Being able to up-sell products such as corporate gifts to your regular customers, or creating a bespoke smartphone cover printing service, could create some very solid additional revenue streams for your sign business

People have traditionally thought of printing as a 2D process, printing onto paper, vinyl, or other flat substrates. Until relatively recently, printing methods such as pad printing or screen printing were the norm for printing onto 3D objects, but they have always had limitations in terms of the graphic range and compatible substrates, as well as being time intensive with high setup costs. If you wanted to put your logo onto a product, be it a pen, lighter, golf ball, or USB stick, to then give it away at events or to visitors at your company, you had no option but to go down the traditional route. This meant long minimum runs, a limit to the col-ours you could use, and a long lead time.

With the development of UV ink technologies over the past few years, 3D printing can now be achieved on an incredible variety of surfaces, substrates, and materials, opening up new areas of creativity and new revenue streams for those offering this service.

Flatbed LED UV printers, like Mimaki’s UJF Series, provide all the usual digital printing rules and benefits. Mike Lewis, industrial products sales manager at Hybrid Services, comments: “Short-run printing costs the same per unit, whether the run length is one, ten, or 1,000, providing unlimited colours, no setup costs or start up time, and a high-quality print.

“Sign-makers and graphics companies with this sort of hardware can deliver promotional products alongside small-format, direct-to-substrate signage, or even products that fit within a manufacturing workflow, meaning they can become an interesting and profitable revenue stream, utilising the same equipment.”

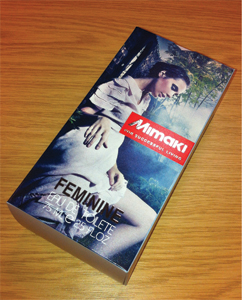

The Mimaki UJF-3042FX has been a pioneering machine for the 3D object printing sector

The ability to deliver short runs of finished, printed products has enabled forward-thinking companies in the promotional items industry to sell a new type of product. Historically limited to large minimum run lengths (to make screen or pad printing viable) and limited colours, printers like the Mimaki UJF Series have created a huge window of opportunity for these companies to benefit from its skillset.

“Short runs used to cost a premium,” continues Lewis, adding: “But the Mimaki UJF Series puts the power is back in the printers’ hands. If customers are demanding a fast turnaround, it provides the capability to achieve it and charge accordingly. The output is higher quality than screen print, can be delivered in short runs at a lower cost and in retail environments. It also matches the idea that practically every aspect of a consumer’s life can be personalised.”

Short runs used to cost a premium,but the Mimaki UJF Series puts the power is back in the printers’ hands”

The market for bespoke domestic decoration continues to grow; social photo sharing networks are creating a market for prints onto substrates more exciting than photo paper. Consumers’ expectations have rocketed in terms of what they can purchase and what they’re prepared to pay.

Lewis continues: “Where technology capped the capability to deliver certain solutions, Mimaki’s digital printers are at the heart of many companies’ ability to offer a beautiful decorative product, to be displayed and cherished for years to come. That’s a unique offering to a modern requirement.”

(Above and Below) Nothing is safe from the addition of digital print. The only limit is imagination

At the other end of the scale, companies can use similar printers to deliver short runs of pens, with each one individually decorated. Why commit to 100 sleeves of golf balls with your logo on when you only want 25, and each of them is to have not only your logo, but the delegates name on. In 2014, that is not too much to ask and it can be turned around, in full photo quality, in a matter of hours.

O Factoid: Watch-making was the first significant application for printing onto 3D objects just after World War II. O

Lewis goes on to say the Mimaki UJF has become one of the ‘de facto’ products in its sector, for a number of reasons. He continues: “Mimaki has a very long heritage in small-format UV printing, launching the first in the early 2000s, and its consistent mix of innovation and high quality of output has led to a strong reputation.

The UJF range of three printers not only features vibrant process inks, but a bright, opaque white to enable clear or coloured substrates to be printed on. A clear lacquer gives a beautiful glossy finish and can protect the print and a unique, jettable primer assists the ink in keying to difficult substrates, placing it only in areas where it’s required. With up to 150mm head gap, a choice of an A3 or A2 format bed and a high-production speed, the UJF is a very attainable and affordable product range.”

An exciting new area for Mimaki is a product called Digi-Foil. Mimaki showed this originally at FESPA in 2012 and it has been further developed by I-Sub Digital using Mimaki’s UJF Series at its heart. DigiFoil allows a traditional foiled effect to be created within a digital technology, which could cut out vast amounts of time and expense in making the hardware to apply the foil. For the packaging, trophy, and high-end personalisation markets, this is a huge breakthrough.

