on to say that although screen printing cannot compete with the other printing processes in terms of speed and volume, it does still hold a significant market share: “In many ways it is the most versatile of all printing processes. The strength of screen printing is its ability to print almost any fluid onto any surface, being widely used in industrial decoration as well as graphics and packaging. It can print on practically any material, from conventional papers and boards to metals, glass, fabrics, and plastics, as well as printing directly onto irregular-shaped objects such as bottles, cans and ceramics.

“Screen printing has also remained a core technology for garment printing and continues to be the most popular technique for printing on T-shirts.”

New drivers

While the traditional principles of screen printing remain, they have been significantly enhanced by developing technologies and it is these that are driving its resurgence.

Screen printing equipment manufacturer and supplier HG Kippax supplies specialist machines and ancillaries to clients in 40 countries. Director, Bill Kippax, identifies a number of areas where new technology has been developed that is making screen printing competitive with digital printing: “Computer-to-screen, along with auto stencil developing and in-line screen reclamation has lowered the cost of screens per print. It has also allowed a faster print register set up as the four CYMK stencils are in exactly the same place on the screens.

The CP12 cylindrical screen printing machine, fitted with very simple tooling for printing glass bottles, is one example of the equipment developed and manufactured by Mascoprint

“Camera systems are also now available on screen print machines to ensure screen positions are simple and exact, being used to move the print table with substrate into exact register with the screen image.”

Camera systems are also available to check quality of print and eject the faulty prints Auto screen reclamation systems save on labour costs, chemical costs, and also guarantee a clean screen for re-stencilling.

Kippax elaborates: “Screen printers with modern multi-colour print lines with up to six print stations and who are using the new screen making and set up technology are running at 24/7 on a regular basis. With six colour print lines they can print CYMK, a special colour shade or a glitter ink and finally a UV spot or full colour varnish at 650iph on sizes of 1,600 x 2,600mm.”

Manufactured in the UK, the Clean Burn dryer, distributed by Global Print Solutions, offers increased productivity due to its faster drying speed, thereby enabling both time and costs savings. With the right dryer many quality and technical issues can be eliminated

Mascoprint Developments’ business has been built upon using screen printing for non-signage applications. The company’s first customers in the 1970s were printed circuit manufacturers. But since then they have made screens and supplied screen printing machinery for a diverse range of industries.

“For us, new developments are happening all the time, since almost every piece of equipment we supply has a bespoke element that can evolve into a ‘standard’, especially when designing tooling for cylindrical, tapered or oval articles,” explains director Yvonne Mason.

She continues: “Screen printing is a very reliable method of applying a controlled amount of substance with a high degree of accuracy and repeatability. Screen-printable media is generally thought of as ink but also includes thermoplastics, adhesives, metallised compounds, conductive pastes and sugar suspensions.

There is a combination of established and new technology in almost every project we undertake, using the 3,000-year-old screen printing process to apply new or unusual substances to industrial substrates”

“We bring together the appropriate combination of machine, tooling and screen (mesh grade/tension and stencil depth) to achieve the desired effect or satisfy a technical requirement. There is a combination of established and new technology in almost every project we undertake, using the 3,000-year-old screen printing process to apply new or unusual substances to industrial subs-rates.”

Indeed, this sector’s technological innovations, and growing demand for the quality and durable products it can output, has seen several specialist in this area thrive. One of these is Global Print Solutions, which in addition to the full range of equipment you need to get started in screen printing, also offers innovative products such as the DST (Digital Screen Transfer) system. This combines digital printing with screen printing and is described by director Mel Revitt as a, ‘turn-key solution that enables garment printers to produce their own transfers profitably, reducing stock-holding and wastage’.

Supplied by Global Print Solutions, the DST (Digital Screen Transfer) system, which combines digital printing with screen printing enables garment printers to produce their own transfers profitably, reducing stock-holding and wastage

In the DST system, artwork is printed digitally while, at the same time, films for the white and adhesive screens are printed. The two screens are then developed, following which the white is printed onto the artwork and cures. After that the adhesive is printed onto the white and cured, resulting in a transfer that is ready for application to any type of garment or material for decoration, product marking or labelling.

