Think

Think

‘Ink’ is a very small word for something that is today among the most used of all the staple products consumed by the sign and allied industries. Ink, of one species or another, flows through at least one piece of manufacturing hardware in practically every sign and graphics shop in the country.

Today, the overwhelming majority of ink that is used by the sign industry is ‘digital’. That is to say, it is delivered to the target substrate by a digital printer, usually a wide-format inkjet printer, though other formats are out there and doing useful jobs. Inkjet printing has largely displaced screen print and other print technologies for sign-making applications.

Digital inks are minor miracles. The interplay of physical and chemical property makes them possible. Pictured: the high-tech laboratory at Industrial Inkjet

Screen printing was, and what remains is, a process that can deposit practically any printable medium in controlled thicknesses upon practically any substrate. By comparison, digital printing is more narrowly talented. Narrowly talented maybe, but widely applied and even more widely practiced. That is where the focus of ink use today is directed.

In order for digital inks to work at all, they have to conform to very precise physical and chemical prescriptions. These prescriptions limit the composition of the ink, the amount of pigment it can carry, and numerous other critical factors.

In order for digital inks to work at all, they have to conform to very precise physical and chemical prescriptions”

A single droplet of ink jetted by a modern inkjet printer is in the pico-litre ranges. A pico-litre is a millionth part of a millionth of a litre. As might be imagined, it takes a lot of droplets to form a recognisable image. It takes many more droplets still to start building mass, textures, and other variations on the basic theme.

If an ink design ventures beyond the performance envelope a given print head can accommodate, the ink either will not jet at all, or it will not form droplets reliably. Ink manufacturers then have a very limited range of options when it comes to mixing alternative ink brews for different target applications given the prevailing ink delivery technologies at the heart of today’s hardware.

That being the case, what distinguishes inks apart and where does the industry turn when looking within the available ink market for things that might support new creative applications or even open new markets?

Getting it right

Views will vary on this subject but, among many, there is a marked reluctance to put alien liquids in the device that one’s business depends upon. For that reason, manufacturers’ original inks tend to be the favoured port of call for wide-format inkjet owners. The cost of using a manufacturer’s original ink, when divided into the cost of all the square metres of print that is produced, amounts to not much at all in terms of the bill of materials attributed to a given job.

Putting a bit of money into a top-quality approved inkset can be thought of as putting money on deposit that you get to withdraw when you sell on a completed job. You get the money back in other words. It is hard to see a saving justified when you are struggling to bring a printer out of a coma on a Monday morning with a week’s worth of deadline dependent material there in the workshop that needs doing.

For the most part, the inkset you specify on day one when you acquire a wide-format inkjet is the one you work with until the printer is retired. Changing inks is possible, but not something taken lightly and certainly not something that can be done on a job-by-job basis. Indicated action: choose wisely.

Choose the inkjet your business will depend on wisely as getting it wrong will lose you customers and money

Basic inksets comprise the four process colours. Not that we need reminding, but those colours are cyan, magenta, yellow, and black (CMYK). Yes, the ‘K’ is black and is probably a throwback from the days when printers dealt with ‘key’ layers in printed jobs.

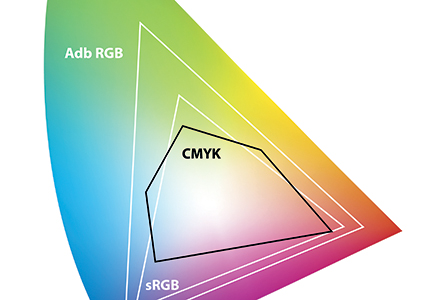

Four colour inks deliver the basic gamut and other colour sets can extend this. Light colour improve gradation rather than extend gamut

CMYK inks deliver you just what is needed to print four-colour jobs. Not all CMYK ink is created equal. Some inksets liberate more gamut or extent of colour than others may. Again, the better-quality inks get you to the most productive and useful parts of the available spectrum.

In terms of the creative potential available, even with this most basic of setups, it is measured in all dimensions and can be thought of as ‘considerable’. The inks you choose will print upon a bewildering range of substrates for a start. You can therefore print anything from gloss so deep you could swim in it, to a finish so matt as to barely let the light out. You can print upon materials that have very pronounced textures. You can print upon clear materials and any number of opaque ones too. Naturally, you can adhere these materials upon all manner of substrates from walls to vehicles, floors to windows and more.

