Best of both worlds

We’ve explored a great deal of wide-format technologies so far in this series and one of the main themes running throughout is the determination and drive by manufacturers to continue to improve their solutions.

One of the key focus areas in wide-format research and development in recent years has been hybrid technologies, with a number of manufacturers looking at how they can offer users a more affordable entry point to the market without having to compromise on output quality.

Here, we speak with some of the manufacturers making significant headway in this area and find out more about the key benefits that hybrid wide-format print technologies offer to companies in the sign-making sector.

Flexibility is key

One of the leading names in the wide-format sector is EFI, which cites its VUTEk h series as an effective hybrid solution in this market. Paul Cripps, vice president for European sales at EFI, says the machine delivers higher productivity, print quality, reliability, capability and profits.

O Factoid: EFI’s VUTEk h5 model can produce up to 109 boards per hour in X4 mode. O

“It is the culmination of EFI’s decades of experience in signage and graphics production technologies, as the world’s leading manufacturer and developer of LED inkjet superwide-format printers and inks,” Cripps says, adding: “The series’ new, high-velocity seven-picolitre UltraDrop Technology grayscale printheads deliver precision dot placement and consistency.”

The series offers eight colours plus white, a new X4 Technology optional printing mode, as well as up to nine-layer print capability. The VUTEk h3 prints up to 74 4ft x 8ft boards per hour in a CMYK x 2 configuration, while the h5 model, which is available direct from EFI or as field upgrade to the h3, can produce up to 109 boards per hour in X4 mode.

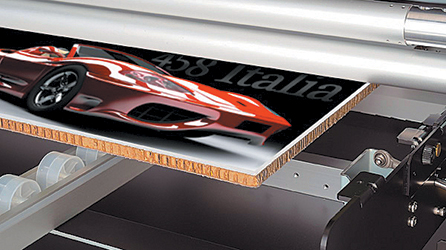

EFI’s VUTEk h3 can print up to 74 4ft x 8ft boards per hour in a CMYK x 2 configuration

But why go hybrid? Cripps explains that hybrid printers are capable of printing roll-to-roll, flexible sheets and rigid substrates, therefore offering what he describes as the “ultimate in flexibility”, allowing fast changeover from flexible to rigid materials and enabling cost effective production of a host of applications.

Cripps adds: “A production-level hybrid printer allows you to offer both rigid and roll work in a single unit, which means less floorspace is needed. It also means you don’t need a dedicated machine for rigid work and another for roll work. And that could be a significant cost savings.

A production-level hybrid printer allows you to offer both rigid and roll work in a single unit, which means less floorspace is needed ”

“Although you can print flexible substrates on a flatbed printer and rigid substrates on a roll-to-roll printer, you often at times have to purchase those capabilities as an option which may not have been designed to handle higher-volume work.”

Versatile solution

Elsewhere and Roland DG is known across the market for its hybrid wide-format print kit, with its LEJ-640 hybrid UV LED flatbed printer proving popular with customers in a range of industries.

The LEJ-640 has ability to produce high-quality CMYK print, utilise white ink and create textures with gloss ink, which, according to Rob Goleniowski, head of sales in the UK and Ireland for Roland DG, provides impressive, premium results.

Roland DG’s LEJ-640 can produce high-quality CMYK print, as well as utilise white ink and create textures with gloss ink

Goleniowski says: “For everything from signage to point-of-purchase displays, packaging to membrane panels, the LEJ-640’s media compatibility makes it an attractive investment for customers looking to extend their product offering.”

The LEJ-640 hybrid UV LED flatbed printer from Roland DG can be used to create applications such as signage and point-of-purchase displays

But what are the benefits of hybrid kit over standard wide-format technologies? Goleniowski points to how hybrid solutions provide a comfortable entry point for businesses that want to print on rigid substrates, but are not yet ready to invest the capital and floorspace on a full flatbed solution.

Goleniowski highlights how there is a much lower investment required when compared with a full flatbed. Using the LEJ-640 hybrid printer as an example, he says this typically sells for £36,999, whereas a professional entry-level flatbed could cost around £75,000.

But there is more to hybrid kit than just cost, as Goleniowski explains: “Another benefit for small- to medium-sized businesses is that hybrid printers usually have a much smaller footprint than a full flatbed, especially when tables are not being used, meaning the company doesn’t need to pay more for extra floor space.

“Hybrid devices also let businesses produce rigid products in-house rather than outsourcing, retaining the production quality and increasing margins. Since a hybrid printer is such a versatile solution, users can also print roll-fed media for standard applications like vinyl signs or window graphics. The resulting profits can contribute to a future investment in new premises or a full flatbed solution.”

Stepping stone

Delving further into this market and Fujifilm has its Acuity LED 1600II large-format hybrid printer on offer to companies seeking a flexible solution. The machine runs UV inks, which, according to Fujifilm, are scratch resistant and outdoor weather safe, thus removing the need to mount and laminate materials.

The Acuity LED 1600 II

The Acuity LED 1600II also has the ability to embellish the results by utilising an eight-colour inkset, which comes as standard on the machine.

Martin Burton, showroom manager at Fujifilm UK, says that the versatility of the Acuity LED 1600II, as well as hybrid print technology in general, is the greatest benefit for users of this type of kit.

Burton expands: “Hybrid printing is the perfect stepping stone from roll-to-roll devices for customers who would like the benefits of being able to use LED UV ink and print directly onto rigid materials, as well as still be able to deal with their roll-to-roll printing requirements.

“Hybrid printers are a half way house to purchasing a flatbed printer for ultimate print productivity on rigid materials. They do take up a little more room than a flatbed with tables on as they convey the material, but when the tables are not in use they can be folded away.

“Though the productivity doesn’t compare to a flatbed, pricing is around a third of the price.”

A different approach

While the majority of industry members will have a certain understanding of the term ‘hybrid’, OKI offers a different, yet through-provoking, definition. Frank Jänschke, senior manager, EMEA, wide-format and product management at OKI Europe, says that the manufacturer defines hybrid as a multitalented, versatile printer necessary to fulfil the demand out of the market.

Jänschke gives the example of the OKI ColorPainter series, saying that they are able to produce photo quality indoor prints, right up to the highest durability outdoor applications. This can all be achieved using one type of ink that is Greenguard Gold-certified.

Although not classed as traditional hybrid, OKI sees its ColorPainter series hybrid in terms of being multitalented and versatile printers

He expands: “Our ink gives the highest pigmentation and biggest colour gamut to create the application, ranging from wallpapers and textiles, to posters, canvas prints, floor graphics and backlit applications – all with full colour.

“The same ink and printer gives the highest UV durability in the market and colour accuracy in tiling jobs for high quantity of campaign jobs on several medias.

“Yes, we offer roll-to-roll printers without the flatbed option, but for all these versatile applications in high quality, you would normally have two printers with different inks. However, we can offer one that will handle most applications for both indoor and outdoor usage, thus saving on costs and floorspace.”

While wide-format and large-format are often talked about on a more general basis, the further you look into these markets, the more solutions you discover. In the case of hybrid printers, this type of technology could prove to be a smart investment for companies new to the sector and are looking to save on initial costs when getting started with wide-format print.

However, the wide-format market extends even further, to the point where sign-making companies in particular may be seeking a solution that will allow them to take on much larger work. In the final feature in our special wide-format series, we will be taking a look at super wide-format print kit and the benefits this can offer to your business.

Check back in SignLink November to find out more about this technology and the type of work you can expect to take on by investing in new kit.

Your text here...