The changing face of technology

The changing face of technology

Probably the most ubiquitous source of lighting for signs is the sun. Chief among its limitations is its limited availability. Once it has dipped below the horizon, the light it casts vanishes.

Solutions that provide lighting into the hours of darkness for signs and displays are well-known and have evolved from very humble beginnings. Ever since the first commercial signs began to appear, efforts have been made to extend the hours during which they function, or to improve the overall impact they achieve, by illuminating them. Given that lighting is as much about contrasting with surroundings as it is about power in absolute terms, this did not take much effort or particularly evolved technical design in the early days of lit signs.

O Factoid: Signs were almost exclusively front lit right up to the mid-twentieth century. Electric lamps emitted high levels of heat, glass was too expensive and delicate to use for light boxes, and transparent plastics with very high melting points were yet to be invented. O

Early signs were, for all practical purposes, exclusively front-lit. Typically painted on walls, hoardings, and boards, they benefited from simple light sources of the era, arranged so as to minimise shadows cast by roughly textured surfaces and to achieve a reasonably even distribution of the available light. In the hours of darkness, the light would come on and, surrounded as they were by poorly lit ambient matter, the signs shone out of the darkness.

Neon switches on

Neon and its arrival represented a pivotal moment in the development of the modern night-time signscape. Instead of relying on pale apparitions looming out of the darkness that only resolved themselves into painted signs once eyes had adjusted, advertisers could position what amounted to branding beacons wherever the eye might alight. The impact was huge on the industry and on the landscape.

Rather than grudgingly reflecting back to the observer, a mean portion of the light falling upon the sign provided by an indifferent light source, neon lighting emitted bright light from with-in itself.

Gasses contained in glass tubing, which was skilfully bent into letter-shapes and excited by electrical bombardment, glowed—and it glowed brightly. Different gas mixes and interior coatings on the glass tubes evoked different colours. Fast switching states introduced the possibility of basic animation. Practically at the flick of a switch, signs were defined in an iconic sense and competition between them had arrived.

Attractive though it was, and is, in many respects, neon had some baggage to shoulder. It is unquestionably some-thing that only a highly skilled set of hands can produce to an acceptable standard. It is fragile too and requires specialised handling. The voltages needed to make it glow would be sufficient to animate the dead and it needs careful design consideration so as to maintain the legibility of the sign in its naked state. The other factor on the horizon is that mercury will be banned in the production of neon from 2020, creating a big question mark over its future unless alternative methods of generating its fantastic colours can be developed.

Fantastic plastic

Until acrylic sheeting came along, the sign industry did not have a viable and readily available source of durable materials that could be back-lit. Once acrylic arrived, and techniques for fabricating it had been explored and perfected, it was put to work in well-designed alliance with neon so defining the technical foundations that many more recent high-profile illuminated signs have built upon.

Neon as a source of illumination for fabricated signing has obvious appeal. It can be bent to shapes that do not need to be too pretty in the naked state and it is powerful enough to yield finished signs that really do cut through the visual clutter. Limitations apply though and the highly specialist manufacturing needed has motivated people to look for alternatives for years.

In a more contemporary setting, the role of illumination still exists to serve the needs of signs that have to work around the clock. The use of light though is today taken further. It serves to distinguish signs by design rather than simply by out-gunning a neighbouring sign’s firepower. Light sources have diverged and evolved into new roles. The lit signscape today is more vibrant, more colourful, and has more potential to generate growth within its sector thanks to its appeal.

What the industry might consider to be ‘conventional’ illumination sources have lost appeal beyond pure utility. A fabricated signbox constructed from extruded components and then filled with an array of fluorescent tubes is today a product of a recent age past. Outside the specialised areas of large billboards and other systems with typically tensioned faces, the ‘tube’ is probably past its finest hour.

Given the diverse venues that signs now occupy and even the confused nature of what a ‘sign’ actually is, light sources have had to evolve. And anyone who casts themselves in the role of ‘sign-maker’ has had to evolve too.

Taken to the edge

David Whitchurch is the founder and managing director of Master Products, based in Woodham Ferrers. His company trod the path of a traditional sign-maker for many years, but has evolved to serve the needs of its customers to the point where it might, despite its billing, be considered an artisan working with light. Master Products’ medium is Edge Lit Signing and Decorative Panels.

Edge lighting isn’t new. Oddly though, the stunning effects it's capable of achieving are new to many of the eyes that alight upon it”

Edge lighting is not new. Oddly though, the stunning effects it is capable of achieving are new to many of the eyes that alight upon it. Within the reach of practically any modestly equipped sign company working with acrylic, the output is very commercial and attractive. Master Products’ competence achieves a new level of quality by working with glass, a much more difficult medium to exploit in this application.

