Efficiency focus

While sign-making may be an age-old art that has withstood the test of time, the reality is that both new and developing technologies are changing the identity of the industry. Computers have had a major role in shaping the modern market, with sign-makers now able to call on a wide range of software to assist them with their work.

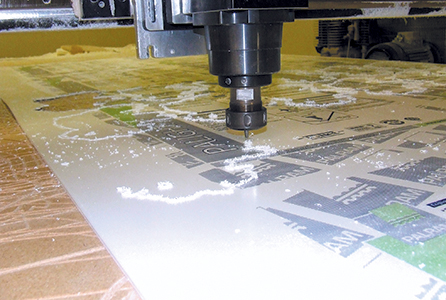

Many companies across the market use CAD/CAM software to assist them with certain types of work. This technology is particularly useful as not only can it help to boost the quality of work, but also overall efficiency in the production process.

Here, we look at some of the latest products and updates available to the market, and focus on how these offerings can help sign-making companies of all sizes to improve their business.

Access a larger market

One of the stand-out names in this sector is SAi, which has a wide selection of CAD/CAM products on offer to the market. EJ Nodurft, product director at SAi, talks about the importance of investing in quality software in order to ensure that you are producing the best work possible.

“The right choice of software for the applications undertaken is crucial to ensuring operational efficiency,” he says, adding: “Finding software that will allow sign-making businesses to address a wide range of applications, each of which is a potential revenue stream, will give them a bigger market.

The right choice of software for the applications undertaken is crucial to ensuring operational efficiency”

“It’s fair to say most programs have limitations of some type and understanding what they are before investing in one can make a huge difference.”

With this, Nodurft outlines SAi’s commitment to developing its own solutions in order to meet the demand of its customers. The company recently unveiled its EnRoute 6 CAD/CAM software, which Nodurft bills as its “go-to” product that is tailor-made for everyday cutting, nested-based production and creative design applications.

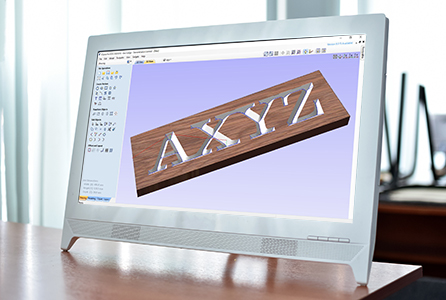

“A blend of artistic and precision drawing tools, coupled with an extraordinary toolpath engine, makes it the ideal software for 2D and 3D design and cut applications,” he says, adding: ”For CNC users, EnRoute 6 simplifies workflow, saves time and provides unique design capabilities to set them apart from the competition and increase profits.”

SAi’s EnRoute combines graphic design tools and the capability to create three axis CNC surfaces, which the company says makes it unique against other solutions

Also new from the company is SAi +EnRoute for Flexi, which, according to Nodurft, allows for faster and easier output of Flexi-designed 2D engravings and signage to CNC machines. This is an add-on to SAI’s flagship sign-making software, Flexi version 11 and 12.

Nodurft says: “Crucially, it allows sign businesses with a CNC machine and Flexi software to simplify the file clean-up and toolpath preparation of 2D or 2.5D Flexi design files for CNC output.”

Building on this, Nodurft outlines how SAi’s products differ to others available to the market: “EnRoute’s ability to combine both graphic design tools as well as the capability to create three axis CNC surfaces makes it unique against other solutions. It can also handle advanced nesting and toolpathing; no other single program offers all of these capabilities.

EnRoute from SAi is accessible via monthly or annual subscriptions, offering more cost control and flexibility for users

“It’s basically an all-in-one package that was created with ease-of-use in mind.”

Commit to investment

Phil Kneale, director of Graphtec GB, also appeals to sign-making companies to pay careful attention to investment in CAD/CAM software solutions. He says that this kit is just as important to production as hardware products.

Kneale explains: “As the intelligence source for and prime mover of all forms of CNC machinery, quality CAD/CAM software is a basic prerequisite for ensuring maximisation of workflow programs. However, all too frequently, it is treated as a virtual afterthought by many companies to the detriment of output quality and productivity levels. “

Graphtec GB offers the industry its own-brand Graphtec Pro Studio and Graphtec Pro Studio PLUS software programs. These are based on the widely specified FlexiSIGN family of software, developed by SAi, for which Graphtec GB has been a preferred business partner and exclusive UK and Ireland distributor of since 1989.