The basic four-colour setup is a versatile setup indeed. The creativity quotient though is as much a function of users’ talents as it is anything to do with the ink itself. Ink is usually encountered in more sophisticated variations these days and basic four-colour is something of a minority interest.

One off-base alternative that is encountered is the dual CMYK variation. That is where you have two inksets, each CMYK, arranged to deliver ink through eight outputs. More often than not, the inks are arranged thus: CMYK KYMC. The thinking behind such arrangements is that extra print speed can be found while minimising quality trade-offs. If you print 100 percent yellow upon a swath of 100 percent magenta, you product a swath of red. If you do it the other way around, you end up with red too but a very slightly different one. This effect makes itself obvious in an aberration or artefact known as chromatic banding. With the dual inkjet, that artefact is managed and printers can deliver print produced in bi-directional modes with better apparent quality.

You would have to dig deep to find a creative justification for dual CMYK setups. It is primarily a productivity driven consideration.

Four-colour, more colour

Basic four-colour setups start to look a bit wobbly when the output they yield is compared to output from printers running Lc and Lm inks. Lc and Lm are respectively light cyan and light magenta. They are added to the basic CMYK variation, not, as many suppose, to produce more colours, but to yield better quality.

Print hardware simulates tones and densities of colour with a whole range of internalised trickery that boils down to the size of the dot and where it is made to land on the substrate. Look hard enough and those tricks are evident in the output in the form of non-physical textures and little blobs or ‘dots’ as they are called in polite company. If you are able to print a 50 percent tint of a colour without recourse to the texturing and dot arrangement book, you will get something that looks ‘smoother’.

Smoother is good. Smoother gets you from one tone to another more, well, smoothly. The transition across tones is widely referred to as ‘gradation’. It is a tough thing for an other than expert eye to judge, but when you can compare results side-by-side, it is much more obvious. That clunky journey through the available gamut in a four-colour device, when called to account by the more sophisticated delivery of a printer with Lc and LM up its sleeve looks like part of a different strata of quality. Those expert in judging print would prefer the better variant.

Before getting into the creative potential the ‘better’ delivery of colour delivers, it may be worth touching upon why yellow is absent at the light colours’ party for the most part. It is complicated. Let us just say, it is very hard for the eye to even see lighter tones of yellow on white materials. Your friendly printer engineer may carry a blue torch with them. That so they can shine it on their test prints. White reflects the blue light, yellow soaks it up and so looks black under blue light. Speaking of black. Light black takes a bow in some inks too. It is there for the same reason as the other light colours.

Back to this notion then of ‘better’ colour and what you can do with it. More is the basic response. With a quality inkjet in a quality printer, think Agfa, Roland, Mimaki, HP, Epson, and a host of others, you can spit out stunning full-colour print in broad daylight. Those prints these days are capable of satisfying markets that were, once upon a time, the exclusive and unchallenged province of photo-labs.

With better colour and the right substrate, you can make a passable attempt at producing what many would class as corporate art. Pictures good enough to frame and put on walls in hotels, offices, and the like. You will not reach the higher fractions of that market equipped as we have described, but you could see yourself commanding and getting pounds per square meter for your output.

In general, the ‘better’ the colour, the more of the available market is yours to go for. The emphasis in anything that is colour-led is quality. Sell to quality, buy quality, think, eat, and breath quality, and you will find yourself on the right track.

Ink is interesting stuff and its study, and your output, gets more interesting still when you start to factor in what you might choose to call ‘exotic’ inks. It has been around so long that it is now regarded as a staple and not even a remarkable one at that. White ink though, is a very useful thing to have at your side and it is a pretty big technical accomplishment.

To get white ink, you will need to be on a solvent or UV print platform. White ink delivers what it says on the tin, white print.

There is not a lot of call for white print upon white materials you would think and you would be right. That may be more a consequence of the market not knowing that you have the capability, and you not promoting what you never get asked for. Maybe. Fact is, printing white ink on white materials can yield some very interesting result, results that someone out there will put hand in pocket and buy.

Calling all UV printers. UV printers tend to deposit ink that has a variable texture. Once deposited and cured, UV ink has appreciable physical mass that can be seen and felt. If therefore you print white UV ink upon matt or glossy white materials, it is going to be visible. It is going to be subtle, but visible nonetheless. That has potential.

