With demand for increased production, it is often the case that ‘bigger is better’ when it comes to wide-format printers

As the signage industry moves from strength to strength, many expanding medium-sized businesses have found the need for massively increased production. Whilst many smaller roll-fed machines are perfectly capable of high quality output, there is a certain truth in the old adage ‘the bigger the better’. Certainly at this year’s FESPA, manufacturers across the world were bringing out the big guns in full force to show the opportunities made available by these impressive feats of engineering.

Nowadays, sign-makers often find themselves choosing between a high-cost flatbed, for flexibility of substrate handling, and a large roll-to-roll for high production wide-format printing, as their main investment. However, printers over 3.2m wide (or ‘superwide’) can still seem like an industry gimmick. At a potentially high price tag and large footprint, many sign-makers may believe that these machines are really not for them and would not offer the greatest return on investment.

Thinking big

Agfa UK’s wide-format inkjet manager, Steve Collins, could not disagree more. He says as potential applications for sign-makers widens, a superwide format printer is starting to look like the best option for many companies.

Looking at industry trends as a whole, Collins says: “Many medium-sized large format companies are looking at ways to print wider flexible signage such as building wraps, POS posters, and larger backlit applications. Another area that is creating an interest is the requirement to print onto textile products for the use of indoor POS applications.

“Along with the added versatility and width comes the demand for higher productivity. For these types of companies, a 3.2m wide dedicated UV roll-to-roll printer will address these requirements.”

Collins has identified the movement of some sign-makers towards having a high production and flexible print room which, he says, can be bolstered and improved by the addition of a superwide roll-to-roll.

Collins says: “In many cases, a medium-sized printer may already have a number of solvent roll-to-roll printers alongside a flatbed system and they are looking to focus on an increase in roll-to-roll printing. This is where a dedicated UV roll-to-roll fits nicely into their growth plans.”

“As many will already know from the flatbed technology, UV offers a much lower ink consumption per square metre compared to solvent and water based technologies,” continues Collins. “Other benefits include the capability of printing 2 x 1.5m rolls simultaneously with an optional dual roll system to allow for additional productivity when printing smaller rolls and the ability to print a white ink to extend the number of applications that can be supported.”

As fabulous as these additions sound, many sign-makers will still claim a superwide machine is far out of their price range. However, Agfa’s offering to the market, the Anapurner M3200i, has taken this into account.

The Anapurna M3200i is positioned at a price and performance that surprises many people”

“The Anapurna M3200i is positioned at a price and performance that surprises many people,” says Collins. “The Anapurna M3200i combines speed with an exceptional level of quality for a price or £128,000. In addition to the six colour version, there is also a version with four colour plus white that offers a high density white ink for printing onto coloured and transparent substrates.”

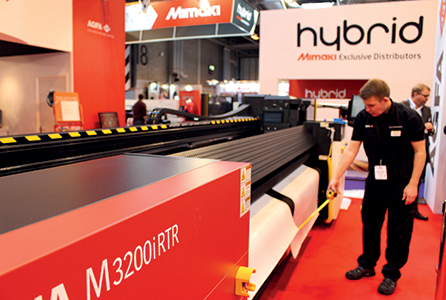

The Agfa Anapurna, coming in at a cost of £128,000, can produce up to 123sq m/hr or 33sq m/hr in standard mode

The Anapurna M3020i can produce up to 123sq m/hr or 33sq m/hr in standard mode. Using Konica Minolta 1024i printheads with a 12-picolitre drop size, the machine is capable of a resolution up to 1440 dpi. The Anapurna takes media of a 0.2mm maximum thickness as well as offering an option for printing to mesh without a liner.

Collins also takes notes that, ‘It isn’t all about the printer,’ as the best way to get the best out of a machine like this is to have a proper workflow system set up to run the beast. This is why Agfa has created a specific workflow and colour management system purely for wide-format printers.

He says: “As Agfa witnessed in the pre-press environment, customers expect improved quality, consistency, and reliability throughout the production cycle. Agfa has a history of creating workflow and colour management systems for pre-press, so it made sense to create a version for the wide-format marketplace called Asanti.

