The True Vis VG-540 is the cheaper of the two, coming in a 1371mm (54”) format

There are a number of eco-solvent printers on the market that are able to reach ever greater heights when it comes to the number and variety of products from an even more demanding client base. The ability of your customers to produce their own designs via desktop publishing software can be useful as they can have bespoke products, but printers need to be able to match the imagination of the customer by completing the difficult part, actually turning the idea into reality.

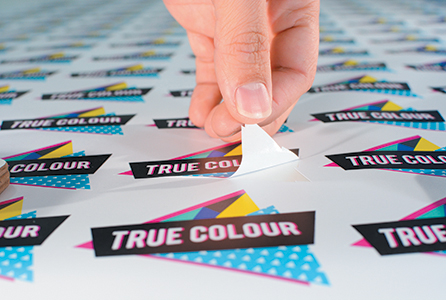

Adding to the complication of matching the customer ideas of design, they also now start to demand that these designs are printed on more and more different types of media. Add to this they will also probably want them to be cut with tenths of millimetre precision ready to be stuck to everything from windows to cars.

You would be pushed to think a group of engineers could come up with a product to be able to produce such a machine, but a bunch of clever people at Roland DG have come up with two machines that can actually roll all of these tasks into one eco-solvent printer/cutter.

This month we chose to look at the True Vis VG series printer/cutters. They are either in 1,625mm (64") or 1,371mm (54") format and known as the VG-640 and VG-540 respectively.

So, what makes these two machines so flexible and capable? When you read through the vast spectrum of media these printers can deploy high vibrancy colours to, it is very hard to find one that is not included. The range runs through rigid plastics, flocked materials, metallised and transparent films, mesh, cuttable vinyl, cork, polypropylene, and on and on and on.

When you read through the vast spectrum of media these printers can deploy high vibrancy colours to, it is very hard to find one that is not included”

How does the printer both lay down the types of eye-catching images and then when required, cut them accurately to be affixed to vehicles or all manner of point-of-sale displays?

At the heart of the printer is a newly designed piezo-electric print head ganged up in a series of four heads that can fire droplets in three different sizes, which produce the high colour images resolution at a native 900dpi and balances this quality with efficient ink usage.

(Above & below) The printers can deploy high vibrancy colours to a wide range of media, making many applications possible

The inks are in a number of colours depending on the specification of machine. The basic printer has the standard four colour process set of cyan, yellow, magenta, and black with the top specification being eight colours adding a light cyan, magenta, and black, along with a white.

The True Vis inks themselves come in very handy 500cc pouches, pull out a small holder and you simply remove the discharged pouch and replace it with a new full one. In this day and age when there is an added need for traceability or compliance, these inks are underpinned by the Green Guard gold standard.

Green Guard certification is part of UL Environment’s ecological compliance program. UL Environment is part of Underwriters Laboratories (UL) and acquired Green Guard in 2011, which provides purchasers with assurances the products being supplied will comply with the highest of ecological standards.

To satisfy the Green Guard gold standard, the inks supplied by OKI must meet the stringent emissions standards based on established chemical exposure criteria. Specifically, the True Vis inks meet the UL2818 standard, which is for low chemical emissions for indoor production.

Speeds are impressive, high quality 900 x 600dpi four colour printing will be produced at up to 10.6sq m/h with eight passes, and billboard quality of 600 x 600dpi up to 34.7sq m/h with two passes of the print head. Should it be needed, the VG series can also be provided with an optional take up and dryer unit that will help greatly with the longer production runs.

Endless possibilities

That is the inks taken care off, so what types of production can be achieved with either the VG-640 or VG-540?

It is not just the vast number of materials that can be used with this printer/cutter, it is also the effects that can be achieved with this equipment. You can use the Roland printer to produce wayfinding signs helping people access all sorts of buildings and safety signs that can be exposed to the harshest of conditions.

The True Vis VG-640 is slightly more expensive coming in at 1,625mm (64”)

PVC-based media can be used for outdoor banners to make the drabbest of buildings colourful and attractive, with roller banners and pop-ups for any type of event or conference.

The printer can produce colourful images on adhesive films for covering all sorts of indoor and outdoor furniture, vehicles, and even floors. At the most extreme, should you wish to cover an aeroplane in exciting colours, the True Vis printer/cutter can even measure up to this challenge. Should a more tactile output be required, Roland’s print and cut technology can even produce sensory coverings and clear inks to produce braille effects. To be honest, looking through the specification list, it was very difficult to find a product outcome that this printer/cutter could not produce.

The printer can produce colourful images on adhesive films for covering all sorts of indoor and outdoor furniture, vehicles, and even floors”

When needed, the VG-640 or VG-540 can cut the final produce in one pass. Both printers come with a newly designed carriage and blade that has had an increased down force. This ensures much improved accuracy and a greater range of media that can be cut. The Roland software makes the nesting and cutting of the product as efficient as possible.

How do you operate this flexible printer? As you would expect there is a very interactive GUI panel that can control all aspects of the printer, regardless of what you are trying to produce. But there is yet another clever twist to these printers. You can actually check and operate the machine from any iOS or Android smartphone or tablet. You can make changes to production or alter machine operation whether you are either stood next to it or are at a distance from it.

In preparation for the print run, the True Vis printer uses the Versa Works Dual RIP and is included with a new core engine that improves previewing and has improved handling of PDF files. The RIP comes with embedded ICC profile support and variable printing data functions.

Should things go wrong, do not worry. Roland can supply remote support to have you back up and running as quickly as possible via the Roland On Support customer service. This service can send notifications on job progress, ink levels, and remotely tracks the printer status to ensure downtime is at a minimum.

So, if you have a customer base with an endless imagination, maybe the True Vis VG-640 or VG-540 can turn their wishes into reality.

Brian Sims, principal consultant, Metis Print Consultancy, www.metis-uk.eu

Your text here...