It is not a case of one fixture fits all

Holding the industry together

Signs are used in such a huge range of environments that they can often fade into the background and become overlooked. Take high streets for example, every single shop front has its very own bespoke sign informing passers-by of their service. Another thing that gets overlooked is how those signs get up there in the first place. With every impressive design, comes a number of nuts, bolts, and other fixtures holding it all in place.

One factor to take into account when considering fixtures, is that signs are predominantly read side on. It is not simply a case of one fixture fits all and it is important to know whether fixtures will be visible, look unsightly or even distract from the sign itself.

Low quality fixtures, or fixtures that are unsuitable for particular installations can mean that beautifully crafted signs run the risk of falling and being ruined – not to mention the risk to health and safety and time spent having to return to the site and re-install a sign that did not need to fall down.

Hanging fittings are popular in retail for wayfinding

Highlighting the importance of choosing the right fixture and fitting, London sign-maker, Glyphics, writes in a blog post: “We believe most people actually falter when it comes to putting up signs. Fittings are a frequently under considered part of sign design.

Fittings are frequently under considered part of sign design”

“Remember quality is key and giving a small amount of attention to this tiny little detail can be transformative to the overall look and feel your sign achieves, in a big way.”

The run through

On the surface, it may look as if all screws are of a similar make-up. However, there are in fact dozens of different types. Glyphics offers an extensive list of the various types of fixtures available in sign installations.

The guide lists plastic rawl plugs as the best option to give extra grip in solid walls and toggle bolts for hanging heavy elements onto a dry wall. Wood screws are suggested as the best option for timber, and steel tapping screws for threading through metals or plastics.

O Factoid: The screw first appeared in machinery during the time of the Ancient Greeks. O

For sturdier applications, the firm lists chemical bolts as the go-to fixture. The high-strength metal fittings are set with a hardcore resin and are best suited for solid substrates such as stone or brick.

Other fixtures include stud fixings – thin rods which mounted to the back of flat panels or letters and can be attached by pushing or gluing into pre-drilled holes. Locator fixings are made of two parts that fit together and can be screwed or glued onto plastic, wood or metal signs.

Stand offs are small fixings which consist of male and female parts. The female back section is attached to a wall surface by an internal thread and the male front section is threaded through a hole in the panel.

Stand offs are small fixings which consist of male and female parts

A fixture option which is popular in retail for wayfinding are hanging fittings. These are height adjustable hanging wires that are attached to the sign and screwed into the ceiling.

No unsightly fixtures

Button-fix is a comprehensive range of panel fixing products, manufactured in the UK and distributed globally. The company won the award for ‘New Product’ at the British Sign Awards, held by the British Sign and Graphics Association (now known as ISA-UK). The solution was formed when joint creators, Tony Wills and Brian Watson experienced a customer demand for flush invisible mounts to fix washroom panels.

The Button-fix range of fittings

The firm’s first fasteners were launched in 2012 and the latest, a zinc diecast version, will be available from May, illustrating an ongoing commitment to product innovation.

Conceived by product designers Wills Watson+Associates while working on a washroom project, Button-fix has been used in a wide range of applications, from bath panels to acoustic panels and from art installations to yacht fit-outs. “The principle of Button-fix is simple,” says designer and director Brian Watson. “Yet our customers use them in increasingly imaginative ways and with a very broad range of panel materials.” The company even introduced a bonded version to address applications with thin panels not suited to screw fixing, such as acrylics, metal, glass or solid surface materials.

Durable nylon buttons are attached to the back of one panel and the mating fixes are attached to the other, installers simply need to bring the panels together until the button-fixes ‘click’. The Button-fix is completely invisible with no bolts or screws on show and features a Marker accessory which enables installers to accurately align the button-fix installation, without the need for a tape measure or guess work. The fixture is also proven to be strong, having been extensively and independently tested.

The Button-fix comes in four types meaning there is a fixture for any installation. Type 1 connects parallel panels where the emphasis is on strength. It is a versatile option which can be surface mounted or semi-rebated into the panel, oriented for vertical or sideways assembly. Type 2 connects panels at 90 degrees and engages with a straight push. This version is ideal for panels with no clearance above or at the side and applications where the emphasis is on ease of access.