Doing décor

If you look at Metamark’s Décor Mark portfolio of materials designed for décor applications, you will find some smooth white materials designed primarily for printing images upon that are subsequently adhered to walls. If you print detail on that very same material using white ink, you are left with an extremely marketable result. Solarise an image to two tones, print in white on white and apply. You will be amazed at the result and it transcends costs-plus. It looks valuable and it really is.

To repeat the earlier point, you are never going to be asked for this or anything like it. You have to offer it when you are presented with the opportunity, or create the opportunity to sell it yourself. It is worth the effort.

White ink is not exclusive to UV printers. The eco-solvent market gets it too. Roland DG’s Eco-Sol Max inkset has a white available and it too can be pressed to very creative purposes.

One very fertile area of creative potential if you have white ink available is to be found if you dive into the clear pressure sensitive materials that are widely available in the market. Clear materials and white inks, especially inks like Eco-Sol Max, play very well together.

White ink, by design, is there to provide a background for coloured ink when used on clear materials. It is also intended, with some print hardware, to provide a background for subsequent print layers if you are printing upon coloured substrates. Back to clear for the moment though.

The white ink delivered by eco-solvent printers does not have the density of the white a UV printer might and that might be regarded as limiting its potential. In reality though, this characteristic of the inkset creates potential all its own when you consider applications involving back-lighting print.

With one of Roland’s top-drawer printers and the Eco-Sol Max 3 inkset, you can produce sensational backlit transparencies that you would have once had to pay an arm and other assorted limbs for in a photo-lab. Simply backing that sensational ‘better’ colour with a smooth layer of white yields real pop and the sort of super-

saturated colour that advertisers love and the rest of us seem to prefer. It is up to you, as a commander of colour, to get what this output is worth.

O Factoid: With Roland DG’s ECO-SOL MAX metallic ink, you can transform normal graphics into metallic colours and effects, adding value to your product. O

Your Roland printer and its white ink can do a quite a few tricks with clear materials. Here is another that will see you dominating the backlit transparency market. It is an unwelcome characteristic of backlit colour print that it looks totally different in daylight conditions than it does at night when there is a light behind it. The reason is that, in daylight, the light you see has had, in effect, two trips through the ink layer. In backlit conditions, the emitted light has only had one trip through the ink layer. As a consequence, you are faced with having prints that look great, but only in one or the other modes of lighting.

You can produce backlit transparencies that work in daylight too by printing a second image on a piece of clear material without white ink and putting that, in close register, behind your transparency with that lovely translucent white layer. Now, regardless of the mode of lighting, light will have taken two trips through an ink layer and the result will be perfect day or night.

You can see lots of examples of what white ink makes possible at the Roland DG Creative Centre near Bristol. It is worth the trip because you will leave inspired. If even a fraction of that inspirations rubs off on the market you serve, you will make sales as a consequence and you will grow the available market in some way. Do not forget to let your customers know what is possible.

Seen and seen through

Sticking with white ink, those of you who have a UV printer configured around a white ink-set may profit from a conversation with Manchester-based Contra Vision. Contra Vision gave the world one-way vision graphics or see-through graphics as they are also popularly known.

If you have ever tried to print see-through graphics on clear materials without holes rather than use what you probably known as perf, the exercise will have taught you something about printer registration and how approximate it really is. With a bit of know-how and the right agreement with Contra Vision, those registration errors can be managed and it is possible to get print-only see through graphics out of your printer.

Making see-through graphics that way gives you the option of having them applied inside windows and you can include areas where solid fields are used too. Contra Vision calls graphics produced this way Impress and you need to practice the company’s ORS system to make them. Make the call first and you could be among those making a very good margin telling a new story that graphics buyers want to hear.

Returning to the eco-solvent technologies again, Roland and Mimaki both have a metallic ink available for selected printers they offer. As with many things that have a creative emphasis, the technology was there ahead of the demand and so, still, an opportunity exists for those who are prepared to take efforts on a pioneering footing and get out there and sell applications for the ink.

Again, it does what it says on the tin. Metallic eco-solvent ink upon a typical white substrate results in a lustrous, metal-like layer that catches the light. You can include it like a condiment within a field of conventional colour print, just like a little here-and-there accent. You can make it the main event if you choose. You can even combine the metal layer with the process colours to produce effects you would really struggle to get any other way.

