The latest adhesive tape systems are as at home bonding sign framing systems to rough brick as they are too high-energy surfaces such as smooth walls, making them an increasingly common replacement for fixed hanging systems in areas such as retail spaces that are regularly redesigned

The materials sign-makers use to build signs have changed in recent times, with wood, foam, specialist metals and composites providing a lighter, more flexible and more cost-effective solution. These products require a more refined and technical fixing because rivets and screws can easily cause damage. In this environment tape and adhesive solutions are essential and while this can take some of the professional skill out of some jobs, such as welding, the need for high quality and reliable adhesives are clearly essential.

INDASOL is one of the UK’s biggest tape and adhesive providers, which specialises in the signage industry. Martin Sadler, director of INDASOL, explains that the latest technology under development is being driven by specific customer demands: “We see ourselves as a true one-stop-solution for bonding, fixing and sealing. Sign-makers are increasingly looking for invisible fixings with no visible front fixing. We provide advanced adhesive and tape solutions to replace rivets, welding and screws. Sign making is a professional service and our products compliment the final product produced.”

Sadler adds: “People that have jumped into the sign industry with cheap tapes and adhesives have done a lot of damage to the reputation of these excellent fixing solutions. Of course, there will always be those that offer inferior products at lower costs. But for signage that has already demanded a significant investment and that needs to be in place for a good period of time, tried and tested tapes and adhesives will always add value to a solution.

“Our tapes and adhesives can ensure signs remain in place and looking good for 20 years or more. We can also offer a broad range of both structural and technical solutions whatever your sign-making requirements.”

A tube of glue might only be a few pounds, but if the sign is worth £5,000 it is worth taking a bit of time to get the right solution”

Sadler continues: “We have a broad range of products that are available off the shelf with next day delivery and a fast and responsive service. We also offer technical support on- and off-site and have experts that will visit the customer to see the application and recommend the best solution. We believe this support is essential—a tube of glue might only be a few pounds, but if the sign is worth £5,000 it is worth taking a bit of time to get the right solution to enhance the integrity of that sign.”

INDASOL’s products include INDASOL 912LX, a two-part adhesive designed specifically for delicate surfaces such as BCP, ACM, and Di-Bond. This product does not create any read through on the front face of the sign. INDASOL UHB9120G is a structural bonding tape designed specifically for bonding channel to the reverse of signs to replace rivets, screws and welding. INDASOL says this works exceptionally well on cold surfaces and on powder coated metals and can cope with climatic changes as well as high weight loading.

NDASOL has a compressive range of adhesive solutions. The company’s technology is constantly adapted and evolved by drawing on feedback from its customers

Sadler concludes: “As well as next day off the shelf service, we can also slit desired widths and lengths to meet our customers needs. We also have a full range of tape and adhesive systems to use, so if a customer would like a product to be removable at a later date, we can achieve this. Equally for long-term structural bonding, we have products for this too. Basically, if something needs bonding or fixing, we have a product to do it.”

Stick with it

The drive by sign manufacturers to use thinner, lighter gauge, more ecofriendly, and cost effective substrates in the production of signage—coupled with the requirements of aesthetic quality—is a challenge that has been met by Innova Solutions for the past 13 years. Gary Bradley, process improvement manager for the company, comments: “We offer a range of aesthetically pleasing, durable, secure and reliable high strength bonding tapes and structural adhesives to bond metals, industrial plastics, glass and aluminium composite materials (ACMs), without compromise. Furthermore, in keeping with the requests of our customers many of our technologies are leading the way in terms of their ecofriendly credentials.”

The increased use of ACM’s in the market has led to ongoing issues when bonding mechanical fasteners to the rear of the sign. Conventional two-part structural adhesives exhibit an exothermic (heat) reaction upon cure, which in turn causes differential expansion and contraction between the aluminium outer and polyethylene inner sandwich of the ACM. On full cure this causes a read through distortion mark on the front face of the sign.

“Working in conjunction with our manufacturing chemists, Innova Solutions developed NovaWeld SignFix 33, a product that cures without the heat and associated shrinkage, thus eliminating unsightly marks on the sign face,” adds Bradley.

O Factoid: Richard G. Drew (1899-1980) invented masking tape and clear adhesive tape (also called cellophane tape, Sellotape or Scotch tape). Drew was an engineer for the 3M company. O

Bonding to low surface energy materials such as powder coat overspray has often required the additional steps of further abrasion and priming. These additional processes are both time consuming and costly.

Bradley continues: “NovaBond LSE 80 is an ecofriendly, solvent free bonding tape that gives incredibly high peel and shear values, normally with-out the need for further surface preparation.”

