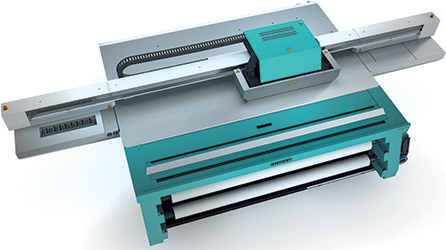

Green power with the Acuity LED 40

Fujifilm has had significant success with its inkjet printers

covering ever growing sectors of the print market. It does this in two

main ways; it not only has a wide range of equipment, but it also very

cleverly makes each piece of equipment overlap the aforementioned market

sectors. By doing this, Fujifilm leaves very little gaps that cannot be

encompassed by at least one product from its stable.

Fujifilm received many plaudits with the Acuity Select 20 and this

manufacturer is becoming accepted experts in the field of LED curing.

Following up this success they recently released the Acuity LED 40

flat-bed printer, the latest since the introduction of these printers in

2007.

So what does this new machine do over its predecessor? As with all

Japanese manufacturers, Fujifilm builds on what it knows works, and via

Kaizen (improvement) production process, it has come to market with a

press it claims reduces costs through longer lamp life and reduced

energy requirements.

At the heart of the machine is a large bed that can take a rigid

sheet with a size of 1.25 × 2.50m, the design ensures edge-to-edge print

reproduction of either one or multiple sheets and this can be

accomplished even on multiple print passes. The table design is

significant enough to provide this high level of print quality on a

maximum substrate weight of 38 kgs and over 50mm in height; clearly

significant.

Should your production needs be even greater, the Fujifilm Acuity

LED 40 comes with two options, one to double the rigid sheet size of

3.08 x 2.5m (known as the X2) and a second is a roll media option allows

for a 50kg substrate weight.

The LED 40 is capable of printing virtually any product, display or point-of-sale signs due to its borderless printing, inks and varnish

To ensure either the heaviest or lightest of substrates are held

securely on the table, Fujifilm has designed a number of dedicated

vacuum zones. They are obviously designed to match up with standard

material size that means the masking of unneeded sectors is reduced, but

equally you are able to change the strength of the vacuum to cope with

different stock weight and size.

Whilst the Acuity LED 40 is designed to cope with one-off

production, it is equally as happy reproducing print copy time after

time. Ensuring each copy looks the same as the next, Fujifilm has

designed a series of register pins that locate the sheets in exactly the

same position time after time.

Added into the X2 version of this machine is the ability to not

only print the double sized sheet as mentioned, but the inclusion of the

register pins on this option will allow for one sheet to be printed

whilst the other side of the machine can used to prepare the next sheet

meaning you can have totally uninterrupted production.

Considering all the various material options, the Acuity LED 40 is capable of production levels up to 52.8sq m/h in high key print mode”

Considering all the various material options, the Acuity LED 40 is

capable of production levels up to 52.8sq m/h in high key print mode and

at a significant speed for even the most demanding of print quality.

Pump up the volume

To achieve this volume of print, the inks and application of them

is quite conventional as far as Fujifilm is concerned. The printer uses

LED UV cured inks that have been especially developed to allow for the

vibrant colours needed with the pin point quality that Fujifilm claim

you can print everything from outdoor signage to fine art photographic

work with light inks.

Fujifilm calls these inks Uvijet KL LED UV and come in the standard

CMYK process colours along with light cyan and magenta, white and a

clear varnish. Depending on the option you take, four, six or eight

channel, the combination of whites, lights and varnish can be adapted to

suit the production you are planning.

All these inks can be deployed at six to 42 pico-litre volumes via a

Piezoelectric drop-on-demand inkjet head. UV inks used to be

problematic, harmful and uncomfortable to use, needing air circulation

systems to remove odour and Ozone from the printing environment.

Nowadays, the chemistry that underpins the inks has moved on

considerably and the Uvijet KL LED UV inks have the internationally

renowned GREENGUARD standard.

GREENGUARD certification is part of UL Environments ecological

compliance program. UL Environment is part of Underwriters Laboratories

(UL) and acquired GREENGUARD in 2011 which provides purchasers with

assurances the products being supplied will comply with the highest of

ecological standards.

To satisfy the GREENGUARD gold standard, the inks supplied by

Fujifilm must meet the stringent emissions standards based on

established chemical exposure criteria. Specifically the Uvijet KL inks

meet the UL2818 standard which is for low chemical emissions for indoor

production.

As you would expect from one of the leading inkjet printer manufacturers, the inkjet head itself comes with automatic nozzle maintenance and ink distribution that will

ensure the quality of the output from the Acuity LED 40 is at the

highest level at all times.

Even cleaning is easy – the printer comes with what Fujifilm call

Automatic Maintenance System (AMS) which means not only hands free

cleaning, it ensures the Acuity LED 40 produces up to 1,200dpi

resolution time after time.

Green print

The green credentials of the Acuity LED 40 run deeper than just the

inks used. One of the leading USPs for the printer is the energy

consumption and lamp life. Fujifilm has reengineered the Acuity LED 40

meaning that it uses 30% power of that of the Acuity Select 20, which

given the cost of energy, makes a significant downsizing of utility

bills.

Fujifilm has reengineered the Acuity LED 40 meaning that it uses 30% power of that of the Acuity Select 20”

Reducing power is not the only way to save on operating costs, the

new lamps used in the Acuity LED 40 are claimed to be able to be

operational for up to 10,000 hours.

The scope of production capable on this printer is vast; the Acuity LED

40 is capable of printing on PVC, polycarbonate, polystyrene, acrylic,

paper, board, wood and even aluminium composites amongst other

materials.

With borderless printing, the combination of inks and varnish and the

variety of substrates, the Acuity LED 40 is capable of printing

virtually any product, display or point-of-sale production for far or

near viewing.