Process inks are pretty much transparent. Print them upon the metallic layer the printer delivers and you get the target colour, but with a metal-like sheen distinguishing it from the other colour around it. It is startling, beautiful, and commercial in the extreme. It is not something a customer is going to ask you for so once again it is there to be offered. The effect can add tremendous value to print and that value is further reflected in the job’s creative basis.

Getting metal-like tints into print is an easy enough thing to accomplish where there is volume behind it. Once you venture into wide-format though and the volume is lower, it all starts to look a bit too hard and a lot more expensive. That is simply not the case if you have the metallic ink installed. You can produce metallic enhanced output on demand and your customers, if you tell them about it, are sure to really like the effect. You do not see much of it out there so it has value you would associate with exclusivity going for it too.

Clear inks have been around for a while now and have been used to amazing effect. Mimaki offers some for its UV print hardware and you would be impressed to see what effects this innocent sounding product can deliver.

A clear, digitally delivered UV cured ink is analogous to what most of us and the print industry in the mass thinks of as spot varnish’. Clear inks do what spot varnish does. Difference is, you do not need pricey origination to get the effect. Printed upon select areas of a conventional print, the clear makes the locality where it is printed pop.

While the above is true of Mimaki’s, and others’ clear ink, it is also limiting to think of it purely in those terms. The ink can be delivered upon the print in a manner contrived to impart various textures too and that has profound application possibilities.

Starting with the basics, it is possible to get a range of texture variations by tweaking the curing and ink delivery settings. Moving on, the clear layer can be, under digital control, printed upon itself to build layers and mass, that gets interesting.

Impasto is a well-known artists’ technique for layering paint upon itself and it is what contributes to delivering the distinctive texture that oil paintings exhibit with frozen waves of paint left solidified in the wake of a passing brush or knife. You can do substantially the same thing with clear (and coloured) ink layer using Mimaki’s tech.

Aside from making digital prints that might pass as something approximating oil paintings, this layering technology can add, literally, a dimension to print that would otherwise be absent. That flat croc-like lizard print can now feature something that begs to be touched. That is pretty potent at the point of sale. Leather like textures can be created. It is one of those things that, despite the expression being overworked, really is only limited by the faculty of imagination.

Layering technology can add, literally, a dimension to print that would otherwise be absent”

Venturing deeper still into Mimaki’s exotic reserve, we will find inks that defy conventional formulation physics by being expressly designed to elongate to extremes. Stretch a normal ink and it will typically break apart as it has no cohesive or membrane strength to speak of and it is held together by the substrate its printed upon. Stretch Mimaki’s specialist thermoforming ink, and it does not protest, it just elongates and keeps its composure.

Thermoforming is not an everyday application, hence the need for one of Mimaki’s specialist inkjet printers to handle the output. The application though is an attractive one and something that once required deeply specialised screen printing hardware to achieve. To see it delivered on an affordable digital platform is quite remarkable.

Mimaki’s specialist printers are capable of producing flat printed results suitable for subsequent thermo-forming operations

Printed textiles in the sign and allied industries in the UK, it is fair to say, lag the pace of development seen in other geographical markets. Make no mistake though, textiles have profoundly deep creative potential and significant traction in the market is coming.

Textile inks are special brews and feature colours not seen in the more conventionally cut inksets. Textile inks might include green, violet, and other such outliers to help the output achieve staggering gamut compared to what was possible only a few years ago.

Printed textile, and a system for mounting and displaying it, opens up the possibility of shipping output, seam-free and practically shoved in a box, to a retailer who can then mount the printed graphics in a tensioning system with nothing more than his own hands and a step ladder. That might be a struggle with other materials.

Once tensioned, textiles look like solid surfaces but can disguise poor ones. Huge in décor and retail, it is inks that make it possible. Inks and some very clever print hardware you can talk to Roland, Mimaki, and others about.

Inks really do liberate enormous creative potential. Potential though is what it will remain unless its promoted and sold to customers. The market will ask for what it knows you can make. It will not ask for all the creative things you can actually do. If this piece leaves you with but a single actionable item for you list, it is this: show and tell of everything today’s inks and hardware make possible. Creativity is latent unless sold.

Your text here...