Roland DG has developed its TrueVIS brand of print and cut devices to address the challenges facing today's sign and graphics company, while helping them also future proof their business

The people of Britain have once again exercised their democratic right, and the country ia now staggering on while the politcal elite sort themselves out. Among the hottest topics of debate in the campaigns for this election has been Brexit and the economy. While the ideologies and approaches may differ, both main parties believe only they have the solution to secure the economic future of the country in these uncertain times.

So while the winds of fate decide who will best drive progress and stability for Britain, this feature will weigh up the state of our own wide-format market, which is anything but uncertain as it experiences annual growth. Looking at the key trends, market insiders give their opinion on what the future holds for the sector, irrespective of who takes the keys to number ten.

Roland DG, a leader in integrated print and cut for 22 years, has proved once again its position in the sign and display market, with some very impressive results in a recent EMEA customer survey. Respondents included customers who have been using Roland devices for many years, as well as recent purchasers, with more than 4,000 customers across the region giving their feedback.

When asked about their wide-format ownership, 98 percent of Roland customers declared that output quality met their expectations, with nearly nine out of ten users responding positively in terms of the print quality they consistently achieved. Indeed, 98 percent of Roland customers also cited versatility and ease-of-use as key areas where their product is meeting expectations.

Additionally, reliability and low running costs were highlighted as key areas of satisfaction for Roland users. Such satisfaction levels are reflected in Roland DG’s global sales numbers, with over 116,000 integrated print and cut devices sold worldwide.

Gillian Montanaro, Roland DG’s head of marketing for EMEA, explains what is driving the market and its success within it: “For customers who want a true print and cut—two-in-one—device for space-saving, economy and versatility, or for those who want a separate printer and cutting device for further productivity, Roland has the perfect solution. Our market-leading integrated solutions are seamless, meaning that they are very simple to set up, and work right out of the box.”

Gillian Montanaro, Roland DG’s head of marketing for EMEA, explains that it is the need for versatility, economy, quality, flexibility, and reliability that continue to drive the majority of wide-format print equipment sales

A good example of this is Tony Lane, creative director of Think Image from Bristol, UK, who explains: “We have been a Roland DG customer for the past ten years and the ongoing support they offer and the reliability of their products has always been second to none. Every day, our Roland device produces a vast range of output —from vehicle graphics and wall graphics through to stickers and wallpapers—and everything in between. The set-up is easy, the maintenance minimal and the diversity of what you can achieve is simply staggering: we couldn’t exist without it.”

Montanaro concludes: “Roland DG continues to be the large-format printer of choice for sign-makers and PSPs worldwide. Our reputation has been built on our high-quality products and unrivalled levels of after-sales service. We support our customers with our user-friendly RIP, Roland Profile Center, true media versatility and consistently superior print output and have built up unprecedented levels of trust with our customers based on quality and reliability. Whether you buy an integrated print and cut machine or separate printer/cutter, you can be sure that Roland won’t let you down.”

Public demands

Talking to members of the industry well-placed to offer inside insights, one thing is clear: the wide-format market is anything but static. Consumer demand is driving development of ever-faster, more efficient solutions, while innovative technology creations are opening up new avenues for clients and end-users.

Dominic Fahy, Canon UK’s business group manager for display graphics systems and imaging supplies, says that his firm are consistently seeing greater demand for personalised print, as well as heavily reduced turnaround times across the board of wide-format production.

He continues: “40 percent of jobs now need to be produced in 24 hours and almost two-thirds within 48 hours. This higher customer demand coupled with fierce competition is leading to changing print dynamics, and printers who can differentiate and diversify their offering are set to benefit.

40 percent of jobs now need to be produced in 24 hours and almost two-thirds within 48 hours”

“Research shows that roll-to-roll printing is a growing segment and this, in partnership with the changing print dynamics, led to a technology gap in the market. Printers are requiring greater productivity, image quality, media versatility all with a reduced total cost of ownership (TCO). These have been instrumental market factors behind the development of Canon’s game-changing UVgel technology.”

The significance of reduced turnaround times in the wide-format sector is a point also picked up on by Ben Woodruff, sales manager at Inktec Europe. He comments: “Lead-times are ever decreasing meaning digital printers are looking to speed up their wide-format equipment to cope with customer demands. This is the reason why InkTec have introduced the new high-speed Jetrix LXi8 to give our many existing clients a product they can upgrade to.”

Inktec’s Ben Woodruff says that clients are aware of technological advances and increase their demands accordingly

When asked what comes first, new technology or increased customer demands, Woodruff suggests it is a chicken and egg question: “Our clients are aware of the technological advances in the wide-format sector and they appear to have increased their demands accordingly. We are seeing huge growth in direct to substrate printing hence the UV printer market becoming more saturated with more options than ever before coming from all over the world.

Therefore, it’s important that potential buyers of UV printers do their homework thoroughly prior to investing in kit.”

Looking to the future, Woodruff predicts more printer manufacturers branching out into different areas of the print industry: “Inktec have a few products in development which will take us into completely opposite markets to wide-format. Looking at FESPA recently, the textile market would appear to be flourishing with a whole hall full of manufacturers and suppliers.”

A textile trend

Indeed, it is the softer side of print that Brett Platt, textile product manager at Hybrid Services, pinpoints as a key sector being driven by technological development.

He explains: “The soft signage market in the UK continues to expand: having been a substantial growth sector on the continent in recent years, the UK and Irish market is catching up and growing strongly.

