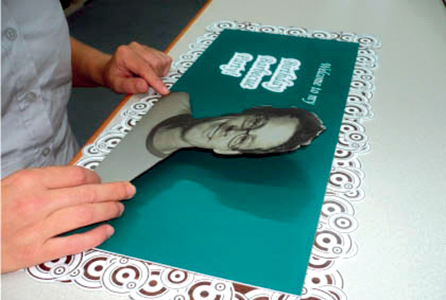

Brunel Engraving has a wide breadth and depth of technology at its disposal. Pictured: A special one-off commission for SignLink magazine’s front cover image

Recently, the film world has been waiting with bated breath to see if one man finally had his dreams realised by winning his first—and well-deserved—Academy Award. Leonardo DiCaprio, evolving from teenage heart-throb to gritty indestructible hero, finally held high the Oscar he achieved from struggling through icy terrains in The Revenant, much to the celebration of fans worldwide, who had been clamouring for his official recognition.

Though of course winning an Oscar is much more than the physical award itself, it is the image of this revered industry victor holding tight to that iconic golden statuette that will stay with audiences a lot longer than his new moniker, ‘Best Actor 2016’, and his name engraved on the plaque beneath will stand proud long after DiCaprio is gone.

It is undeniable that the etching or engraving of names and images onto materials is something that resonates very deeply with us, from youngsters carving their initials into trees to mark their presence at a certain time, to CEOs proudly displaying their names in brass plaques fixed to their office doors. Despite, and perhaps because of, our steady movement into an era of digital transience, the desire to ‘make our mark’ is no less strong. The solidity and permanence of etched and engraved materials is one that birthed an intrinsic branch of the sign-making industry, and has kept it fine fettle since the dawn of civilisation.

(Above & below) Applications in etching and engraving can range from built signage to textile accessories

It is true that the engraving industry used to span many more applications than signage. Traditional printing presses (and some more modern equipment) required etched metal plates from which to reproduce the first printed pictures and engraved type/lettering to generate books and newspapers. Additionally, the art world flourished with its use of etched wood and metal, with artists like Hogarth, and earlier Greek and Roman engravers finding much fame in their skilled hand-engraved works.

Yet the world moves on, and while digital printing and digital design have taken hold, there is still somehow a great commercial demand for engraved and etched products. That is not to say the technology, techniques, and products of this ancient craft have remained in the dark ages, as Peter Kettle, business development manager at Roland DG is adamant about: “The engraving industry has emerged as a remarkably creative one that can open a world of possibilities to professionals across the country. Whether producing plaques and signs or creating personalised corporate gifts, when using the right tools, there are huge opportunities to thrive.

“I don’t believe adopting engraving is returning to what might be considered old fashioned. Instead, we are utilising the latest software and PC capabilities to deliver new levels of complexity through a tried and tested technology.”

Making your mark

Bolstered by technological advances, the engraving market is branching into many areas that sign-makers may not have considered before.

Kettle has noticed many new applications emerging as sign-makers put their equipment to the test. For example, he says: “The trend we are seeing recently is engraving multi-level rigid signs, which are as much about art as they are delivering information—nearly bordering on sculptures! Modern engraving design programs are very advanced in their capabilities, meaning that even novice engraving professionals are able to produce remarkable items with the right software.”

Modern engraving design programs are very advanced in their capabilities, meaning that even novice engraving professionals are able to produce remarkable items with the right software”

However, before delving into the realms of software, it is important to grasp exactly what equipment is out there and what a sign-maker needs to break into these new markets. According to Kettle, the key features a sign-maker needs from an engraver is simple operation and reliability. He says: “Of course, it has to be accurate, powerful, versatile, etc, but there’s no point in buying the most advanced solution if you can’t make work.”