Type 1 Flush is designed for applications where panel-to-panel contact is required. It fits a simple oval rebate and can be rebated into the edge of a panel of at least 28mm thick or the face of a panel of at least 18mm thick. Type 1 Bonded is for use where screw fixing to the panel is not possible and bonding is the preferred option. It can be either surface-mounted or semi-rebated and works with a broad range of materials.

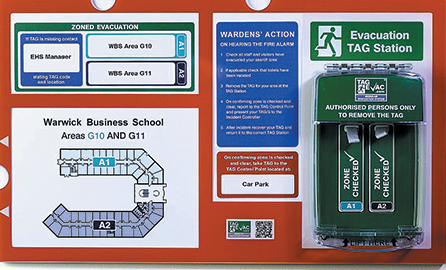

Thanks to this versatility, Button-fix is attracting customers in the signage sector. Customers such as TagEvac have found it an ideal solution for installing statutory fire escape maps, using the Type 1 Bonded Fix attached to aluminium-composite printed panels. All the fixings are concealed; however, it is still easy to remove and replace the sign if the information requires updating.

Button-fix customer TagEvac uses Type 1 Bonded Button-fix to mount its TAG station sign panels. Image: TagEvac

Watson explains: “The Marker Tools are what set Button-fix apart in the market. Secret fixings are renowned for being tricky to install accurately, but with Button-fix the Markers take out all the guesswork or complex measurement. Simply snap a Marker into each Fix, align the panel and press firmly – indents will show you where to install the Button. No tape measure required.

“Customers are demanding increasingly higher levels of performance from fasteners, which is why Button-fix has developed an all-metal version for use with fire-retardant panels or in transport applications, where vibration may be an issue. The new Type 1 Metal Fix features a stainless-steel spring to grip the Button. The familiar and reassuring ‘click’ as the Button-fix locks home has been tested over 10,000 times, to ensure reliable performance no matter how many times the panel is removed.”

In a statement on the firm’s website, co-founder, Tony Wills says: “Completing projects as quickly as possible, but without sacrificing quality is a constant challenge for those operating in the construction trades. Button-fix is gaining traction in the market because it helps tradesmen working in domestic or commercial settings to meet the challenge.

“With Button-fix, all sorts of panels can be aligned and installed much more quickly and with a higher degree of accuracy than old-style fixings and connectors. What’s more, the fix is both incredibly strong and completely invisible – with no unsightly bolts or screws on show.”

Getting the installation right

Due to the bespoke nature of the sign industry, it is safe to say that generally, no two-sign design is the same. Therefore, it would make sense that each installation will require a particular type of fitting.

Colorado-based Stonehouse Signs provides a range of different signage solutions. The firm outlines the various methods of installation needed for each product – these guidelines are just one example of the number of different fixtures and fittings available for sign installations.

For its LxSign, the firm recommends mounting using fastening devices such as bolts and screws which are slightly smaller than the sign holes. Stonehouse Signs advises installers not to over tighten fastening devices to prevent bowing of the sign.

The firm also recommends using a rubber spacer to protect against over tightening and allow for thermal expansion and contraction of the LxSign material. As well as using nuts and bolts, most signs can be mounted using an appropriate adhesive or double-sided foam.

As well as using nuts and bolts, most signs can be mounted using an appropriate adhesive or double-sided foam

For self-adhesive vinyl installation, Stonehouse Signs’ products come with a permanent acrylic adhesive on the back. Maximum adhesion strength develops in 48 hours when applied to clean surfaces. When completing the application, the firm advises wetting the surface with mild soapy water to allow for positioning of the vinyl and warns against applying to a cold surface which can make the process more difficult. By smoothing the surface of the vinyl from the centre outward, any wrinkles or bubbles will be eliminated.

The wide selection of fixtures and fittings available means that the potential of what each sign installation can achieve is endless. With each type of fixture boasting its own specific strengths and special purposes, it is just a case of finding the best type for the job.

Your text here...