Investing in a new CNC router may just be the road you want to follow

Follow the lines

When you cast your mind to CNC routers, you may think that investing in one could be a particularly pricy way to go. However, as there are both entry-level and top-end Computer Numerical Control Routers available, it could be the best decision you have ever made.

The concept for CNC routing was introduced in 1949 and in 1951, the first CNC Router was built. It was based on a milling machine and didn’t exactly light the world on fire – but sign-makers can still thank John Parsons for his ideas over 60 years later. Back then, the routers were not computerised but thankfully this was something that developed over the decades.

O Factoid: CNC, or just NC routers at the time, were introduced in the late 1940s and 1950s. O

Investing in a CNC router will automate the cutting process, which will obviously save you time and perhaps even people power. There are pitfalls when it comes to purchasing a router and there are some points to avoid when making a decision. Make the correct, informed decision and you’ll be laughing through all your cutting needs.

There are some pitfalls to avoid when purchasing a CNC router, but working with a manufacturer or reseller can help

Some of these pointers may help you choose between an entry-level off-the-shelf solution and a more expensive, customised option. Sometimes, turning to an entry-level solution could be less than cost effective as its production capabilities may be lower than what was quoted. Of course, this is not always the case. However, if you work together with a provider to come up with a solution that is a perfect fit for your business, has an even higher capacity than you might necessarily need to begin with, and has more capabilities is also a good option. This will come with a higher price tag, which will be daunting in the current climate of uncertainty, but in the future, you will be able to take in even more cutting work.

Further benefits of working with a supplier means that there is support on offer when you require it, and there is also help available when something goes wrong – in terms of purchasing replacement parts or needing an engineer to help. Throughout their life, CNC routers will also need to be serviced, which is another advantage of working with the manufacturer or reseller. Sometimes, accessories are also an option – like Automatic Tool Change (ATC) systems to involve multiple tools.

Infinite possibilities

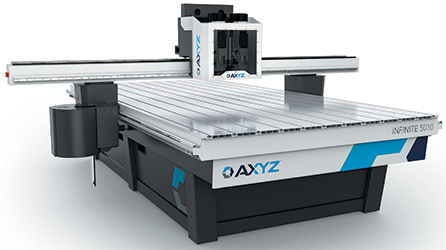

This year, AXYZ went through a rebrand and restructure to become AXYZ Automation Group. It also presented the Infinite router, PANELBuilder and WARDJet machines.

Theresa Scarth, UK general manager for AXYZ, explains more on the evolution of the Infinite machines: “Building on the legacy of previous AXYZ machines in terms of outstanding build quality, reliability and enhanced productivity, the AXYZ Infinite combined routing and knife-cutting system is said to have to set a new benchmark for CNC machine performance.

The Infinite 5010 is part of the new Infinite series from AXYZ Automation Group

“Key design features include the now familiar solid steel frame construction to accommodate the most vigorous machine operation likely to be encountered and a new carriage design that enables much easier access for servicing and installing machine tool upgrades.”

Scarth also highlights some of the added extras that are available for the Infinite series. These added extras will obviously increase costs, but when making a decision about investing, researching all the optional add-ons could be beneficial to sign-makers. “As with all AXYZ machines, Infinite is available with a raft of standard and/or optional machining enhancements,” says Scarth, adding: “These include an expanded – up to 33 stations – ATC system, the AXYZ Zone Management facility for optimum material hold-down efficiency and the latest A2MC machine controller with integrated AVS (AXYZ Vision System) for precise routing/cutting accuracy.

As with all AXYZ machines, Infinite is available with a raft of standard and/or optional machining enhancements”

“Optional VECTRIC VCarve and Aspire design and production software – supplied as part of a package – provide all of the necessary tools for 2D and more complex 3D applications.”

Having these sorts of options available to you means that you can concentrate on different types of work – one of which is 3D letters, much like Scarth mentions. Housing a CNC router in your arsenal that has the capabilities means that sign-makers can create more complex projects using products like SIGNBLOCK. This is available from Indasol and is a high-density urethan (HDU) material for 3D letters, shapes and signage. “When used on a CNC router, you are able to not only route out the shape, but also reverse route to create a void for lighting and create a built-up sign or letter,” says Martin Sadler of Indasol. “Offered in two main densities and a range of thicknesses, SIGNBLOCK allows the user to either CNC machine, hand carve, sand blast or even waterjet cut. As CNC is the most common, the standard thicknesses work well with all routers to achieve eye catching and effective installations.”