The effect of edge lighting exploits the fact that light introduced into the edge of a panel having two plane and substantially parallel surfaces will bounce around until it decays or encounters some interference in the sheet’s surface. When that happens, the line, letter shape, or whatever is interfering with the light will glow powerfully from within itself.

Light appears to emit from within the body of Master Products' Edge Lit Signing panel, with no visible light source

As a source of illuminated signing, edge lit panels have the potential to be used in a huge range of applications. David Whitechurch explains: “Edge lit signs achieve an immediate and profound effect on people who see them for the first time. To see lit features apparently suspended in glass with no obvious source of illumination is a novelty to most.

“We actually sculpt glass into deeply incised figures and shapes so anything, within reason of course, which can be imagined in such a medium can be utterly transformed by edge lighting.

“We work with toughened glass which is particularly good at handling the light and the carving process. The output is clean and easy to maintain and, I have to say, dramatic.”

Enter LEDs

Getting the powerful lighting the effect needs into the relatively narrow edge of a panel demands a specialist light source. Enter LEDs.

LEDs have evolved from the relatively bulky discrete components used as indicators and signals in just about every domestic appliance in recent history, to the point where they are now rapidly and widely displacing other sources of light in just about every lighting application known.

In the case of edge lit panels, LEDs are typically to be found arranged conveniently on a strip of flexible material that carries the lighting component itself, some supporting components and tracks to handle the low voltage power supply needed to power the lamp. A novel extrusion is used to house the components and obscure them from sight. The net effect is of light apparently emitting from within the panel itself.

Finding and using discrete sources of light has long been the sign industry’s grail hunt. On the journey, many exotic solutions have been identified and summarily abandoned. One that is located outside the mainstream but that is leveraged to brilliant effect by those who understand it is the Electro-Luminescent lamp.

Exotic technology

‘Lamp’ may be a misnomer. EL, to use the short-form, is encountered, in an infinite variety of sizes and some odd shapes, in the form of a sheet-like material, not unlike a piece of opaque polyester film with an off-white or pinkish hue. The film is thin, not usually even a millimetre thick, very flexible, easily bent around a tight radius, and normally glossy. A couple of wires emitting from one of its edges betrays its specialist application.

When connected to a source of high-frequency electrical current, EL lamps emit even light from within the body of the film”

When connected to a source of high-frequency electrical current, EL lamps emit even light from within the body of the film and routinely cause a jaw-dropping moment for those seeing this apparently alien light source for the first time.

The light produced by EL lamps does not impress as being particularly bright but, in relative terms when surrounded by low lighting levels, it really does pump out.

Mike Hardcastle runs Light Tape UK, based in Barnsley. The company is a noted exponent of EL. He believes that the technology has much to offer: “EL lamps radiate light in a narrow frequency range that’s best flattered by surrounding it with sources of artificial, rather than natural light.

This lighting installation spells out Foster Court in Morse Code. Light Tape EL used to brilliant effect

“The lamps themselves are very tough and recyclable and they’re easy to incorporate into places that conventional light sources simply don’t fit. Our lamps are engineered from very high quality components. The phosphors that emit the light are made by Sylvania, the substrate is from Dupont and the encapsulation parts originate from Honeywell.”

Ultra flexible EL lamps emit light from within and are cool to the touch. Pictured: Light Tape UK is a stockist of the technology

In practical terms, useful signs can be lit from within by EL lamps and fast switching means that basic attention grabbing techniques work well. The lamp is such a novel thing to most eyes though, that it frequently finds a venue in the role of accent lighting. EL’s compact form factor and flexibility ensure that it’s never far from the thoughts of lighting experts when really challenging locations are called for.

Location, location, location

Challenging locations sometime call for a really inventive approach to lighting and that is exactly what Signscape and Signconex deliver in the EcoVision range.

EcoVision, a range of premium quality illuminated notice boards, really does deliver an inventive solution. EcoVision notice boards are illuminated, but using energy collected and stored during daylight conditions when the sun is shining, and which is released to power the units’ LED lighting when the sun has set. Added to its sophisticated approach, is an integrated sensor which activates the illumination only when movement is detected within a 4m arc of the board, ensuring there is always plenty of energy required when it is needed most.

This Eco Vision system uses off-Grid Lighting using stored electricity from solar energy

The obvious benefits of such an approach make the EcoVision range attractive from the point of view of its eco-friendly, zero running costs. There are some less obvious benefits the novel solution can claim too. Jamie Moore, the company’s marketing manager explains: “Customers are attracted to the EcoVision range because installation is free of the disruption and costs involved in delivering mains electricity to an external notice board. Remote locations or places where disruption to established or protected structures all benefit hugely from the reduced installation requirements.

