Several sign-makers have found success by tying up with boutique ‘cult fashion’ retailers on the high street to supply short runs of items such as one-off t-shirts

The feeling of choosing and wearing new clothes is a unique one, whether you are a fashion-guru or simply buy clothes as a functional necessity. There is always a bit more of a spring in your step when you head out wearing your new kit, an aura of self-renewal, if but for an instant. This ‘good feeling’ is what many retailers rely on for the bulk of their sales, as the majority of consumers do not buy clothes because they need to, but because they get a kick out of it. There has also been a fundamental shift in how branded clothing is being produced. Instead of it being the sole preserve of massive industrial producers, the continual development of small-scale machinery and materials has given consumers a myriad of new sources to get both bespoke and unique garments and accessories.

The collision of these two factors has been good news for sign-makers, as it has meant a boom in demand for everything from ‘one-off’ t-shirts from individual walk-in customers, through bespoke runs of kit for local sports teams, to supplying boutique high-street shops run by designers that specialise in selling funky ‘one-of-a-kind’ t-shirts. So, with all this opportunity there for the taking, where to get started? That’s if you haven’t already.

Established sign-makers who have already invested in a print-and-cut

machine need only add a good stock of heat transfer vinyls, a heat

press, and some blank apparel and they are ready to start making money

from apparel branding”

“Many people associate apparel branding with screenprinting, and if you have the high-volume orders then this is probably the road to take. However, established sign-makers who have already invested in a print-and-cut machine need only add a good stock of heat transfer vinyls, a heat press, and some blank apparel and they are ready to start making money from apparel branding,” says Michael Ryan, group exhibition manager, Americas, Africa, and Eurasia, FESPA.

He adds: “A good supplier of blank apparel is essential. UK companies like BTC Activewear, Ralawise, and Pencarrie have a great selection of blank apparel available on demand. When sign-makers have everything in place they should then start promoting the service to customers.”

FESPA has a long history in this market sector due to its roots as a pan-European screenprinting association. And a core element of its modern shows that always seem to draw a crowd is the garment or apparel branding demonstrations and stands, where dyed-in-the-wool masters of their trade wield design programs, multiple-heat presses, and transfer material to produce a kaleidoscope of funky designs on everything from beach bags to hoodies. Speaking to Ryan about the potential growth of this market, based on his own experience and FESPA’s research, he is very positive: “The market growth is limitless. At one scale you have high volume 10,000-shirts-a-day textile production for retail fashion and sportswear. On the other you have smaller, local, ethical, individual, and personalised production. This is where I believe there is a very exciting future for many different types of print-service-provider.”

Ryan continues, explaining how the garment printing market is currently taking shape: “I consider the market to be segmented in two ways, high volume (retail) and low volume. Low volume is where the traditional sign-maker should be targeting their attention. I would guess that an average sign-maker or graphic producer works locally, let’s say within a ten mile radius. Think of all those customers who have ordered posters for their stores; families who’ve ordered banners celebrating a birthday; a tour banner for the local rugby team; the plumbing company that ordered five van wraps; the hen party that needed a life-size David Beckham, and the new bar which wanted a custom-made illuminated sign. Imagine the extra revenue generated if they all wanted branded apparel, and you could deliver it.

“So the next time a customer requests a job, sign-makers need to think about how the artwork would look on a t-shirt, a bag, or banner.”

FESPA prides itself on helping to educate visitors on a wide-array of business opportunities. A legacy of its screenprint-dominated past, t-shirt and textile printing demonstrations are a mainstay of the show and are always a visitor favourite

FESPA Digital 2014 is taking place in Munich and is co-located with European Sign Expo. The event is set to provide another strong showcase for the potential of garment printing and decoration as a potential revenue stream. The event incorporates FESPA Fabric, which since 2010 has specifically addressed the opportunities around garment printing and decoration, for fashion and promowear applications.

Ryan concludes: “Plus, many of the digital manufacturers that sign-makers already know and use will have apparel branding solutions on their stands. Once visitors start engaging with exhibitors, and make it clear that this is an area of interest, they can learn about a whole host of creative applications for apparel branding. […] All the latest technologies will be at FESPA Digital 2014 and in Hall A1 there is a dedicated Fabric Hub on the show floor where sign-makers can learn from experts in garment printing and decoration.”

