A magical history tour

An overview of how sign design has changed and developed over the years inevitably brings up memories of traditional sign-writing, hand drawn visual designs, and manual operations. Fast forward through the decades and we have CAD design that includes 3D imaging, CNC machines, and a whole gamut of sophisticated technology and equipment—providing an ever-increasing range of opportunities for sign-makers.

Colin Pestell, managing director of GDI Trade Signs, gives the long view as he shares his personal journey into sign-making and reflects on the changes that have taken place over the past 42 years. Pestell’s introduction to the world of sign-making came through helping his father, Harry, a self-employed sign-writer and general sign-maker.

After being de-mobbed from the Royal Navy in 1946, and with no previous work experience or training to speak of, Harry decided to build on his skill as a moderately good artist and enrolled on a painter and decorator’s course at the Brixton School of Building.

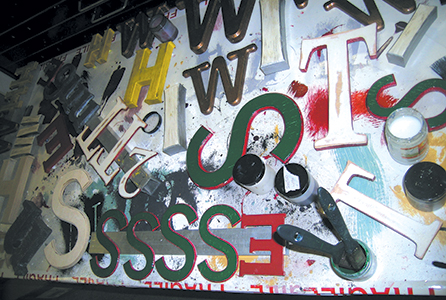

GDI Trade Signs’ montage reflects the manual and hand-crafted skills that were the essence of past sign-making techniques

“As well as gilding, wood graining and marbling, part of the curriculum was lettering,” says Pestell, who adds: “This was the start of my father’s career as a sign-writer.”

Almost inevitably, Pestell grew up helping his father where he could: painting boards ready for sign-writing, a bit of infilling, and learning how to use a brand new innovative process—‘wet transfer Letraset’.

“By the time I was 17, I knew exactly what I wanted to do when I left school—I wanted to be a sign-writer, like my dad. As I was a slightly rebellious teenager my father thought it better that I should attend college, rather than work as his apprentice,” Pestell reminisces, who adds: “So I ended up attending a three-year design course at South Bank Polytechnic.”

GDI Trade Signs’ colourful reception area is a visual history of sign-making from hand-crafted lettering to modern LED illuminated signage

However, all was not plain sailing for Pestell. The first year went well, but after that things went downhill.

“I found going down the pub and generally dossing around far more appealing,” he admits wryly, continuing: “The college eventually lost patience, and asked me to leave, and that left me with no grant, nothing to do and no income. The only thing I knew anything about was signs.”

So, taking a positive approach to the situation, in 1976 with the purchase of an ancient epidiascope, a polystyrene cutter, a jigsaw, and a very sharp scalpel, Graffiti Design International (GDI) was born.

Pestell recalls: “42 years ago, everything was hand drawn and hand cut. No computers, no CNC, no lasers. If you were lucky, you may have had a pantograph. At least Letraset had evolved into dry transfer lettering. The hidden benefit was there was very little to break down, but you had to have a good skills base to be a sign-maker.”

Eight years on, GDI was able to purchase one of the very early Gerber machines. Pestell explains the impact it had: “No more hand cutting Fablon with a scalpel. Two years further on, we bought our first 48 CNC machine—no more jig sawing acrylic sheet. We were on a roll.

GDI Trade Signs’ Colin Pestell says LEDs have been the single biggest influencing factor for his business in terms of opening up the horizons of creative design

“The introduction of computer technology made manufacture so much more efficient and consistent. However, it also opened up the industry to unskilled people, resulting in a plethora of poorly designed and made signs. What technology gives with one hand, it takes with the other. Obviously, the advent of digital printing had a major impact on the industry, and it could be viewed that it has spawned an entirely new industry. It certainly had a detrimental effect on screen printing, and again opened up the industry to more unskilled people.”

Commenting on the advent of the internet, Pestell emphasises: “It cannot be overestimated, but is often overlooked, how much impact the internet has had on all industry, and particularly our industry. The ability to transmit digital files all over the world for production and approval—a huge advance on fax machines and snail mail—and improving turnaround, production, and consistency.

“There are many more technological advances that could, and maybe should be mentioned. The list is quite extensive—thick coloured acrylics, letter bending machines, 3D printers, and so on. However, the introduction of LEDs to our industry is not something that can be ignored.”

