The versatility of Blackman and White’s Versa Tech 2 is provided by its wide range of available tools, including a driven rotary cutter, tangential drag knife, and oscillating knife

With the extensive range of materials now used in sign-making, it is inevitable that many processes that were once carried out by hand have become the task of automated machines. None more so than in the area of print finishing where precision cutting is essential to achieving a high quality product.

This requirement has naturally seen the development of a wide range of digital cutters, with some very sophisticated equipment now on the market, and the flatbed option becoming increasingly favoured. By way of an overview, I have looked at the latest offerings from some of the key players in this sector.

At the cutting edge

Graphtec GB has two new offerings, the FCX2000 cutting plotter and the i-Mark automatic flatbed digital die-cutter.

The FCX2000 cutting plotter from Graphtec GB incorporates new design features to increase performance

Among the latest developments added to Graphtec GB’s range of flatbed digital cutters is the FCX2000 cutting plotter. Complementing the smaller-format FC4500 series of flatbed machines, the FCX2000 incorporates a number of new design features to increase performance and to accommodate a much wider range of materials used in signage and graphics applications.

Its specially configured cutting head incorporates two tool holders to provide a combined cutting, creasing, and drafting function. There is also a USB port to allow offline operation of the cutter and the storage of files that can be retrieved remotely as well as a function that enables a printed barcode and the relevant cutting data to be recalled from memory and cut.

The FCX2000 also incorporates Graphtec’s latest ARMS 6 (Advanced Registration Mark Sensing) system, the recently launched Graphtec Pro Studio design and production software and a wide range of cutting tool options to accommodate different applications. The machine is also capable of processing a wide range of rigid, semi-rigid, and flexible substrates. This includes self-adhesive marking films for window graphics and vehicle wrapping, higher-density reflective films used in the manufacture of road and traffic signs, and heavier board materials for point-of-sale display and packaging applications.

Available in three sizes to accommodate different applications, the FCX2000 offers a choice of either a vacuum suction or electrostatic material hold-down facility, with the former being more suited to the processing of heavier and thicker materials and the latter more appropriate for the handling of lighter-weight media. The cutting plotters have a maximum cutting force of 9.8N (1Kgf) and a maximum cutting speed of 400mm/sec.

Providing a lower-cost alternative to small-format flatbed cutters is the latest i-Mark automatic flatbed digital die-cutter. Based on the popular Graphtec CE6000-40 cutting plotter and incorporating complementary i-Mark hardware and software, it can be used for a wide range of print-and-cut applications. These include primarily short-run label printing, digital prints, and packaging.

The latest i-Mark automatic flatbed digital die-cutter from Graphtec GB offers a lower-cost alternative to small-format flatbed cutters

A key benefit of the i-Mark cutter, and one which Graphtec GB considers sets it apart from other similarly positioned flatbed cutters, is that the cutting process is carried out automatically, thereby eliminating the need for owners to purchase expensive dies. The machine will process both thin materials, such as adhesive sheets and thicker materials up to 300gsm, with the average cutting speed for each sheet being 30 to 40 seconds.

“Perhaps the single most important benefit that sign and graphics manufacturers can derive from ownership of a cutting plotter is that, with only a minimal additional capital investment, they can increase the profitability of their businesses by venturing into new markets,” comments Graphtec GB director, Phil Kneale. He adds: “These include the potentially lucrative print wear and promotional products, labelling, digital printing, and packaging sectors.”

The latest offering from AG/CAD, the Cheshire-based supplier of digital cutting equipment and manufacturer of Kasemake packaging design CAD software, is the DYSS X7 digital cutter.

The DYSS X7 offers precision high speed cutting of materials up to 3.2m wide, with jobs that are longer than the table being accommodated by the machine’s automatic roll and feed conveyor system. In addition, the Touch-N-Go! Easy tool levelling system enables all tools to automatically calibrate height offset.

A clear demonstration of the roll-feed capability of the DYSS X7 from AG/CAD; jobs that are longer than the table are accommodated by the machine’s automatic roll and feed conveyor system

To ensure the DYSS X7-3220C efficiently processes rolls with speed and precision, the gantry of the cutting table incorporates a series of equally spaced suction cups that clamp the bed and the respective substrate and move the roll in sequence with the machine bed. To retain perfect precision to within a tolerance of close to 1mm on lengthy banners, the DYSS X7 utilises the K-CUT Vision Pro System on the cutting head to locate printed reference points along the roll and then re-calibrate the cutting path in accordance with the marks.