Sign and Digital UK kicking off on April 29th at Birmingham’s NEC will also have a garment printing demonstration zone with a number of key players in this field exhibiting at the show.

The apparel branding market in the UK is worth the best part of £20m and first and foremost I think the move into this sector for a sign-maker is a very, very simple move to make—as long as they follow some very fundamental rules”

While the majority of wide-format print-and-cut digital printers are suitable for moving into doing garment printing, there are only a few who actively promote it as a core area of diversification to their customers. One such player is Mimaki, and its UK and Ireland exclusive distributor Hybrid Services. The company’s sales manager, John de la Roche, explains why: “It is quite an easy leap of faith for the sign-maker’s customer, as if you are already supplying branding to them, whether it be vehicle wrapping or a banner with a corporate message on it, then it is not too difficult to imagine them investing in garments.”

FESPA’s group exhibition manager, Americas, Africa, and Eurasia, Michael Ryan believes that the market growth around apparel branding is almost limitless

De la Roche highlights systems such as the Mimaki CJV30 and its SS21 inks as an ideal choice for both small sign-makers looking to open up a relatively big new product arena for their business, or medium to large sign-makers who want to broaden their current offering: “Chances are if you are a sign-maker who has got digital print capabilities you will already have a big part of the investment, as we are talking about an outdoor durable printer or printer-cutter. The CJV30 has four different sizes; 0.6, 1, 1.3, and 1.6m. The two smaller machines in the spectrum are actually sold to people who are full-time garment decorators, but because it can do the full spectrum of core output for sign-makers, it means that garment printing can be an additional to string to its bow.

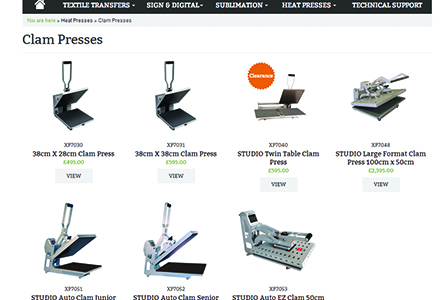

“After your printer all you need is a heat press, and that is a fairly simple piece of equipment and easy to invest in, as even a really good quality one would be under £1,000 from a good supplier such as Xpres.”

Mimaki’s wide-format digital print-and-cut systems are designed to output high-quality graphics onto transfer films that can then be applied to everything from t-shirts to beach bags

Indeed, Xpres has one of the widest ranges of machines and materials in this sector, offering everything from units for specifically branding caps, through nifty swing presses, to pneumatic systems to save operator’s arm-ache on long-runs. De la Roche goes onto advise that investing in the kit is actually the simplest part of moving into garment branding; its selling and marketing the products themselves that needs the most thought, as he explains: “The most obvious route when you are diversifying your product range is talk to your existing customers as you’re already a trusted partner and are doing a great job of their posters, vehicle graphics, or general signage. I bet you that they are already buying branded garments anyway, it is just that they don’t realise they can get it from you directly. You should be sending these regular customers e-mails or direct-mail, perhaps interacting with them via social media, to advise them of your new products.”

This is the crux, as it is one thing to have the skill and creativity to start-up a new revenue stream, and another thing to make it work. De la Roche provides some very good advice that he says has worked well for a number of Hybrid’s customers. He explains that as you will already have their artwork on file, then why not create a range of targeted samples for your top 20 percent of contacts and then send them some free examples followed up by a phone call to ask if they would be interested in buying this service from you in the future, with a discount on their first order. An example would be a sign company that renews all the A-board and menu signs every three months for its local pub asking if it would like a run of branded polo shirts for new staff uniforms. Or doing a one-off run of promotional shirts for the annual beer festival they run, tying in with their normal run of banners to promote it.

Once your operation is established and running to capacity, then scaling up to cater for higher-volume orders is just a matter of investing in quicker machines, perhaps a multiple carousel heat press, and the operators to run them. Looking at efficiency considerations, then one of the most efficient heat press systems are double platens, where while you are pressing one print you are laying the next one up and you can just slide the platen underneath the heating element. This doubles the productivity as it means you can prep on the left and then press on the right, slide the garment across, and then reverse this order with no time-loss.