He continues: “They are smaller, brighter, more efficient, and have greater longevity than almost any other form of illumination. The imaginative and innovative use of LEDs by sign-makers and designers is outstanding. Long gone are the days for the need of fluorescent tubes and the use of neon for encased lighting, although nothing quite matches the iconic look of exposed neon.”

I’ve thoroughly enjoyed seeing the changes to our industry over the last 50 years”

“I’ve thoroughly enjoyed seeing the changes to our industry over the last 50 years, some great and some not so great; and I’m really looking forward to witnessing the technological innovations to come.”

The way we were

Rolling back the years, I asked some of today’s leading sign-makers to describe what the industry was like before the advent of the plethora of technology and materials currently at their fingertips.

IS Group was first established in 1981 as a sole trader and the company was named Impact Signs.

“On the whole the sign industry was a craft industry with many small companies of trained sign-writers operating with a van, a mahlstick, sable brush, and a pot of sign-writing enamel paint,” reflects IS Group managing director, Jane Whitehouse.

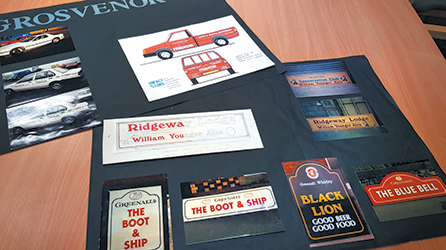

(Above & below) These examples from IS Group of hand drawn and coloured designs for presentation to clients demonstrate the painstaking craft and sign-writing skills of around 40 years ago

She continues: “Designs were sketched by hand with sign-writers having a select few favourite typefaces that were well practiced. It would take a considerable time to draw up a design and hand colour for presentation to a client. When chosen it would be reproduced on tracing paper outlined with chalk to mark out the design onto a vehicle or board for sign-writing.”When Astra Signs director Jo Derbyshire first joined the company, and the signage industry, in the late 1980s, it was a team of just four.

“At the time, our key skills ranged from sign-writing, poster writing, and screen printing to production of various types of letters from acrylic, polystyrene, timber, and aluminium, as well as making the back boards (mainly from timber), which were painstakingly hand-painted,” remembers Derbyshire.

Soon after, the company purchased a Graphix 4B vinyl and paper plotter, which is still proudly displayed in its reception area, providing a unique and interesting reminder of the company’s history and the industry’s progress over the years.

“All designs stemmed from sketching out on paper or reproducing a supplied logo,” Derbyshire continues, who adds: “Customers would come in and sit down whilst designs and fonts were discussed and agreed utilising Letraset books, moving onto next stage by either tracing, enlarging via a projector or free-handing again in more detail.”

Customers would come in and sit down whilst designs and fonts were discussed and agreed utilising Letraset books”

Sharing his thoughts on how the world of signage has changed over the past 20 or so years, Andy Simpson director of the Leeds centre of Fastsigns says that the main difference he has seen have been in external signage.

“Designing signs in the late 1990s was limited somewhat by the materials available to create durable external signs. Unless the sign was being painted, making a multi-coloured sign involved cutting vinyl on a plotter, which would then have to be layered to create the design,” details Simpson, he adds: “Furthermore, the inks in the early full colour printers did not have a great outdoor durability, which meant extra thought had to be put into the design.”

Moving on up

So how have the changes and developments of recent times altered the face of sign-making? Continuing on the theme of external signage, Simpson highlights the comparisons with today’s capabilities: “Developments in technology, materials, and processes over the years have allowed us to create much more detailed and intricate signage that is durable and will withstand the British weather. We can also print directly onto various substrates for both internal and external use, such as plywood, MDF, tiles, and so on, allowing us to be much more creative in the design process, at reasonable budgets. This has also made production quicker and allowed us to achieve much faster turnaround times.”

Indeed, when the Fastsigns Leeds centre first opened, its key piece of machinery was a 60cm wide vinyl plotter. “Now we are using flatbed printing and digital cutting machines that are the size of small rooms,” Simpson smiles, adding: “In fact, it’s such advancements in new technology and machinery that prompted us to refurbish our warehouse to create dedicated rooms for the Zund cutter and OCE UV printer.”