One company currently enjoying the benefits of a DYSS X7 is Graphic Print and Sign (GPS) in Newcastle. When owner Malcolm Cairns was faced with the prospect of redundancy from his managerial position at a print company, he took the initiative and set up a print business from his garage with nothing more than a printer, a laminator, and guillotine. Six years on GPS has found its niche as one of the UK’s few print specialists that can offer grand-format as well as standard print and finishing services.

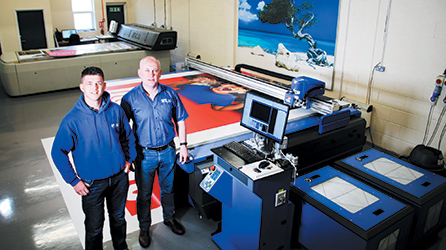

(L to R) Jonathan and Malcolm Cairns of Graphic Print and Sign invested in a DYSS X7 from AG/CAD, which utilises the K-CUT Vision Pro System on the cutting head to locate printed reference points

The company has progressively invested in roll-to-roll inkjet and flatbed UV printers to deliver growth, but its biggest step was the recent acquisition of a Mimaki 3.2m roll-to-roll UV printer and a complementing 3.2m wide DYSS X7-3220C digital cutter from AG/CAD.

“The majority of our work is for design and advertising agencies, sign-makers, litho printers and large format print companies that don’t have 3.2m wide capacity,” explains Cairns. He adds: “The Mimaki UJV55-320 and the DYSS X7-3220C Super Head have already resulted in grand-format work growing rapidly to account for 20 percent of our business. In addition, our subcontract costs have fallen and we are continually winning new customers.”

Production director Jonathan Cairns adds: “From an efficiency perspective, our trio of Mimaki’s would run vinyl and banner rolls overnight, but in the morning we could have a full day of hand cutting. Keeping pace with demand and the printers was proving increasingly difficult. For example, a 50m roll of vinyl would take around four hours to hand cut. It’s now done on the DYSS in 20 minutes. So now, we arrive in the morning and the DYSS will get on and cut printed rolls and banners in a fraction of the time.”

A 50m roll of vinyl would take around four hours to hand cut; it’s now done on the DYSS in 20 minutes”

Specialist UK manufacturer Blackman and White says that its ground-breaking Versa Tech 2 offers unprecedented flexibility and a full return-on-investment in as little as four to six months, making it the perfect choice for both production efficiency and quality standards.

The machine itself won 2016 SGIA Product of the Year Award for Finishing-Routers/Cutters, and was developed together with leading US print finishing solutions provider MCT digital.

Blackman and White’s Versa Tech 2 all-in-one finishing system won 2016 SGIA Product of the Year Award for Finishing-Routers/Cutters

Versa Tech 2’s flexibility is provided by its wide range of available tools, including a driven rotary cutter, tangential drag knife, oscillating knife, kiss-cutting tool, pen plotting, angle-V cutting, crease tool, 100w CO2 laser, and a 5kw water-cooled router. In addition, a strengthened beam and improved rack and pinion drive system give an acceleration capability of 1.25g and speeds of 2,000mm.

Managing director Alex White says: “The Versa Tech 2 is a unique all-in-one finishing system that’s specifically tailored for signage and display, and also addresses finishing needs in the exciting growth area of soft signage and textiles. It offers eight to twelve times the throughput and productivity compared to manual hot knife cutting of textiles, and the laser sealing of cut edges reduces costs on additional finishing.

“It can also handle more intricate patterns than any other router or knife, and its tighter job nesting reduces waste, directly improving bottom lines.”

He continues: “In a busy production environment the speed and accuracy of the Versa Tech 2 when using the laser also allows it to keep up with multiple printers, avoiding a bottleneck that impacts on those crucial lead times.

“We expect customers to be able to get full ROI in under a year or even as little as four to six months for companies running multiple shifts—making it an exciting investment for sign-makers of any size that want to impress their customers with improved quality, cost and efficiency.”

A combined effort

Most companies looking to invest in a digital cutter will be doing so because they have an eye on the future and need to be ready and managing director, Julian Sage, believes that Complete CNC Solutions can offer such companies a digital cutter that is ready for anything.

Complete CNC Solutions’ answer to the need in print-centric businesses for advanced print finishing capabilities comes in the shape of the Protek Unico TT. The company claims that, whilst bristling with features supporting print production, this machine also throws a knockout punch because the very same system is also an unapologetic production router.