Kettle continues: “Innovation in engraving is tough. This is mature technology, and you shouldn’t fix what isn’t broken. Having said that, our Metaza MPX-90 impact engraver is a miniature marvel. If you are looking to explore the lucrative and growing market of personalised products then this is an engraver with the ability to permanently engrave both vector and bitmap images. It really is a fantastic and affordable way of personalising metal gifts, giving the prestige finish synonymous with diamond engraving.”

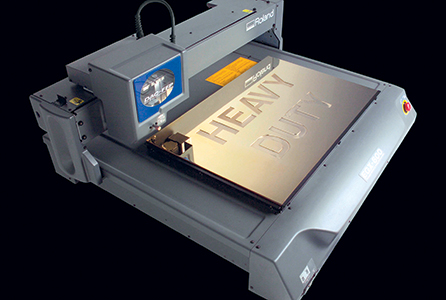

For larger outfits, Kettle recommends the EGX-600 Pro Series range, which aids sign-makers looking to take full control of their engraving, perhaps by bringing it in-house, in order to maximise profit margins. An integrated solution, this range provides heavy-duty engraving power as well as supporting an easy-to-operate interface. Kettle claims: “The unrivalled accuracy from the machine guarantees items are delivered to the highest standard, meaning users are able to offer a superior service and benefit from premium costing and a larger return on profit.”

Roland DG's EGX-600 offers an integrated solution with heavy-duty engraving power as well as an easy-to-operate interface

Set lasers to stun

One major development in the field of engraving was the introduction of laser technology in the early 1960s, which many found to be a beneficial alternative to standard engraving methods for a number of reasons. Lasers tend to allow for more precise designs to be created and for smaller, more delicate items to be etched or engraved. On top of this, some have argued that laser engraving is cleaner, as it does not require the use of harsh chemicals or high temperatures, and no dust or chemical residue is left over.

Austrian manufacturer Trotec Laser is one of the forerunners in this field, and have a range of CO2 and fibre laser machines they are developing to help businesses stay ahead of the game. Trotec’s Speedy Laser engraver series has been designed to give their customers a range of high-speed engraving solutions to tackle a variety of different applications, from entry-level to professional outfits.

The Speedy engravers come in four sizes, the 100, 300, 360, and 400, depending on the required output needs, with a maximum process speed of 3.55m/s and an acceleration of 5g. Each machine comes with an option of CO2, fiber, or combination laser source and have the potential to handle a vast array of substrates, from wood and metal, to acrylic, glass, and even textiles such as leather. This opens up a huge range of applications for sign-makers, who could find new business avenues by offering personalised corporate accessories alongside their signage contracts.

Trotec Laser claim that their Speedy laser engraver range is the fastest on the market and is able to cater to many different applications

Trotec are well known for their creative approach to applications, claiming that the only limit to their machinery is the user's imagination. On top of traditional (yet lucrative) engraving markets we all recognise, such as promotional items, trophy engraving, and creative signage, they cite the potential to use their machinery for applications spanning from architectural models to breaking into the packaging market. They demonstrate these various ideas on their YouTube channel in tutorials run by their own machine demonstrators.

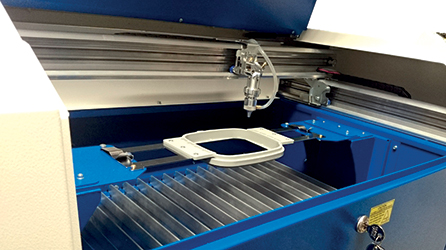

Northampton manufacturer CTR Lasers also boasts the benefits of laser technology with their range of CNC laser cutting and engraving machinery. The company proudly cite their machinery to be British-manufactured, and offer a huge range of different equipment. CTR Lasers offer both standalone engraving equipment, but also combination engraver and cutters, which are especially useful for creating and embellishing uniquely designed items for customers.

Their new TMX12, 65, and 65-E machines are CO2 laser engravers and cutters with work sizes of 1200 x 900mm and 650 x 450mm respectively. With the additional cutting element, CTR Lasers identify many markets that could be opened up, such as model making and shoe making.

