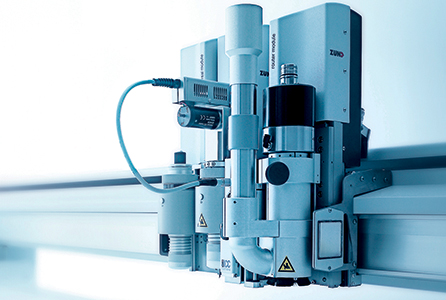

The Zund range of digital cutters has three lines—the D3, G3 (pictured), and S3

Some brands end up becoming the de facto name for anything of a similar type, for example, think of an excavator and most people will call it a JCB, whether it is yellow or not. Someone or something capable of many functions will often be described as a Swiss Army knife. This small tool offered in many configurations provides a solution for many tasks in one compact package.

It was in 1884 when Karl Elsener opened his knife-making business, which led to the development of the Swiss Army knife. Almost 100 years later, Karl Zund set up shop to distribute the range of Wild cutters. Two years later and the foundations were laid for what we now know as Zund digital cutters with the development of a range of peripherals for the Wild cutters, two years after that the products we know Zund for today were launched.

The new tooling was launched for the shoe industry and the first wholly designed Zund cutter was launched at the Paris Leather Show in 1989.

The first wholly designed Zund cutter was launched at the Paris Leather show in 1989”

The Zund range has three lines—the D3, G3, and S3 each offers distinct features but the central element to each is flexibility. The S3 is the baby of the range starting at 1,300 x 830mm. The G3 range is of particular interest to our industry and is available in a range of sizes from 1,330 x 1,600mm, all the way up to 3,200 x 3,200mm, with a vast array for configurations in between. Modularity is the key element of a Zund cutting system. If you pick the right size first off, you have yourself a production centre for life.

The G3 is available in sizes from 1330 x 1600mm, all the way up to 3200 x 3200mm

Array of tools

Zund offer an unrivalled array of tools for their digital cutters from oscillating tools for tricky to cut boards, carton, and leather foams, as well as the more common medias in the sign and display industries. It is no mistake that many high-tech industries with really high demands for accuracy boast a Zund cutter in their workflow.

It is for this reason that the company offers tooling capable of processing material such as carbon fibre and fibre glass etc. The key thing here though is that once you have selected the right size for your business, you will have one of the most versatile systems on the market.

The central element are the cutter modules and tools. The holder for these has remained the same size since the first machines were developed, meaning that if you only intend to cut display products or roll media when you first install your Zund, it is just a simple case of acquiring tooling as needs arise.

The central element of the G3 are the cutter modules and tools. The holder for these has remained the same size since the first machines were developed

With Zund’s commitment to ensuring that customers get a high return on investment, there is a good chance that, if kept well maintained, you will still be able to add tooling years later. In fact, I am told that there are very few updates that cannot be fitted to the oldest machines in service.

The Swiss have a reputation for high standards of engineering and the Zund is no exception. The cutters are sleek to look at and of robust construction. Moving parts are nicely concealed out of sight and importantly, out of the way of debris. There is also a separate podium housing the control centre, which uses Zund’s cut centre software.

The software can utilise files, form design programs such as Adobe Illustrator, allowing you to nest and organise jobs.

Gauging production time is an essential element of today's workflow and the cut centre does just that. Cut queue is the firm’s organisation software, taking out the hassle of manually arranging your work. It works seamlessly with your RIP, for example, by printing barcodes or QR codes, the cutter will recognise what job it has on the bed, adjust the cut file to suit, and select the cutter, all at the touch of a button.

The software has a database of material and will suggest the best tools for the job. All these features cut down operator time and provide the basis of an organised workflow, all of which helps to deliver a first class product to your client.

Clever features

One of the main tools of interest to sign-makers will be the router module. This clever bit of kit, in line with other manufacturers, will cut a wide range of ridged materials. And in the case of acrylic, you have at your disposal a finishing tool which will leave you with an edge close to a flame polished finish. The unit also has an on-board sensor which will scam the material on the bed and continually monitor the distance between the cutter and the face, and adjust the depth accordingly.

The bed of the machine is the usual vacuum type with independent zones, and the media is moved along on a belt. The belt moves to the front and in, and as the cutter progresses, the material moves to the front with the letters falling into a finishing area. Zund offers various options including table extensions, making it possible to process more material continually.

There are also loader systems for larger scale production, enabling almost unattended production. Obviously these are aimed at those with the need to process large volumes continually, but it illustrates just how flexible the system is, and importantly, how an initial investment can be upgraded without the need to completely reinvest in a new system.

All this Swiss high quality engineering does come at a price, but you are not looking here at something akin to a printer, with probably at best five years of trouble free use. With this product, you could potentially still be happily using your digital cutter ten, 15, or maybe 20 years later. With that lifespan, the purchase price starts to look more attractive.

With this product, you could potentially still be happily using your digital cutter ten, 15, or maybe 20 years later”

Factor in Zund’s commitment to ensuring that existing systems can be fitted with newer additions to the tooling line up and as a package it begins to make a lot of sense. Especially if you already have direct-to-board printing capabilities.

So there you go, the display industry’s answer to the Swiss Army knife. It will not fit in your pocket, but otherwise, it has a tool for just about every single job.

For more information on the issues discussed in this article you can contact Digital Print Innovations (UK) Tel: 01332 228150 or visit www.dpi-uk.com

Your text here...