Versatile application

Mimaki’s Digi-Foil has massive potential for

applications and profitability

Another key player in this field is Roland DG, its Academy and Creative Centre manager, Joe Wigzell, explains its outlook: “Cost-effective, easy to use machines like the Roland

VersaUV LEF-20 are revolutionising the promo-tional, gift, industrial

marking, and even signage markets by enabling printers and high-street

stores to bring this work in house and produce short-run items or

one-off designs, maximising profitability in the process.”

Roland DG has been one of those at the forefront of development in this area, as Wigzell explains: “With our VersaUV LEF-20 desktop flatbed printer and our other VersaUV printers, we have a 3D object printing machine suited to most markets and needs. With training available through our Roland Academy and our product-specific Better Business Boot Camps, as well and easy-to-use equipment and software, it is very straightforward and quick to integrate these technologies into a business to aid in expansion and diversification. Quick turnaround times and an incredibly easy to use system mean that the LEF-20 is a product focused on profitability.”

Roland DG’s new larger VersaUV LEF-20 desktop flatbed UV printer

The desktop VersaUV LEF-20 has a print bed size of 508 x 330mm and is able to print objects up to 100mm deep at good speeds. It can print up to 20 iPhone 5 cases in just five minutes in full colour CMYK.

Wigzell adds: “The LEF-20 also makes printing one-off larger items such as signs, laptop covers, photo albums, and even guitar bodies much easier. The maximum object height of 100mm increases the range of printable objects dramatically and with Roland’s instantly drying ECO-UV ink including white and gloss for special effects, users can print directly onto almost any substrate including acrylic, wood, board, metal, plastic, PET, ABS, glass, canvas, and even soft materials like TPU, leather, and fabric.

Ipad cases printed with Roland’s VersaUV LED

“Today the market requires highly customised or personalised items and in short-runs, on demand, and this will only increase over the medium term to the point where it is the expected norm. Consumers are also increasingly aware that digital print is so much more than just flat paper, vinyl, or banner printing, so this in turn will lead to more niche markets and increase the standard of what’s available now. In addition, with margins on larger batch runs getting smaller and smaller, businesses need a technology that enables them to print in-house, quickly, and with minimal set up or labour costs.”

Today the market requires highly customised or personalised items and in

short-runs, on demand, and this will only increase over the medium term

to the point where it is the expected norm”

Another digital printing equipment company with key products in this area is SSE Worldwide. Managing director, Scott Armitage, says: “SSE Worldwide has more than 23 years’ experience in the industry and with our extensive network of contacts we are able to help customers achieve their objectives. Since its foundation in 1990, SSE has expanded to provide a wide range of printing equipment, with showroom demonstration facilities.”

SSE is a distributor for DPI DG PRINTING of Italy for its range of Eagle UV LED digital flatbed printers and also Allen Data graph of the U.S.A for its range of ADSI iTech digital label printing and finishing systems.

Armitage adds: “The market for printing on to 3D objects is a growing one due to the increased interest and requirement for products to be branded or personalised. 3D object printing jobs undertaken by the screen or pad printing process are usually for longer runs with basic block type graphics.

More recently, there has been a growing trend for companies to invest in the new digital UV LED flatbed inkjet equipment themselves as there is a requirement for fast-turnaround, short-run, personalised products with high-quality results. These products can be decorated much quicker, cheaper, and easier than using standard analogue types of printing.”

(Above and Below) The Baby Eagle from SSE provides a 250mm clearance for a broader range of applications

SSE’s experience in supplying equipment in the screen printing market led them to look very carefully at the specialist digital printing equipment, which in turn led them to DPI DG of Italy. Armitage continues: “The range of printers we supply start with the ‘Baby’ Eagle (BE LED), Eagle 40, Eagle 60, and Eagle 100, with print areas from 450 x 600mm up to 1000 x 1500mm. The Eagle 40 up to 100 use the unique wing design, which gives operators excellent accessibility to the print area. It also allows objects up to 250mm high to be placed and removed, even when printing is taking place to increase actual production volumes. The Eagle printers also use a bulk ink feed system, which makes for cheaper ink costs when compared with cartridge type ink delivery,” he concludes.

This very specialist market for 3D object printing is only likely to continue its rapid and exciting growth. The printers from several suppliers continue to increase in quality and versatility and are opening up new and profitable business channels for printers and sign-makers alike. As long as there are imaginative ideas for things that can be printed on that are accessible and affordable, this is a market well worth considering.

llllllll%S