Founded in 1996, Sign Outlet, based in Alsip near Chicago, invested in the technology as it produced a wide range of products for both the retail, hospitality, fast-food, and architectural signage market in the region

When I started trying to research the machinery that is responsible for all the beautiful built-up letters that adorn buildings and businesses across the UK I really was astonished to find that it is an incredibly secretive and difficult sector to penetrate. Call after call met with dead-ends, reticence to talk about machinery specifications and capability, and sometimes pure hostility from sign-makers as to why I was enquiring about their technology. At one point I really thought I must be going round the bend.

Well, after much research and finally having a few good conversations with some key sector players, it emerged that there is very good reason for this wariness. Whereas in the USA there is a well-established trend of medium to large sign-makers investing in automatic letter benders, metal presses, and welding machinery to bring sign-letter fabrication in-house, this is not the case in the UK and Europe. The reason comes down to the evolutionary nature of market forces. The USA obviously has a lot more sign businesses with the capability to invest in machinery that can normally go for north of £40,000. As a result there was enough of a market in the early days for companies such as Computerized Cutters to set themselves up and sell technology into their home market and provide technical support for it.

Finding a reliable supplier, for exactly the right materials, to be used in letter bending machinery can be a challenge, as the market is concentrated in the hands of a very few players in Europe. The result is that your machinery supplier will very often end up being your material supplier too

In the UK however, this just has not happened. Some of the biggest trade supply players in our industry bought into the technology very early on, set themselves up on a truly industrial scale, and simply sold sign letters at prices that were so affordable that it just did not make sense for your average sign-maker to buy an automatic letter bender. The result was that demand was low for such machinery and thus no distributors moved in to try and take advantage of the market on these shores. So, while for our American cousins the price of such technology has steadily become more affordable, and trade suppliers have not dominated the market as a result, the opposite is true here. For your average sign-maker it is very difficult to make the economic argument to bring sign-letter fabrication in-house, as they just cannot achieve the economies of scale necessary in a short enough time span. The result has been that price for built-up lettering has remained very low on the market, as sign-makers buy from trade suppliers and compete in very tight margins.

(Above & below) The TPS-S9700 Automatic Bending Machine and QL-200 laser welder are distributed through Dublin Signs, which has a showroom in Stillorgan, Dublin

Today the choices really are few and far between if you want to bring production in-house, but within the scope of what is available for import, there are some very interesting and fantastically designed pieces of technology. Computerized Cutters sells its Accu Bend brand through Channel Letter Benders in Leiden, the Netherlands. Automatic Letter Benders are also another well-known European name, and export into the UK from its base in Bialystok, Poland. And one of the original industry players that still remains a strong market player is Korean-headquartered SDS, which distributes its systems through Domino Sign in France.

On the home front however it really is a poor show. There is no dedicated manufacturer of such systems on these shores for the sign industry, although there are quite a few bespoke machinery manufacturers that specialise in CNC metal bending products for other industries. There is only one UK-based distributor in the form of Mart Group in Luton and the next nearest to us is Dublin Sign in Ireland. The latter two import these systems, their parts, and materials in from Asia though and act as buying conduits rather than stockists and technical support partners.

True to form

Despite all these swirling issues and trends, there has been a brave few in the UK who have taken the decision to bring production in-house and not joined the trade supply fray. One of these is Benson Signs, headed by Chris Benson, which made the leap in 2005.

“The root of this issue in the UK goes back to when we first bought the machine, and we were only the second company in the UK to buy such machinery and perhaps the eighth in Europe. Think about that compared to the US, where just about every sign shop has some form of automated letter bending and laser welding equipment.

“At the time perhaps there were a few very big companies that got in quick and bought up the technology. Mostly, some of the bigger trade suppliers bought up the technology which enabled them to enhance their offer as trade suppliers. In the UK there is an unwillingness to buy this sort of equipment, they’d rather buy it in if somebody is supplying it. As they can buy this sort of product as a trade item now, it meant they didn’t have to buy the equipment. That’s how the sign industry differs in this country to Europe and the US. Trade buyers do a lot more businesses than in other countries. There are some very reputable trade suppliers, but a few walk a very fine line between selling to the trade and selling direct to end-user.”

Think about that compared to the US, where just about every sign shop has some form of automated letter bending and laser welding equipment”

Benson continues: “The general feel you get if you ring people up to ask advice about this technology will be: ‘Yes we do this, but it’s not something that we would talk about”. This is crucially because having this equipment in house will allow you to improve your productivity and overall profitability in the long-run, but is no easy road. As a result people are very protective over this hard won capability and don’t want their competitors to know anything about it.