AXYZ International’s Trident routing/cutting flatbed machine features a triple-head configuration combining a 10Hp routing spindle with tangential and oscillating knife-cutting units

The Unico TT introduces the possibility of printing direct to materials that lighter digital cutters would not be able to cut.

“That in itself infers a measure of relative exclusivity in the output it can generate,” says Sage, who adds: “In dealing productively with heavy materials, the system is capable of handling the biggest production routing workloads too. For such a big system the Unico TT can deal with lighter printed materials with incredible finesse.”

It knife cuts, it creases, and incises V grooves, and it has static and oscillating tangentially steered abilities, all backed up with precision registration management thanks to an integrated camera. The system even keeps an eye on the inevitable wandering thickness of the material it works with to ensure the right depth of cut.

Although the Unico TT has all the hallmarks of a powerful router, it is both clean and quiet too, as Sage explains: “The Unico TT is comfortable in light production environments, despite being built for dealing with the biggest workloads. It’s quiet, it’s clean and incredibly fast and precise. No matter what work shows up at the door, it gets turned around not turned away when there’s a Unico TT on the shop floor.

“As befits the needs of print production business the Unico TT has resolved the bed issue too. Router beds in the accepted sense are not the best homes for print, but the Unico TT is so clean that the bed can handle anything. There’s even a conveyor version. Future-proof? It just might be. It can grow with the business and handle anything.”

The Protek Unico TT from Complete CNC Solutions introduces the possibility of printing direct to materials that lighter digital cutters would not be able to cut

With sign manufacturers now venturing into new markets such as packaging and print finishing, AXYZ International has responded to market demand with its latest development, the hybrid AXYZ Trident combined routing and cutting solution for print finishing applications.

“Companies are being asked to process a much wider range of materials that invariably require wider, longer, and deeper processing capabilities,” points out Robert Marshall, vice president (market development) at AXYZ. He adds: “The AXYZ Trident is arguably the most innovative and versatile integrated CNC routing and cutting solution currently available.”

Companies are being asked to process a much wider range of materials that invariably require wider, longer, and deeper processing capabilities”

Due to its triple-head machining configuration, combining a 10Hp routing spindle with tangential and oscillating knife-cutting units, coupled with an extremely robust solid steel frame for more arduous processing requirements, the AXYZ Trident will accommodate virtually any rigid, semi-rigid or flexible sign-making material up to a depth of 100mm. Typically, these include aluminium and other non-ferrous metals, aluminium composites (ACM), acrylic and plastic and their derivatives, foamed and corrugated board, vinyl, cardboard, and paper.

The AXYZ Trident can be configured to accommodate any processing area, but is supplied as standard in sizes ranging from 1,524 x 1,219mm up to 2,159 x 3,048mm. Key design features include an exclusive live vacuum deck for optimum material hold-down efficiency, an integrated helical rack and pinion drive system for enhanced routing/cutting precision, more even distribution of the workload and a longer than normal machine life, and servomotors to enable a higher than average level of performance.

Some of the extensive range of accessories that come with the Protek Unico TT from Complete CNC Solutions

Optional machine enhancements include a radically expanded Automatic Tool Change (ATC) facility for multiple job processing and the AXYZ Vision System (AVS) for precise material alignment and 100 percent routing/cutting accuracy.

Since the installation of an AXYZ Trident 6010 machine at Hampshire-based Key2 Group, which specialises in plastics fabrication, signage, and large-format digital printing solutions, the company has seen a dramatic increase in output and speed of production.

Since installing a Trident 6020 combined routing/cutting flatbed machine from AXYZ International, Key 2 Group has seen a dramatic increase in output and speed of production

Key2 Group managing director, Mike Keating, comments: “We chose the AXYZ Trident because, by comparison with other machines on the market, we found it to be faster, cleaner, and quieter as well as being able to process a much wider range of both rigid and flexible materials. It has also enabled us to venture into new markets, and in particular the packaging sector.”

O Factoid: The world’s first programable electronic digital computer was Colossus, which was developed by Alan Turing and a team of engineers. It was used for code breaking during WWII. This revolutionary technology was the root for the explosion of computer numerically controlled systems that run flatbed cutters. O

Of course, there are many more options out there but, even from this brief overview, I am sure you will have gleaned that, depending on budget and whether you require a dedicated cutter or something with dual functionality in order to make provision for future growth, there is something to suit sign-makers and print-service -providers of all sizes.

Your text here...