“Asanti is not only a RIP with full blown colour management capabilities, but can also be upgraded to a central production hub with work flow automation to drastically reduce the lead time from the job starting the production cycle to the final printing process.”

Collins sees the future of superwide format focusing on successful machine integration into workflow, and supporting different MIS solutions. Also, new technology is just around the corner, so watch this space.

Collins says: “LED technology, for example, is continually being assessed, and will be introduced when ready to offer the benefits in both speed and quality. Agfa also has plans for a 5m wide UV roll-to-roll based on the same quality as the M3200i due for release later in 2015.”

The future is textile

John de la Roche, national sales manager for sign and graphics, at exclusive UK Mimaki distributor, Hybrid Services, has noticed similar trends in sign-makers seeing superwide format as a viable investment option, and has noticed how the machines directly cater to a number of increasingly lucrative markets.

The overhead graphics on Hybrid’s 2015 SDUK stand were produced on a lightweight polyester with a slight stretch element meaning they appeared crease-free

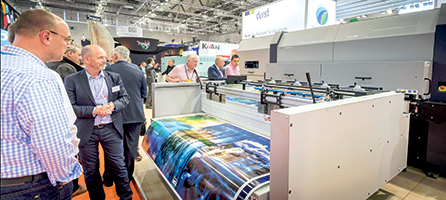

He says: “In the last few years there has been an increase in sign-makers investing in superwide format hardware to undertake projects such as large exhibition graphics and high-end retail PoS involving soft signage elements.

“The exhibition industry continues to grow and exhibitors are demanding increasingly prodigious graphics to wow crowds and draw potential customers to them, which requires printing continuous reams of fabric on super-wide kit to scale the frames of sizeable exhibition stands.”

O Factoid: In 1991, Graham Nash—of Crosby, Stills, Nash and Young fame—was one of the first to use wide-format print technology to build a dedicated digital fine art photography printer for his company Nash Editions O

De la Roche sees the solution to growing demand to be a case of bringing as much print work in-house as possible, especially including large-format applications.

“In order to keep up with growing demands, print service providers are looking to invest in bigger kit in order to compete on large-scale projects and not lose profits through outsourcing,” he continues. “As areas such as retail PoS soft signage continue to boom resulting in potential workloads for printers offering super-wide production capability to flourish, there is greater need to bring superwide hardware in-house.”

In this way, Mimaki has identified sublimation printing as a solution to wide-format printing demands, launching the JV5-320DS as a versatile machine for growing sign-makers.

The Mimaki JV5-320DS is a 3.2m wide sublimation printer that prints directly onto polyester for applications such as light boxes, flags, and retail PoS

He says: “The Mimaki JV5-320DS is a 3.2m wide sublimation printer that prints directly onto polyester for applications such as light boxes, flags and retail PoS. With a top end of over 60sq m/hr and extremely high print quality, it’s a proven solution with a significant UK install base.

“It has the capacity to also print to paper for transfer, allowing stretchy fabrics to be imprinted—like the overhead graphics on Hybrid’s 2015 SDUK stand, which were produced on a lightweight polyester with a slight stretch element meaning they appeared crease-free.”

De la Roche says that Mimaki also has a solvent option at 3.2m wide—the JV5-320S—which is perfect for printing wide banners. He notes that this is still quite a specialist area of print, but nevertheless a growing market worth keeping an eye on.

De la Roche concludes that now the wide-format train is gathering momentum, customers will be looking more and more towards superwide format printing as a way to stand apart from the crowd with stunning visuals.

He says: “The demand for soft signage is on the increase so there will be a steady increase in demand for superwide printing via dye sublimation or direct printing to textile depending on the material used.

“Applications such as exhibition graphics, PoS displays, and building wraps are getting bigger all the time, so there will be natural growth. Airports are a great example where large displays are utilised for everyone to see.”