Also supplied by Global Print solutions is the Clean Burn dryer, which the company sees as a significant technical advancement in drying technology.

Global’s Paul Brook explains why this is such a fundamental area of consideration for the sign-maker: “The dryer is the most important piece of equipment in a print or sign shop. With the right dryer you can eliminate many quality and technical issues, such as ink curing, washability, fabric discolouration and scorching, temperature control and heat loss.”

Manufactured in the UK, the Clean Burn dryer offers increased productivity due to its faster drying speed, thereby enabling both time and costs savings.

Global Print Solutions supplies everything you need to get started in screen printing on a professional footing. Pictured: Its manual screen printing carousel features micro registration fitted as standard to each print head. Side clamps make a stable platform for the screens, while a bearing registration system ensures accurate repeatable registration on the 40 x 50cm platens

Fighting its corner

Among the niche applications in which screen printing still maintains a competitive advantage is the application of very thick ink films, high-opacity whites, metallic colours, and two-component ink systems for high performance applications.

This something the aforementioned Smyth highlights in his briefing: “One niche application of screen printing is high-opacity whites, with the relatively high viscosity inks used in screen print technologies better suited for handling the relatively heavy inorganic pigments used in white inks.

Screen print technologies can achieve much higher pigment concentration and therefore greater opacity”

“Digital print technologies face the ongoing challenge of keeping these heavy pigments in suspension in their low viscosity ink formulations and therefore struggle to compete with screen print technologies in this application. As a result, screen print technologies can achieve much higher pigment concentration and therefore greater opacity. To create sufficient opacity with a digital white often requires multiple layers to be applied, which is both costly and unproductive.”

Smyth continues: “Similarly to white inks, metallic inks use heavy inorganic pigments. Therefore, screen print technologies also have a niche application in metallic colours, with digital print technologies facing similar challenges in manufacturing metallic inks as they do in high-opacity white inks.”

Mascoprint has seen an increasing number of Universities using its equipment for research and development projects, even involving graphene as well as nanotechnology, and for sensor research into variable design and materials options.

“In addition, we have experienced an increase in high-end consumer applications, such as personalisation of luxury car interiors or professional camera lens filters. We are optimistic the continuous emergence of such niche markets will ensure the longevity of industrial screen printing,” affirms Mason.

For HG Kippax, the main developing area is in the industrial sector with growth in the medical, component printing and laminate advertising.

“What is pleasing is that education is investing in screen printing again. They say that hands-on technology gives a far greater training experience than computer education. It also allows people to move into manufacturing which drives our country forwards,” concludes Kippax enthusiastically.

O Factoid: By cutting shapes into banana leaves and pressing dye into the cut-out portions, early Polynesian Island natives were able to produce some of the first screen prints. This process transferred the stencilled design onto a bark cloth. O

Hearing from these wise industry heads, they explain that growth in these high-tech areas of screen printing is having a significant trickle-down effect on the technology that finds its way into sign-making businesses and dedicated print shops, which are becoming increasingly more efficient, productive, and capable of higher quality output. Clearly new technology is giving an ancient printing technique a new lease of life, albeit in specialist applications and niche markets, and so remains a viable process for printers and sign-makers to offer as part of their portfolio of services.

This also needs to be considered in light of two interesting trends. The first is seeing many marketers turn to screen printed products to fuel a growth in demand for retro and unique textile-based products from carry bags to baseball caps. The second is a renaissance in demand for typical screen printing products such as ‘one-off’ apparel designs for boutique fashion, tourist, and novelty stores.

So, it seems that despite being over-shadowed by its upstart competitor in the form of digital inkjet technology, there may be one more come back left in this ancient and evocative printing system.

Your text here...