(Above & below) Andy Simpson, director of Fastsigns Leeds, explains that, unless a sign was being painted, making a multi-coloured sign in the 1990s involved cutting vinyl on a plotter, which would then have to be layered to create the design and was limited by the materials available

Reflecting on how these developments have influenced design, Simpson says that, over the years, the company has noticed that as signage technology develops, so too does consumer taste: “As a result, we are now finding that we increasingly have to produce more technically constructed and creative 3D signs that incorporate lighting elements into the design.

“Customers are also asking for traditional looking signs, which can be created with the new technology and substrates available. Twenty years ago, many of the requests we received were for basic signs on aluminium, PVC, and acrylic. Now we have a much wider range of substrates that we can choose from.”

With new developments, of course, come new opportunities, as Simpson recognises: “New technology and processes mean we can now complete jobs much faster and handle larger projects with ease. To rebrand 20 sites for a customer 20 years ago, for example, would have taken much longer, especially when considering logistics for signage creation and installation. Now signs can be created quickly and installed within a much shorter time frame.

“Advancements in our processes also mean we now have the ability to work with design agencies and be more creative. We’ve been working on some really exciting projects lately and one of the best parts about a new project is figuring out the most effective way to turn the design into a sign using the right materials.”

Speaking of how the designer’s job has changed, Simpson notes: “It’s physically easier to make signs now than in the past as a lot of the manual labour has been taken on by machinery. However, the learnings that come with new technology have changed the skills our team requires.

“Nevertheless, one thing that hasn’t changed is that designers must still have an appreciation of the materials available when creating designs based on the customer’s budget and materials available, as well as the technology that will have to be used to create them.”

Simpson concludes passionately: “It’s an exciting time to be working in signage, and I’m really looking forward to seeing what the future will hold as even more new technologies and methods enter the sector.”

Astra Signs’ subsequent growth and development is unmistakable. The current team of 58 full time staff is based in a purpose-built unit with all the machinery you would expect from a sign company in today’s market place: from CNC, welding, wet paint, and powder-coating processes, to all types of digital machinery, stitching, plotters, automated cutting tables, and automated letter making.

Taking digital print as an example, Derbyshire expands: “Design layouts and production methods today are heavily influenced by our in-house design and pre-press team, drawing on their knowledge and experience of different products, methods, and applications as well as their extensive training. Utilising various resources such as 3D software, CAD, Solid Works, Print Factory, and top of the range Mac computers, not only can we provide our customers with fantastic visual representations of their designs, but we can also send files directly to our print room and onto the machinery in one fluid transaction, safe in the knowledge that we will be producing accurate and high quality products time and time again.

“In today’s market place, it is imperative not only that we produce signage to a high standard, but that it is done promptly and efficiently. The technology we employ enables us to increase our productivity whilst maintaining quality and also remain competitive on price,” says Derbyshire.

IS Group’s Whitehouse also weighs in on how technology has impacted the sector’s make-up: “It was only with the advent of computers in the late ‘80s and the first vinyl cutting machines that the smaller companies were able to grow and take up more work due to the automation.

For the entrance to The Pinnacle in Manchester, IS Group was asked to create a bespoke canopy structure to adorn the entrance of the building. The finished installation included very intricately designed illuminated acrylic fins and a canopy illuminated with Sloan-LED lighting

“Now sign companies are able to challenge for a diversity of work be it digital printing, hoarding, signage roll outs, retail park totems, and shopping centre lighting features, due to the advancing technology of CNC routers, laser cutter engravers, flat bed printers, and advances in materials.”

However, Whitehouse points out that with the technology has come the requirement for sign companies to invest in training and adherence to new legislation such as BSEN1090-2 for structural steelwork and increasing legislation in health, safety, and the environment.

Whitehouse explains the impact of this on sign companies: “All of the advances in technology and legislation have to be taken into account by the designer, utilising the best material for a given project, sheet size, welding points, structural calculations weight for installation or delivery and future maintenance. Although the possibilities are now endless, it becomes inevitable that many projects are prototypes, as they have not been designed or built before.

“However, IS Group has invested in the future and with our commitment to Investors in People, our staff are well placed to adapt to the future skill and technology enhancements that this developing industry might bring.”

The entrance to The Pinnacle building, a luxury living space and high-quality offices, located in the heart of Manchester’s business district is an example of the projects for which IS Group is commissioned.

