Off the page

The world of 3D print is currently exploding. It is infiltrating multiple industries from the engineering, automotive and of course, advertising and marketing sectors to healthcare.

But just because 3D print is being utilised in these areas, is it actually a viable pathway for print-service-providers? Will investing in this technology open up doors to this world of opportunity?

The answer is yes. There will be opportunities opening up in architecture, engineering and prototyping, not even to mention in marketing and signage. Companies will be able to get involved with small-scale models all the way through to large-scale production if you are willing to invest in the right equipment.

3D print has been used to create housing projects in developing countries, with New Story, a non-profit housing organisation and ICON. The San Francisco-based company designs 3D printers and helped New Story to create these homes. One house can be built in less than 24 hours and costs just over £3,000.

Elsewhere in space, and 3D printing has even been utilised by NASA. It awarded a contract to Made in Space, which was a £58.8m project to research if 3D printing can be used to manufacture spacecraft components in low-Earth orbit.

SignLink has also covered numerous wonderful stories on how 3D printing has allowed for new limbs for young children, and even new organs. Last year, Global Data initiated a study to find out more about 3D print in healthcare, and found that scientists had presented a 3D bioprinter that could even produce fully functioning human skin.

The exploration of new technology in this area is high on the agenda for some. Finnish company UPM has launched GrowDex T, which is a new hydrogel to help researchers visualise cells in 3D. This gel utilises Finnish birch in a sustainable way – another topic high on many businesses’ lists. It can be used in 3D cell culture (spheroid and organoid formation) drug release studies and 3D bioprinting. Dr Akihiro Matsuoka and his team at the Northwestern University Feinberg School of Medicine presented the idea of regenerative medicine using this technology in Los Angeles in June this year.

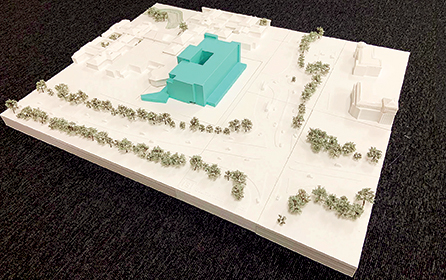

In arguably less incredible circumstances, architects, engineers and technology buffs benefit from the use of 3D printing. IBI Group, which operates in all of these areas, has recently found that its own architects were thriving through the use of 3D print.

IBI Group, which is a Canadian company, specialises in many areas including architecture and engineering. It utilises 3D print to show customers models of plans and designs

Studio Associate Carla Queiroz, based in the London offices of IBI Group, comments: “New materials are transforming the possibilities open to us within the architectural arena; while the latest technologies have changed the way we visualise and demonstrate those possibilities to clients.

The company is based in Canada, but have offices in London, Manchester, Brighton and Glasgow in the UK, as well as offices across the globe. Queiroz continues: “All the offices are in touch with each other, sharing expertise and experience – we also share access to 3D modelling. Manchester and London both have 3D printers that we use to create models of potential projects. The other UK offices also use them. They are very popular, to the point that we had to design strict protocols and establish time scales for delivery.”

O Factoid: A Ricoh study found that 68% of healthcare professionals believe that 3D print technologies have the power to transform the way they will provide healthcare. O

The IBI Group offices utilise a MakerBot Z18 fused deposition modelling printer, which has a build volume of 6474.46 cm3.

Even the University of West of England (UWE) has taken to 3D printing, creating a lab and a print research centre. It is so readily accessible with software available and different materials no longer reserved for high-end engineering firms.

But even with all the amazing things that 3D printing has allowed all of these sectors to achieve, is there a real revenue stream for commercial printers and sign-makers?

Manufacturer’s view

HP demonstrated its 3D prowess on the Diversification Zone at The Print Show 2019 in September, talking to customers and explaining the possibilities when it comes to 3D printing.

HP were on the Diversification Zone this year at The Print Show at the NEC in Birmingham

Anne Sharp, who this year swapped to head up the 3D print division and is now the HP UK & Ireland and Nordics 3D marketing manager, explains that HP technology can help with small-scale production through to larger scale production. She explains: “Customers can start with equipment more geared towards prototyping and small-scale production, like the HP 3D Jet Fusion 500/300 Series. With demand, companies can build to offerings that are optimised for larger scale additive manufacturing, like the HP 3D Jet Fusion 4200 and HP 3D Jet Fusion 5200 Series.”

HP’s Jet Fusion 3D 4200 Printer

Sharp adds: “HP is unique in the depth of our installation, training and market-leading application expertise. Called the HP Ramp Up Service, we work hands-on onsite with new or expanding HP Jet Fusion customers to prepare teams to get the most efficient and effective 3D parts production, tailored to each specific application. We also offer next business day onsite support and next business day spare parts availability, thanks to our global reach.”

HP’s Jet Fusion technology could help sign-makers enter the 3D world

But even with all of this in mind, are there opportunities for printers and sign-makers in 3D printing to take advantage of? Sharp says: “Unequivocally yes. The growth in 3D printing is underpinned by a fundamental shift in how companies and, indeed, individuals tinker, prototype and enter full-scale production. There’s huge scope for traditional printing companies to expand their service offering and begin to market themselves as Service Bureaus. The investment decision can help print-service-providers to differentiate themselves and keep up with the rapidly growing wider print industry, driving profit margins in a competitive market.”

Sharp also says that there are more specific areas that print-service-providers can consider – one of which is the aforementioned architecture. She comments: “Traditional print companies will find that the same customers for whom they print banners, brochures or labels, are also regularly refining and innovating around finished goods and component parts. 3D printing allows those customers the ability to innovate and refine under the roof of ‘traditional print companies’. This work can take place close to home at significantly lower cost and, depending on the level of 3D print capability, potentially move to full-scale production whilst bypassing complex and high-cost international supply chains.

“A couple of real business examples for print-service-providers to consider 3D printing include retail and architecture,” continues Sharp. “Where print-service-providers are often creating banners, media materials and more to support customers’ product launches, adding 3D printing capabilities also allows PSPs to be agile enough for one-offs or small-run point-of-sale and prototypes for testing new products. On the architecture, engineering and construction side of the graphics industry, investment in 3D printing can give PSPs the ability to create architecture models, or 3D topographic maps.”

How?

But what do you need to consider if you want to move into this type of work? Sharp says that companies would be adding a completely new capability and should make sure that they have the structure and the demand for it. Sharp comments: “With 3D printing, companies are adding a new capability. Speak to customers, understand how offerings will be monetised in a specific market. Of course, HP has dedicated representatives that can help with this process. HP Financial Services can help create custom roadmaps to support each customers’ path to growth, profitability and competitiveness.”

The growth in 3D printing is underpinned by a fundamental shift in how companies and, indeed, individuals tinker, prototype and enter full-scale production”

After a brief foray into the three-dimensional world, could this be the new service that you were looking for in 2020?

Your text here...