Inking Space

It does not seem so very long ago that solvent inks were the somewhat unwanted and bullyish new neighbours that moved into the wide-format arena and rather lowered the tone. Now they are everywhere, maybe not as aggressive and smelly as they used to be, but just as tough and perhaps even a bit more lovable.

As a result, for many ink manufacturers, the dilemma remains. Solvent inks make up a huge percentage of volume sales and they cannot simply walk away from it. But they would like some of the more desirable ink systems to move in and clean up after themselves a bit more.

Without wishing to overplay this metaphor, the issue of profitability over popularity is very important to the industry.

“By far our most popular ink is the SS21 low solvent, which forms the majority of the outdoor durable output that customers produce using our printers,” says Duncan Jefferies, marketing manager for Hybrid Services, Mimaki’s UK and Ireland distributor.

Mimaki’s JV33 printers and CJV30 printer/cutters—both of which Hybrid sell in high volumes—come with a choice of ink between the SS21 and the ES3 eco solvent.

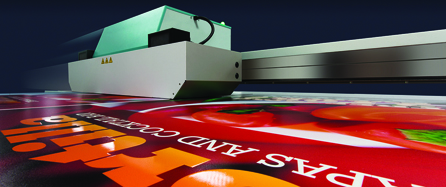

(Above and below) Mimaki claims its solvent ink formulations are still the most popular

medium for bringing the biggest and most daring outdoor graphics to life

Jefferies adds: “But 99 percent of our customers choose the SS21 due to the benefits of better colour gamut, longer outdoor life, and the ability to print to more materials and quicker drying. It makes it a much more compelling proposition than the eco-solvent option.

“SS21’s success is simply that it is an exceptionally high quality and reliable ink that complements Mimaki’s printer range perfectly.”

Hybrid claims that, for the vast majority of installs, there is no need for customers to invest in an air purifier because of the very low odour.

“We also offer customers access to our rebate linked recycling scheme, enabling them to make considerable savings on their ink costs, while we help them manage their print waste responsibly,” says Jefferies.

However, like many other ink manufacturers, while solvent currently remains king in the popularity stakes, new formulations are coming through and are able to offer more in terms of production speed, range of materials and the environment.

For many sign-makers, there are additional jobs that can be produced with alternative inks such as UV, latex, our new SUV inks or dye sublimation to achieve different results”

Jefferies adds: “The Mimaki outdoor durable inks include white and metallic options. However, for many sign-makers, there are additional jobs that can be produced with alternative inks such as UV, latex, our new SUV inks or dye sublimation to achieve different results. As the new machines that support these inks become more popular, so will the ink sets themselves, shifting the balance away from the solvent domination.”

Each ink set has its own strengths. Latex combines strong eco credentials with a broad range of materials. Dye sublimation is the best way to produce soft signage and Mimaki’s forthcoming SUV inks will deliver a unique, hard-wearing glossy finish. Stuart Cole, general manager of Graphic Printing Technologies, has seen the new SUV inks in action in the Mimaki JV-400 SUV printer.

He says: “From what we have seen so far, the printer could be truly revolutionary. It ensures printed media is ready to be used, processed or laminated right after the print. With no degassing required after printing, the SUV ink set will dramatically improve work efficiency.”

Finger on the pulse

When it comes to inks, it seems manufacturers are keen to keep a close eye on what customers are using. Rob Goleniowski, business manager for sign and graphics at Roland DG UK, agrees: “Roland is a development-focused and progressive company. Machines will come and go and inks will go with them, but having the right inks in combination with hardware is the key to going forward. We do not see solvent or eco-solvent going away because there are too many people that love it and want to continue to use it, particularly because they enjoy flexibility, ease-of-use and stunning quality of graphics.”

Roland DG’s flagship ink is the Eco-Sol Max family containing two variations. This series has been on the market for more than seven years and is used by the majority of Roland customers.

The latest Eco-Sol Max2 ink was launched last year, and has been designed specifically for use with the new SolJet Pro 4 XR-640 printer/cutter. Available in 220 and 440ml ‘clean hands’ cartridges, Goleniowski says the Eco-Sol Max family of inks are easy to handle and store, and do not carry an expiration date.

Roland DG’s Eco-Sol Max inks are formulated to ensure they are scratch resistant and

durable on both outdoor and indoor graphics. Available in eight colours, including white

and metallic, Eco-Sol Max inks can be used on a wide range of substrates, with fast dying

times—aiding creativity and productivity

Goleniowski adds: “The inks offer great durability for both outdoor and indoor graphics, are scratch resistant, three-year outdoor light stable and do not require any specialist ventilation plus many other benefits. It simply ticks all the boxes.”

In addition to the standard CMYK ink sets, Roland DG also offers white, metallic and light black inks. These work well with their machines and provide good opacity for window and clear film applications and greater flexibility for customised point-of-sale printing.

“Of course people will look at alternatives, such as UV and other inks that come along, and it is important that Roland gives people more options, says Goleniowski, adding: “Most of it comes down to the required applications. While UV has the advantage of enabling printing direct to rigid substrates, there are still plenty of areas where eco-solvent ink is best. It is about understanding what the client wants.”

Just keep printing

Global ink manufacturer, Fujifilm, has a simple approach to the market. Tudor Morgan, marketing manager for high end products at Fujifilm, explains: “Currently, Fujifilm’s ink volumes are split 50:50 between solvent-based and UV curing. The solvent-based market whilst mature is still very attractive for printers and suppliers alike. Inks are relatively cheap compared to other chemistry types and are very robust. These inks work well with the most popular materials providing very good adhesion, excellent colour saturation and covers a range of applications such as vehicle wraps, short-run posters and banners.”

However, some of its strengths can also be weaknesses in terms of this chemistry not being suitable for decorating rigid media, higher levels of maintenance and limited productivity. Consequently, printers are investing in newer ink technologies.

According to Fujifilm, UV printing is set to take over solvent’s leadership position for

high-end production printing. Latex could be the winner for smaller format 40-60” printers

According to Morgan, sign-makers wishing to go faster need to look at alternative ink technologies, particularly UV: “If you look at the research and development budgets of ink manufacturers, I am sure the majority will be spent on UV chemistry. This is because UV curing ink systems dry instantly, which gives printers the chance for greater productivity and more stability.”

UV platform development has tended to be for high-end production machines, designed for producing rigid and superwide flexible media for high volume customers looking to invest away from traditional solvent-based technology.

All about ink

Alternative or third-party ink manufacturers have also been making great stride forwards during the past year, introducing new ink sets backed by solid guarantees to the market. Perhaps the biggest step forward for some brands is that new colour profiles are not required in order to obtain the same colour as original equipment manufactured (OEM) inks when printing.

Solvent inks are still Mimaki’s most popular formulation for a range of applications,

including these window graphics

The result of this evolution has meant more choice on the market that can be trusted. However, it must be said that guarantee contracts are only as good as the company that honours them and that maintenance and repair is normally restricted to print heads alone.

An OEM guarantee is obviously invalidated if alternative inks are used, and so the cost/benefit analysis of losing your manufacturers obligation to repair faulty equipment if something other than a print head fails should be made before switching.

Regardless of what manufacturers want, like so much in business, the customer is king. Sign-makers up and down the country continue to enjoy printing on their solvent machines for all the reasons quoted above. Whether 2013 is the year this domination is broken remains to be seen, but if you are looking to purchase a new printer, are you looking at more than just solvent? If not, you probably should be.

gggg