(Above & below) Automatic Letter Benders is based in Poland and debuted its machinery to the UK market at Sign and Digital UK 2015. Its systems range from the ALB-01 ECO 130/160 Deluxe for smaller applications, through to its ALB-03 SSA 180 Pls, which can hand tape widths up to 180mm at 2mm thick

“The problem with the British sign industry is that it has changed radically in the past 15 years. Here we are one of the very few retail sign manufacturers that carries out most manufacturing in-house left and deals directly with the end-user. You can probably count the number of companies left on one hand who produce the number and variety of products we do in-house.”

Benson’s point is sound, as many sign-makers today will only have a vinyl cutter, inkjet printer, and router in-house. Indeed, it is now only the trade suppliers that by and large will have spray shops, powder coating, screen printing, metal working, laser cutting, channel letter bending, built up letter fabrication, routing and engraving all under one roof.

“We took a decision to improve our manufacturing capacity in 2005 and that is why we invested in an Accu Bend through Channel Letter Bender in The Netherlands. The investment decision was proved right, but a huge issue is simply logistical distance. This is not a slight against any of the suppliers, but if you want to maintain it, then the fact is you need to have some good electrical engineering skills. If you buy a router, for example, and you have a problem, you can ring the engineer and it is sorted within a few days. If we have a problem with our bending equipment and want it working again very quickly then we have to fix it.”

On the market

Speaking to Benson, who also has a lighter weight letter bending system from SDS, he explains that a key issue to consider when purchasing your technology is its application. Their choice was Accu Bend due to its industrial build quality and reputation globally.

Speaking to Remko Van Gellecum from Channel Letter Bender, he explains the history and thought process behind its design: “Accu Bend from Computerized Cutters was the first machine in the world to notch, flange and bend complete channel letters, and is recognized as the market-leading channel letter bending machine.

“Nothing else comes close. There is a lot of machinery on the market from China that is very cheap, but you get what you pay for. I have heard so many sob-stories from customers who have invested in machinery from China only to have it break down in six months with no way to get technical assistance or even parts without waiting weeks. There is some decent technology from other parts of Asia such as Korea, but again they are just much lighter weight and scaled for very small applications.”

O Factoid: Automatic letter bending technology evolved out of the development of CNC cutting and routing machinery. Until its invention, virtually every sign-maker used bench-tops metal working presses and years of built-up skill to produce built-up letters. O

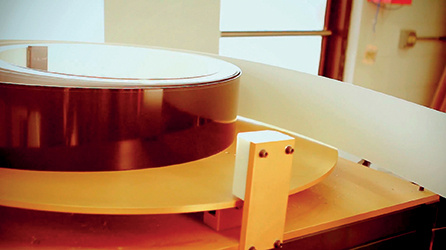

Van Gellecum continues: “World-renowned for its precision and advanced, patented technology, the Accu-Bend machine consists of two main components: a motorized material-feed table, and a bending machine with an integrated swivel computer monitor and stainless steel offload table. Weighing 1,800 pounds, the solid welded steel machine handles .040 to .063 gauge material and can produce single-piece letters, shapes and logos up to 15 feet tall.

(Above & below) Ranging from the Accu Bend Lite/26 to its more industrial-scaled big brother, Computerized CNC has managed to corner the market for machinery in this sector

“Simply import .DXF files, and your channel letters are created. With a dedicated hydraulic power system and dual -motor drive unit, Accu-Bend can also feed up to 12 per second. When it’s time to switch to a new project, coil heights can be changed in under a minute.”

The system is also designed to save labour costs with the optional ‘Robotic Auto Pilot’, which allows the machine to run multiple letters, unmanned. When the system completes a letter, it pulls it from the machine and automatically starts the next letter. The company even claims that Accu-Bend can, ‘reduce fabrication time by as much as 75 percent’.

Indeed, one of the firm’s major supporters on its home turf is Dan Cobb from Image National in Terrell, Texas. He sums up the key advantage that bringing such technology in-house can bring sign fabricators: “You don't have three people doing it by hand anymore, you just have one. The other three people can be putting the backs on to the returns, wiring the letters getting them ready, thus you can put out more product.”

These words from Cobb perhaps sum up the state of this sector in the UK perfectly. While our friends across the pond have seen the light and now investing in such technology is just a normal part of being a sign-maker, here in the UK we have perhaps been far too reticent to investigate the true potential such kit can offer in terms of labour-saving, cost-efficiencies, and overall profitability in the long-run. So, I really do hope that this time next year when I start researching this currently secretive neck of the sign world it will be a little bit less of ‘going round the bend’ and more of seeing its name ‘up in lights’.

Your text here...