Grand scale productivity

The kings of the superwide format market are surely Durst and EFI, two players that have bolstered their arsenal of machines to provide for most wide-format printing needs. EFI hit headlines after launching what it claims to be its ‘fastest ever’ 3.2m wide roll-to-roll, the Vutek HSr Pro. With a production speed range of 223-297sq m/hr, the Vutek clocks in a hefty production rate, and offers six-colours plus white to customers producing a variety of graphics and banner displays.

Durst has been one of the forerunners of superwide printing, with a range of grand format machines, both flatbed and roll-to-roll, that have been supplying the industry for over a decade.

(Above & below) Durst, one of the leaders in the superwide format market, had its Water Technology championed at this year’s FESPA

The Rho machines come in both 5m and 3.2m wide versions, all of which put productivity at the top of the bill. Durst’s 5m wide machines, the 500R and 512R, produce print up to 350sq m/hr. The former offers a 600dpi resolution with CMYK, and the latter, 900dpi, offering a different print array with a 12 picolitre drop size as minimum.

The Rho 312R, on the other hand, is the fastest of its size, producing up to 240sq m/hr. Durst claims it reaches a new quality standard, ideal for industrial backlit and fine art applications.

Peter Bray, managing director of Durst UK, makes a strong claim for the superwide format print market, which he says offers even more than meets the eye. He says: “Productivity, reliability, and quality of the systems is obviously key. However, it’s not necessarily that customers specifically want 3.2m width, it’s often the versatility.

As an example, if the machine has a 5m wide configuration, it enables customers to have three 1.6m rolls on a machine, and that opens up huge new business opportunities for customers.

“Sign-makers are demanding higher productivity, reliability, and versatility on their superwide systems, as well as wanting to use them for new applications. Take the fabric backlit market, on our Durst Rhotex 3.2m wide they can produce instore graphics on a one-piece unit, creating backlit fabric products also using Durst Dye Sublimation-Ink set, CMYK.”

Bray, like de la Roche, has noted the growing influence of the textiles market, which has prompted Durst to provide the kind of productivity on a machine which will meet customer demand.

He continues: “One growing market is textiles, which is why we have been expanding our direct printing portfolio with dye-sublimation technology, for example with the Rhotex 180 TR. Printing on sublimation paper and the transfer process using a calendar minimises production expenditure and enables those not in the industry to enter the field of textile production. The printing system is especially suitable for polyester and polyester blends used in clothing, household textiles, and soft signage.”

During FESPA this year, Durst championed a new kind of technology directly applicable to the soft signage large-format market, which Bray sees as making the manufacturer stand out from the crowd.

He says: “Durst Water Technology is our new unique selling point in the market, which will be complementary to our existing product range, and yet again we find ourselves as the innovative leaders in large-format printing.

“This is a groundbreaking innovation for soft signage and was essential to establishing sustainable and odour-free large-format products at the POS. With the new development of the Rho WT, we can expand the range of applications to include classical LFP applications and access new market potential in the interior segment, as well as packaging and POS with ‘green’ products. We also constantly develop UV printing and can offer a larger media flexibility and a higher level of automation.”

Bray sees this concentration on ‘green’ production as the way forward in the future for wide-format printing, which is worth taking note of in the ever eco-conscious environment. He says: “Many visitors to our stand at the recent FESPA show commented on the ‘game-changing’ nature of Durst Water Technology, part of a long-term strategy to provide an eco-friendly alternative to UV-curing inks.

Many visitors to our stand at the recent FESPA show commented on the ‘game-changing’ nature of Durst Water Technology, part of a long-term strategy to provide an eco-friendly alternative to UV-curing inks”

“We would envisage in the future this ground-breaking innovation being available roll-to-roll systems and opening up a new world of commercial opportunities for our expanding customer base.”

Though the superwide format printer will not be suitable for every sign-maker and print service provider, depending on the kind of markets they cater for, the size of their production facilities, and their budget for energy usage, it is nonetheless becoming more of a staple for growing businesses to consider ‘going superwide’. Clearly, these machines are at the forefront of an expanding market, whether that is in backlit banners and fine art prints, or textiles and soft signage. Perhaps it is worth keeping an eye on where the biggest feet are treading to see what may follow in years to come.

Your text here...