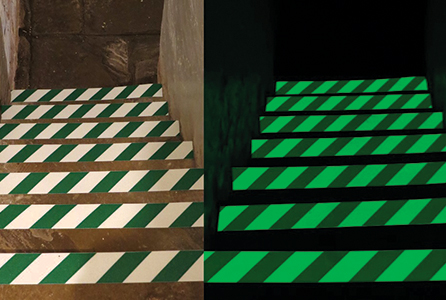

One of Innova Solutions’ most exotic products is Novaglow tape, which is designed as a durable solution specifically for applications that, for instance, require high-brightness in emergency situations

Another key consideration in this field is that conventional methods of laminating plastics have involved dichloromethane welding cements that have carried the documented health risks.

Bradley concludes: “In seeking to reduce the complexity of COSHH assessments and comply with EC regulations, Innova has launched a range of dichloromethane and phthalate free laminating adhesives, without compromising final product quality. Our invisible laminating adhesives cure by the passage of natural light through at least one of the substrates, producing a bond in minutes. The lamination can then be machined and flame polished as desired.

“As active members of BSGA we aim to stay at the forefront of an ever changing industry. Our products are used by the leading companies within the industry due to their durability and reliability in meeting customer needs. We remain keen to work with both existing and new partners on a consultative basis to deliver a range of cutting edge products, fully supported with independent testing.”

On the tape side, Innova Solutions has recently launched a new range of NovaTough DuraLine Anti Slip floor marking tapes. With an over-laminated, embossed clear layer, Innova claims the tapes give more protection to the printed material than any other printed floor tape. They are designed for ramps, steps, staircases, platforms, warehouses, corridors, and walkways in both manufacturing and commercial environments and Innova says they are proven to reduce injuries and claims caused by slips, trips and falls. All the DuraLine range is BGR classified to R11 for slip resistance for use as a floor graphic.

Glenn Dunleavey, managing director of Innova Solutions explains the impetus for founding the range: “DuraLine was developed in response to customer demand for a very high quality product with excellent aesthetics and durability that had inter-nationally recognised safety accreditations. We think the robust construction of the DuraLine range, coupled with the excellent print quality really fits the bill.”

The new series of products also includes the NovaGlow DuraLine, which provides high glow photo-luminescent technology. Dunleavey adds: “Additionally, NovaGlow DuraLine Tape is the only floor marking tape on the market to have recognised accreditations for both photolum-inescence and anti-slip properties making it an obvious choice if you need a tape that is tough, hard wearing and highly visible.”

Surfing the crest

Another key supplier in this sector is the aptly named Dorotape, which is headed up by well-known personality James Carpenter. He explains that to understand the current direction of development for adhesive technology, you have to look back across its history: “The sign and graphics industry has been continually developing over the years and the requirement for adhesive tapes has evolved to meet that challenge.

Dorotape’s James Carpenter explains that specifying the right tape for the job is critical. (Pictured) Dorotape’s colourful stand at Sign and Digital UK 2014 showcased the company’s wide range of products, a key strength for the firm is it has hands on experience with how adhesive technology effects different types of sign-making materials

“The use of double-sided tapes can save time in production and fitting; act as a weather proof seal and even as a flexible join between two substrates. We have responded to this demand by adopting technology changes to meet particular requirements for a tape to do a particular job. In many cases there is already a tape available that will fit the bill. However if this is not the case then it is up to the manufacturers to bring one into production assuming the quantities are there.”

In terms of products, Dorotape offers a broad range. Carpenter adds: “It is always important to decide on the correct double-sided tape for the task in hand and it is particularly important to get the advice of the supplier. We supply a straightforward range of tapes to fit most requirements within the industry.”

Some of its flagship systems include Doro-Fix 465, a versatile, all-rounder that is Dorotape’s bestselling tape. With its thin PE carrier and solvent acrylic adhesive it can be used outside where a flush finish is required. It is also plasticiser resistant and Carpenter says it makes a very good banner hemming tape, while DoroBond 894/

895 are pure acrylic ultra-bond tapes for tougher projects. Applications for these latter tapes include demanding metal sign assembly; bonding powder coated surfaces; vehicle body parts, and even glass lamination. Finally the Doro-Fix 420 is a greater quality universal double-sided tissue tape for interior use. The tape has a high level of tack and will withstand high temp-eratures and is suitable signs, decals, labels, badges, and trophies.

In a market which literally has to stand and fall by the quality of its products, it is essential to check that the product you are looking will fulfil its purpose. Companies that have invested heavily in tried and tested solutions for both tapes and adhesives will offer you the security you need to ensure expensive signage solutions do not get unstuck.

Your text here...