Fashion conscious: Spandex’ director of sales and marketing, Leon Watson, explains that the company is continuing to invest in and expand both its machine and material range for the creation of products such as t-shirt printing—spurred by increasing demand from sign-makers

De la Roche concludes: “Last year we hosted our Wide-format Wave event, and the most rewarding thing was two customers in particular, one who was a commercial printer and the other a vehicle graphics specialist. They both went away inspired as they just didn’t realise the number of things they could do on their existing equipment, and garment printing was one area that really stood out for them.”

New ideas

So, you have the creativity, the right printer, materials, and the drive, but what about the next step and the true merits of starting up a garment and decorative product printing wing? Your Print Specialists (YPS) director, Gary Brown, has spent a long time educating his customers about the potential of this sector, as he explains: “We have been talking to customers and getting them to open up to new ideas, where they have the kit in place but their knowledge is perhaps not so strong. The key thing for any sign-maker today is to open up as wide a variety of revenue streams as possible where demand is up, but the market is not yet saturated.”

In addition to its arsenal of Canon, Epson, and Mimaki printers, YPS also has a wide range of heat transfer films, both from major players such as Metamark and its own Rainbow brand. This is a new horizon of focus for the supplier, but Brown is confident that it is one that will be fruitful.

Ready sports fans? A huge area of potential for sign-makers is producing branded apparel such as sports kit for local teams. Hybrid Services’ John de la Roche explains that the quality of today’s digital print systems and transfer material means that products can be produced to very stringent standards on both colour matching, durability, and graphics resolution

“Not only is demand growing for areas such as t-shirt printing and general apparel, but also for things like bags and even umbrellas. There are a number of core wide-format brands that sign-makers have that would be able to easily produce graphics for these applications, but often they haven’t even thought about this possibility. That’s why we have setup a demonstration facility where we invite customers to come, bring their files, and we will produce textile-based products for them there and then. We have all they kit they need and will show them each stage, as we also stock the Adkin heat press range.”

Brown goes onto highlight that there are also some key opportunities avail-able in this arena as the number of high-street fashion boutiques multiply across the UK. This trend is a counter culture to corporate retail, as a growing number of teens and twenty some-thing’s tapped into individual fashion cultures no longer want to buy generic designs from your average Top Shop, and are flocking to buy from small outlets that suit their specific tastes and style.

“One of our customers supplies to a young designer in Newcastle who runs a high-end ‘factory shop’ who does really funky t-shirts and ‘on-demand’ designs for his customers. New kit like Mimaki’s SUV is also being used to print onto fauxleather for bespoke designs on things like motorcycle gear. Sometimes it’s as simple as breaking down the barriers, and getting people to realise they don’t need to be a one trick pony, but can very easily use their existing setup to branch into new and niche areas. You already have the expertise and equipment, so with just a little bit of extra investment and removing the blinkers there is a big market out there for everybody

and a steady revenue stream waiting to go.”

O Factoid: Screen printed heat transfers were introduced in the early 1960’s. The original applications were on soft vinyl materials for checkbook covers and eye glass cases O

Safe hands

One of the broadest suppliers to the sign industry, Spandex, is also quick to affirm that it is seeing growth in the garment printing arena, and has reacted accordingly.

“The apparel branding market in the UK is worth the best part of £20m and first and foremost I think the move into this sector for a sign-maker is a very, very simple move to make—as long as they follow some very fundamental rules,” explains Spandex’ director of sales and marketing, Leon Watson.

The Epson SureColor SC-F2000 is the world’s first dedicated garment printer and is capable of outputting every 27 seconds on light colours, and 111 seconds using its white ink onto dark garments

He continues: “You can use the existing printer you have today and there are a wide range of materials that you can buy. But where you have to be very careful, and which is why we are bringing out a comprehensive price and user guide, is to select the right transfer material for the right application. You also really need to follow the right guidelines on heating times and temperatures, whilst also making the customer aware of the washing and ironing instructions.”

This is a key point, as it could mean the difference between a happy repeat customer and one who demands his money back when the graphic peels off after one wash. Flock and flex products are the core materials used for the majority of small-volume applications, and as such Watson highlights that a rapidly-growing technology area are low-cost desktop inkjet systems such as Roland DG’s BN20 that are specifically designed for printing onto such transfer materials.