Graphtec GB offers its own-brand Graphtec Pro Studio and Graphtec Pro Studio PLUS software programs, both of which are based on FlexiSIGN from SAi

The company includes this software as part of the package on Graphtec cutting plotters and offers compatibility with over 30 different popular file formats, including key types AI, CMX, EPS and DXF.

Kneale says: “In addition to basic tool functions, the software provides more advanced options such as shape editing and auto trace and weld combined. Key features include automatic registration mark creation, tiling, an ability to create multiple copies of the same object for cutting, the addition of weed and border cut lines, tool assignment and condition settings, including cutting force and speed.”

Graphtec Pro Studio also supports the latest Version 6 of Graphtec’s proprietary Automatic Registration Mark Sensing system for optimum material alignment and cutting accuracy.

Kneale builds on this by highlighting the complementary Graphtec Pro Studio PLUS program, which he says provides additional and even more advanced tool functions for increased productivity. These include the ability to transform graphics and characters, enable automatic sequence numbering, bar code, QR and serialised number creation, power nesting and template production for rhinestone applications.

In addition, Kneale draws attention to Cutting Master, a plug-in software option for Adobe Illustrator and CorelDraw graphics suite and EnRoute V6 that provides 2D and 3D routing functions.

Kneale says: “Available in four different editions, comprising a suite of over 40 design and production tools, it is considered to be the most advanced software of its kind so far developed by SAi.”

Focus on quality

Robert Marshall, vice-president of market development at AXYZ International, also picks up on the importance of investing in quality CAD/CAM software by saying that this focus cannot be overstated.

Marshall expands: “Advances in software development invariably run parallel with those taking place on CNC machinery like routing, cutting and engraving systems that are used extensively in the sign and graphics and digital printing industries. Both are interdependent and neither can work to their true potential without the other.”

He leads on from this to give the example of dual reliability within the AXYZ PANELBuilder system. Marshall says this embodies a high-performance CNC router and specially developed software for processing large volumes of Aluminium Composite Material (ACM), which is used extensively in the sign industry.

Marshall says: “Over the past 12 years, there have been major advances in software development in terms of ease of use, more technically advanced tool functions and greater affordability that collectively have enabled much higher levels of productivity. As a result, the total cost of ownership of a routing/cutting system is much lower than hitherto, allowing an increasing number of companies to engage with CNC machining technology.”

AXYZ provides as standard the VCarve Pro and optional Aspire programs from VECTRIC. Both programs provide, in turn, all of the necessary tools for 2D and more advanced 3D functionality, and are fully compatible with the multi-stage Automatic Tool Change (ATC) systems on AXYZ and Pacer machines in the AXYZ portfolio.

Marshall bills VCarve Pro as the “complete solution for 2D work”, incorporating a number of advanced design and production tools. The program enables users to import and toolpath a single 3D model, as well as providing support to import multiple VECTRIC Clipart 3D models to create more advanced 3D constructions.

Available from AXYZ International, VCarve Pro enables users to import and toolpath a single 3D model, and also supports multiple imports of VECTRIC Clipart 3D models to create more advanced 3D constructions

Key features include the ability to process parts in excess of 600 x 600mm in size, a toolpath preview function that allows operatives to see how the parts will look when the routing or cutting process has been completed and true shape nesting for material optimisation.

Meanwhile, Marshall says Aspire is the easiest route by which users can progress from a 2D drawing to a high-definition 3D design and the subsequent creation of machine toolpaths.

In addition to all of the design and production tools provided by VCarve Pro, Aspire incorporates unique 3D construction tools that enable engagement with a wide range of applications beyond sign-making. These include wood-working, solid surface panel processing, engraving, milling and model-making.

O Factoid: An addition to sign-making, CAD/CAM software and technologies are used across various other industries, including dentistry. Here, the software is used to design and create prostheses such as crowns and veneers. O

The message from key suppliers here seems simple; ignore or under-invest in software at your own peril. Perhaps the products are not as glamorous as say a new cutter or even a wide-format printer, but the importance of the role that they play in the production process cannot be overestimated.

Quality software solutions grant you much greater control over production and allow you to iron out any creases before a design reaches the manufacturing stage. By doing this, you not only save time you would have spent going back to the start and producing the piece all over again, but also the costs associated with the wasted material that comes with it.

Commit to investment in quality software and take control of production.

Your text here...