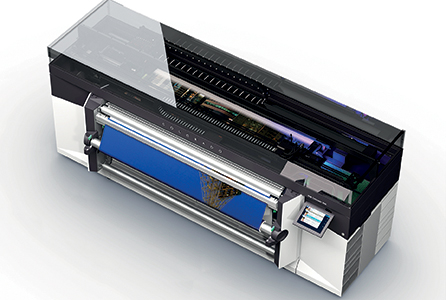

“Several factors are contributing to this; alongside customer demand, fabric development is also moving the market forward and the ability to print polyesters with an increasing range of ink technologies has made it simpler for printers to achieve, with products like Mimaki’s roll to roll UJV55-320 UV printer delivering grand format lightbox and exhibition graphics at a highly competitive hardware cost and with a single, simple printing process.

Hybrid Services states that products like Mimaki’s roll-to-roll UJV55-320 UV printer are delivering lightbox and exhibition graphics at competitive hardware costs

He continues: “New fabrics and printer technologies are also opening up the soft signage market with polyester materials for backlit displays, flags and light-weight sheer fabrics for banners and hangings giving the market more choices than ever before. These advancements combined with ever-faster and higher-quality printers create an ideal environment for the sector to progress.”

These advancements combined with ever-faster and higher-quality printers create an ideal environment for the sector to progress”

As we consider the ability of new technology to influence trends and steer the market onto a different course, Canon’s Fahy turns again to the company’s new UVgel technology. Canon used FESPA in May as the launch pad to introduce the first device built on UVgel technology: the Océ Colorado 1640, a 64" roll-to-roll wide format printer.

Fahy comments: “Just as the demands of the market helped shape the UVgel technology, UVgel will shape the market, in that it is a disruptive technology opening huge new opportunities for customers. It’s up to four times as fast as water-based printers. The Océ Colorado 1640 is faster than any other printer in this segment, with a top speed of 159sq m/h for applications such as billboards or outdoor banners. Even at the highest level of quality for close-up indoor applications, the printer operates at 40sq m/h.”

Canon claims the machine pulled in large crowds to the hourly demonstrations at FESPA, with orders secured from signage and graphics producers here in the UK and across Europe. Fahy suggests the system meets peak production requirements of customers, producing high volumes in short turnaround times on a wide variety of media.

He continues: “The technology advances the industry in a number of ways. One example is that Canon UVgel ink is instantly ‘pinned’ on contact with any substrate, resulting in a highly controlled and precisely positioned dot with minimal gain. By minimising ink spread and coalescence on the media, the required ink volume is used in each pass, delivering rich, intense images.

“Another is that a low temperature LED-UV curing system moves independently from the printing carriage, enabling uniform, post-print UV curing that further contributes to print speed and print quality. The cured UVgel prints are instantly dry and ready for finishing or laminating, ideal for businesses handling jobs demanding fast turnaround and installation.”

Fahy continues: “UVgel and the Océ Colorado 1640 are just the latest examples of Canon’s commitment to innovation. We have a clear focus on delivering solutions and services to help customers build better businesses.”

Looking to other areas of the market, Fahy identifies posters, decals, banners, and wall coverings as key growth sectors. He comments: “The Océ Colorado 1640 is suitable for all these. UVgel is a low-heat process using LED curing, ensuring minimal media distortion and extending the range of printable substrates, including thin and heat-sensitive media. Furthermore, UVgel ink contains no water, which significantly reduces media swelling, improving dimensional consistency.”

Canon used FESPA in May as the launch pad to introduce the first device built on UVgel technology: the Océ Colorado 1640 roll-to-roll wide-format printer

Platt from Hybrid Services also sees the interiors market as once to watch, alongside soft signage and the fashion market.

He explains: “These sectors are expanding, with the polyester fabric suppliers already introducing new fabrics. Materials that look and feel like silk, cotton, linen and velvet yet are manmade allow print providers to output a range of fabrics with just the one printer and ink technology.

Hybrid claims it is an exciting time to be so heavily involved in textile printing, as the soft signage and fashion markets continue to expand

“However; the recent announcement of the dual ink upgrade for Mimaki’s hugely popular Tx300P-1800 direct to textile printer means the company’s pigment and dye sublimation inks can be loaded simultaneously for printing to natural as well as man-made fabrics and, as they share a similar fixation method, are able to be printed and processed very easily.

“It’s an exciting time to be so heavily involved in textile printing and with Mimaki’s broad range—both in terms of productivity and price point—we’re in a very strong position to really deliver local-to-market manufacturing across most sectors. Sportswear, fashion, homeware and the promotional markets can all benefit from a quick time to market and with hardware delivering the volumes required at competitive costs, the opportunity is there to make it work.”

High-tech horizons

Looking to the future, Platt predicts that developments in technology will continue to drive change and innovation in the market, with some key advancements potentially just around the corner:

“Printing hardware is constantly developing with machines getting faster and powerful technologies such as nozzle dropout detection on the Mimaki TS300P-1800 sublimation printer enabling the machine to run unattended. Equally, we’re seeing impressively specified entry level machines being introduced and the new Mimaki TS30-1300 will deliver quality, productivity and ease of use at a very attractive price when it becomes available in the very near future.

O Factoid: The first dedicated industrial inkjet printer for signs and large-format graphics applications was developed by Metromedia for global roll-outs of billboard signs. O

“Competitive hardware pricing is also being matched with economically priced inks—and Mimaki’s Sb410 sublimation inks sit at a price point that make sublimation printing one of the most cost-effective ways of getting printed designs onto material.”

Canon’s Fahy agrees that the future of the industry will be determined by the techy people working behind closed doors, creating the small improvements that make a big difference to the market: “The IT revolution will continue to enable digital printing to grow and offer up a wealth of new opportunities to print-service-providers. The market is telling us that volumes are growing, that there is a need for faster turnaround times and for prints that don’t need to dry. Automation will also continue to play an ever-increasing role within the industry as the demands of customers continue to grow.”

Your text here...