CoSign created this sign using SIGNBLOCK from Indasol, which is one product that can be used with CNC routing to create 3D signage and built-up letters

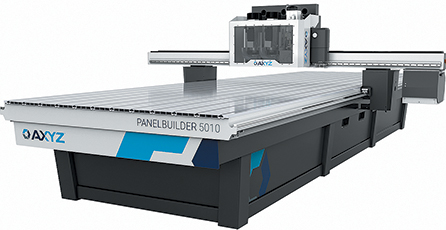

Also in AXYZ’s line-up is the PANELBuilder system, which has been designed for processing aluminium plates, stainless steel and metal composites among other metals. There are a number of options in terms of the processing area with 1,524 x 3, 048mm up to 2,519 x 12, 129mm and longer in increments of 600mm available.

The PANELBuilder from AXYZ is another option for sign-makers to look into when investing in CNC router technology

“Additional design features include a powerful vacuum-based

material hold-down system, an automatic mister/coolant device and pop-up

location pins for optimum material alignment. Waste material is safely

removed via a chip extraction system incorporating an automatic vacuum

extraction manifold,” says Scarth.

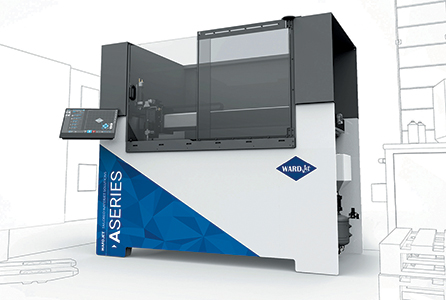

The WARDJet series from AXYZ is a range of waterjet cutting machines, with Scarth highlighting the WARDJET A-0612: “A new smaller-format waterjet cutting machine has also been introduced by AXYZ Automation Group. Called the WARDJet A-0612, it will process a diverse range of materials that traditional CNC routing/cutting/engraving systems cannot handle efficiently. Typically, these include steel and other non-ferrous metals, cast and wrought iron, glass, fibreglass and ceramics.

A-Series WARDJet

“With a smaller 213 x 124cm footprint, the A-0612 will fit neatly into any workplace where space is at a premium. A key benefit is that whilst similar waterjet cutting machines operate at pressures ranging from 30,000 to 45,000psi, the A-0612 will operate at 60,000psi, thus equating to the performance capabilities of much larger machines.”

Numerous solutions

Complete CNC Solutions are a Somerset-based company and offer CNC routers and digital cutters from Tekcel in several different sizes and in a number of price ranges.

Julian Sage, managing director of Complete CNC Solutions, explains: “A business buying its first computerised router is faced with a lot of choice. In terms of narrowing that choice to what may be described as ‘entry-level’ machines, it’s normally size and the extent to which the machine is equipped that meet somewhere on the journey with price that qualifies a machines being ‘entry-level’.”

Julian Sage, managing director of Complete CNC Solutions

He continues: “Concepts of quality in routers needs to be understood. Some superficially well-qualified machines achieve entry-level pricing by using lightweight components and less well-engineered builds. This is ultimately reflected in the quality of the output that can be achieved. Poor quality output costs a lot of time and money to improve manually to the point where it’s saleable.”

The most well-known entry-level router is the Tekcel VXR, with Sage commenting: “This system is firmly positioned at the quality end of the market and many sold to customers looking for an entry-level machine go on to survive the user’s growth phase and sit alongside bigger Tekcel systems still doing a valuable job.

“The VXR can be specified with a large range of retrofittable enhancements extending its capabilities further and despite its compact and thus affordable dimensions, this amazing entry-level machine throws a much bigger punch than many of its competitors.

“Entry-level machines are there to take a company forward. The Tekcel VXR does just just that – and it’s not easily outgrown.”

If you are looking for a router that is more suited to industrial production, the Tekcel EXR platform could be the solution. “The Tekcel EXR platform is available in sizes from 3X2M upward with its 4X2M stablemate better known as the Tekcel EXL,” says Sage. “These systems are massively built, extremely stiff and over-dimensioned in terms of drives and components. This is reflected in the quality of the output they achieve. Where lightweight CNC routers leave the operator with the job of improving the output they generate, the EXR produces output that’s ready to use right off the bed of the machine.”

The Tekcel EXR

Sage adds: “The system can be configured with options that extend its remit to flatbed film cutting or exact registration routing, or knife cutting of printed flat materials. As anyone who has cut flat rigid materials knows, they’re rarely flat. That won’t trouble a Tekcel EXR user who’s equipped his system with Tekcel’s amazing Material Surface Probe. Engraving accurately? Suddenly, that’s no problem at all. Neither is cutting to precise depths from the material’s surface.”

A computerised router isn’t something that’s purchased on a whim, and unlike printers, routers can last for decades”

This is just a brief look into what is available out there for sign-makers looking to invest in a new CNC router. Whether this is at an entry-level or a more industrial level, investing is still important as these machines can last for a very long time making them cost effective if you make the right choice. Sage concludes: “A computerised router isn’t something that’s purchased on a whim, and unlike printers, routers can last for decades so the relationship with the vendor is going to be a long one.”

Your text here...