Xpres specialises in supplying machinery and materials to sign-makers who have diversified

into producing products such as t-shirt printing

Highlighting customer success stories that have gone onto supply printed garments for some major high-street fashion and sports brands with its support and products, Watson also highlights that the most successful sign-makers in this area are those who pro-actively seek out customers. He gives an example of one further Spandex customer who pitched to the VW Car Club to print its wide-array of branded apparel for everything from camper van driving surfers through to hot hatch racing petrol heads.

“If you can win and retain these type of customers, then you will be in a very sustainable position with this type of business. The potential is certainly there, we have recognised it, and the coming months will see us focus our attention on it in a big way. The recent Printwear and Promotion show highlighted to me that this is still very much a cottage industry and what we are trying to build is that we want to make it straightforward, easy, and consistently profitable for smaller sign-makers to offer this service to their customers.”

Your Print Specialist’s director, Gary Brown and financial director, Hazel Watt. The company has reacted to requests from its customer base for solutions that will allow them to service growing consumer demand for everything from stag night t-shirts through to cult fashion

A direct option

A final area of consideration in this area is dedicated direct to finished-garment printing. While there is a number of options in development for the market, the one that has made the most waves and was first out of the gate is the Epson SureColor SC-F2000. Using crack-resistant inks, users can configure the system to suit their needs by choosing from two sets of CMYK ink for white garments or CMYK with up to four white inks for coloured garments. The machine also comes bundled with some clever software dubbed Garment Creator, which includes a cost calculation function, allowing you to estimate the print cost by calculating the amount and cost of the ink used for each print job.

“Unique to this industry, this is the first system where a printhead, ink, and chassis have been designed and manufactured by a single brand. The hardware and ink are designed to work together and users benefit from the reliability and high-quality output that Epson is renowned for. As well as enjoying the new revenue stream, they can be assured that Epson has applied its years of print knowledge and know-how to deliver an ecofriendly device that excels in performance and delivers low running costs,” claims Martin Johns of Epson UK.

Able to print on material up to 25mm thick such as caps, bags, and t-shirts, the machine can do a print every 27 seconds when using dual colour mode, and can print onto a dark coloured substrate in 111 seconds using white and colour ink.

Whatever technology you choose to use for your new garment printing wing, one key trend has been marked out by all the great and good I have talked too. This market is taking off in a big way—but as with any boom area of the sign industry, it will eventually reach something of a saturation point—so get fashionable while the going is good.

A real opportunity to create new business

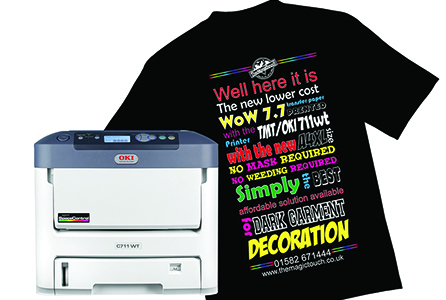

There are various clever solutions available to ease your way into the garment branding sector, including the new WoW7.7 transfer paper from TheMagicTouch.

This new lower priced solution for full colour decoration (including white) on most garments and textiles is compatible with the ‘White Toner’ TMT/Oki 711 and the ‘CMYK’ TMT/Oki 610 printers, offering new paper sizes, no mask, no cutting, no weeding, and easy two-step process.

TheMagicTouch and Oki have part-nered to cater for customer demand

The ‘super-thin’ printed transfer is designed to provide a soft-feel together with bright colours and good durability. Jim Nicol, managing director of TheMagicTouch in the UK, explains: “The WoW7.7 together with the C610 and C711WT printers offers a real opportunity for the user to create new business from existing and future customers across many different products.”

According to TheMagicTouch, WoW7.7 has evolved to fit the new white toner technology, reducing the transfer production to a two-step process using a traditional quality heat press, and allowing a single operator to produce in excess of 40 garments per hour.

“Having the power to produce quality samples quickly is a mark-eting dream. The dream is now reality, with no restrictions,” Nicol concludes.

jhlhlkjkljl