CTR Lasers offer a wide range of laser engravers, such as the TMX65-E which is easily integrated with other machines to expand application opportunities

Aside from the combination of cutting and engraving, the TMX65-E is specially designed to work alongside embroidery machines, for sign-makers who are looking to advance in the lucrative textiles and personalisation market. The machine is adapted to allow different embroidery jigs to be attached, meaning materials can be immediately cut and trimmed after the embroidery work is finished, saving on production time and ensuring accuracy and consistency across orders.

Pedal to the metal

One company that is making waves in the field of engraving is North Somerset's Brunel Engraving, and they are doing sterling business.

Though things have been remaining steady in terms of technological developments, recently Martyn Wright, managing director of Brunel Engraving has noticed a significant increase in demand for engraved products across the board, mostly due to changing markets. He says: “We attribute this to an increase in demand for personalised products and the need to advertise a company’s branding on equipment.”

It is, continues Wright, the combination of these new markets with the continued public perception of engraving to produce a long-lasting, high-quality product that accounts for its continued popularity.

O Factoid: In 1916, Albert Einstein developed the theory of radiation which led to the development of Light Amplification by Stimulated Emission of Radiation, or laser. In the early 1960s, this technology started to be used in industrial engraving. O

Wright says: “Engraving has always provided a more permanent sign as it is cut into the surface of the material. Etching will give similar results as long as the etch is deep enough, both methods result in a design that cannot be erased without removing the material surface. This process is seen to provide a better quality, more permanent product than modern sign-making.”

This attitude is somewhat proven by the kind of clients Brunel Engraving attracts, such as when the company was contacted by a leading global specialist in classic MG cars, who have been restoring the magnificent vehicles for over 25 years.

(Above & below) Brunel Engraving has carved out a niche for itself in the car restoration market

Wanting to add the finishing touch to every one of their cars to identify that it had been built by MG, Brunel was commissioned to create unique sill plates that were designed and manufactured from the highest quality materials to give the cars the recognition they deserve, and their owners a sense of bespoke, superior manufacturing.

The plates were manufactured from 316 grade stainless steel then cut to exact size. With the artwork approved, and a tool path created to ensure total accuracy, the plates were then then deep engraved using a spindle running at 60,000rpm with the distinctive MG logo and information personalised to the car. The deep, permanent engraving was then partially coloured to match the branding.

Sales director Ed Braclik notes that the engraved plates add an important element to the restoration of the cars, saying: “This has enabled us to offer an even more bespoke service to our customers while maintaining, if not increasing the quality of the final detail.”

Brunel has carved out a niche in this particular field, having also caught the attention of Bensport, who restore Bentley and Rolls Royce cars.

Etching out a future

In essence, the etching and engraving field is clearly not one that should be dismissed as one that is limited to what can be achieved with traditional methods. As Roland DG's Kettle says: “Engraving is an effective way for sign-makers to explore additional creative techniques that can expand product lines for businesses and accelerate business growth. For me, the future of engraving is firmly with the sign-maker in creating high value ‘carved’ signs; plus, as a method of profile cutting printed rigid substrate signs.”

Engraving is an effective way for sign-makers to explore additional creative techniques that can expand product lines for businesses and accelerate business growth”

However, aside from cost and imagination, Kettle identifies that one of the biggest barriers to a sign-maker taking up engraving is purely in perception, and again, the answer lies in technology. He says: “The biggest concern for nearly every sign-maker is the perceived complexity of engraving. When they hear you talking about tool pathing, feeds and speeds, they are immediately worried and begin having second thoughts. Admittedly you need to know a little bit about materials and cutters, but the powerful and intuitive software does all the hard work.”

All manufacturers these days, including Roland, ensure that each machine comes equipped with a comprehensive software package that takes the burden of complexity away from the user, and allows them to dream big. As Kettle says: “All that’s left—which model to choose?”

Your text here...