“Since its inception this product has gone through several generations of development, to arrive at a specification that delivers the best functionality and value for customers. The latest models of solar powered Eco-Vision Notice Boards offer the best performance yet, and we are very excited to see this high quality, eco-friendly illumination being integrated in our customer’s notice boards during 2015 and beyond.”

There is a lot of interest in solar sources of power as witnessed by the amount of panels on domestic dwellings that have appeared recently. Low current LEDs have made sense of this technology and its future would seem to be assured given the very low costs once the initial installation has been paid for.

The next neon

For as long as neon lighting has lit up the sign horizon, sign-makers have sought to replace it with something that is easier to handle and to produce. With a question mark hanging over neon’s green credentials, the hunt is on in earnest and solutions are out there to be found. Notable among them is Neon-Plus from The Sign Group.

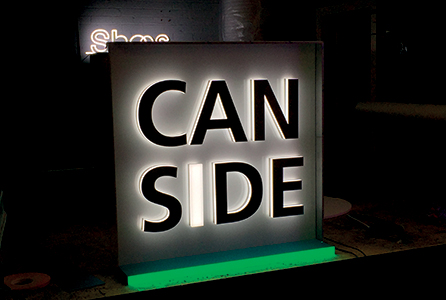

Complete with authentic fixings, NeonPlus from The Sign Group heralds a new lighting epoch

NeonPlus has LEDs at its heart and achieves a simply brilliant overall effect. The construction technique yields lit letter-shapes, logos, and any other detail needed, that look, even to trained eyes, like complex fabrications lit from within by naked neon elements.

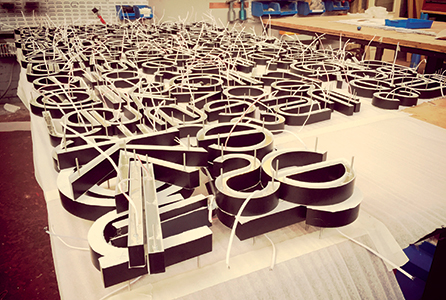

Fully fabricated NeonPlus lettering with lighting integrated - ready to install

Construction is as brilliant as it is inventive. It starts with opal acrylic, thick enough to yield a 25 to 30mm deep return and then machined using a powerful Tekcel router to produce a seamless component ready to accept an array of 24V LEDs. The component can then be capped with a chosen letter face to produce an extremely robust lit letter in its most basic form.

There’s no practical limitation imposed on NeonPlus in terms of the fonts that can be realised and it fits into comfortable alliances with practically every popular material used to make signs. So if your application demands a particular colour for the return or faces, then all you have to do is ask for it. Metals too are supported by the concept.

NeonPlus really does take light output to new highs by using dense arrays of 24V LEDs. It has no need to apologise for light output when compared to neon. LEDs have another trick up their sleeves too that NeonPlus will exploit—colour range.

By using RGB LEDs and by tuning the ratio of light output by each of the Red, Green, or Blue components, practically any colour can be extracted including warm and cool shades of white. Achieving such a gamut and doing so in such a finely adjustable way is beyond the practical capability of neon and so NeonPlus, in effect, puts a whole new palette at the disposal of The Sign Group’s customers.

Halo Lighting with NeonPlus LED powered lettering from The Sign Group

Ian Hoole of The Sign Group explains: “NeonPlus is an incredibly versatile technology that removes at a single stroke many of the limitations imposed on design, technical and artistic, by traditional neon. We now build letters safe in the knowledge they will reach our trade customers in one piece and will work immediately they’re plugged in.

“The lower voltages involved make for easier installation and we’ve not sacrificed brilliance in return. Neon-Plus has really changed the way we approach sign fabrication. It’s a better way to make illuminated signs.”

NeonPlus will unquestionably erode what was once an exclusive position occupied by conventional neon—it represents a new epoch in sign lighting technology”

The Sign Group distributes Neon-Plus to the trade and its website makes the point that design choice is as big a motivation in using it as a lighting technology as replacing neon for its own sake. NeonPlus will unquestionably erode what was once an exclusive position occupied by conventional neon—it represents a new epoch in sign lighting technology.

Pushing the envelope

Sign and Display Lighting probably belongs, in the not too distant future, wholly to evolved LEDs. Just like the 100W light bulb is going out all over the world, other forms of illumination that cannot that cannot deliver LEDs’ appeal in terms of output given, input needed, and sheer application-led versatility, will be eclipsed.

The sign and allied industries have rapidly become comfortable dealing with the new technology and its cost in real terms has fallen. Working with a new class of lighting has yielded results that perform better for end users over the lifetime of the sign or display. Maintenance needs are fewer, designs less constrained.

It falls now to the industry to push the performance envelope and extract the best signing solutions possible for the world we live in and the customers we serve.

Your text here...