The company was asked to technically design and create a bespoke canopy structure to adorn the entrance of the building. The project demanded high production values and innovation to reflect the prestigious building’s image and its fashionable location.

IS Group’s design team worked both in its studio in North Wales and on site to create a bespoke canopy to replace the existing metal structure, in line with the building’s modern, stylish, and international theme.

CAD renders were used to ensure that the project met the client’s exact design requirements. IS Group’s solution included intricately designed illuminated acrylic fins; specialist iron patina paint finish for a luxurious look; and black anodised aluminium cladding. The canopy was illuminated with Sloan-LED lighting, in addition to a special overhead light-well built into the structure, which allows natural light to flow through it.

Looking at the pros and cons of change, Sign of the Times managing director, Darren Roughton remarks: “It never ceases to amaze us how rapidly an investment in the latest industry technique or machinery becomes last year’s news. It seems that advances in the industry happen on a daily basis but to be fair, these advancements are now allowing us to achieve what was formerly the impossible, and that can’t be a bad thing for anyone.”

Signage manufacturers now have the ability to be more creative than ever before”

He adds: “There is nothing more satisfying for us than being presented with the most creative of briefs and having the tools and knowledge in-house to deliver the very best and most innovative of solutions. We’ve come a long way since we were working with paint and stencils.

“Continual investment in the latest technology ensures we can offer the very best, most cost-effective, and creative solutions for customers. Our Zund for example, with its I-cut Vision System allows us to cut media to the most finite of detail, achieve volume quickly and precisely, and therefore reduce costs.”

Roughton also believes that an awareness of digital signage solutions is a key development for Sign of the Times, and one that is becoming more of a pre-requisite: “Offering clients the ability to control and interact with their signage/display via IT or even having the displays respond intelligently to external sources such as the weather, is something we have had to be able to respond to. For them to effectively compete within their industry, we have to take the lead in ours.”

Continual investment in the latest technology ensures that Sign of the Times can offer the very best, most cost-effective, and creative solutions for its customers. The company’s CNC machines can cut anything from wood to aluminium faster than ever before

These developments in new technology and process have expanded the company’s client base over the years so that it now includes a higher percentage of design houses, looking for the production of art installations and bespoke displays in particular.

“As we can now offer much more than fascia lettering, a whole new market has opened up for us. It’s an exciting time,” enthuses Roughton.

The shape of things to come

Turning to the ever growing interactive digital signage sector, Joanne Turner, head of marketing at in-store technology and queue control specialist Tensator, echoes Simpson’s previous comments on the correlation between technological advances and customer demand: “In addition to significant advances in technology over the past two decades, the rising expectations and demands of customers and passengers has forced the signage industry to become more innovative in order to attract attention and engage the public.”

Tensator’s Virtual Assistant (VA) interactive signage for Network Rail at London’s Kings Cross Station is an example of the technology now being used to engage and inform members of the public as people become increasingly more responsive to digital signage than to traditional static signage

She further notes that the continuing development of portable devices, including smartphones, tablets, and, more recently, smart watches, has led to people paying less attention to their surroundings, thus creating a challenge for sign-makers and marketers alike.

“However, new technology has also paved the way for new methods of design, with traditional printed signage now being just one of many options for businesses to market their products, or for facilities managers to alert members of the public when it comes to wayfinding or the signposting of hazards,” says Turner.

Indeed, research conducted by Intel found that digital signage captures 400 percent more views compared to traditional static signage.

“In fact, it is increasingly obvious that in a world hyper-connected with screens via laptops, mobile phones, and tablets, we have become a little desensitised to billboard displays and stickers. How many of us, for example, notice important information such as fire exit signs in our offices, which are present in every working day of our lives?” asks Turner, who adds: “As such, in-store technology such as the Tensator Virtual Assistant (VA) has been crucial in driving consumer engagement in including retail promotions.”

For example, Grafton Shopping Centre in Cambridge became the first in the UK to utilise this technology. Used in conjunction with one of the centre’s major restaurants Bella Italia, the VA informed consumers how to claim 20 percent off their food bill, receiving 100 redemptions against a typical 10 percent follow-through rate. That means around 1,000 customers effectively engaged with the Virtual Assistant over the promotional period, increasing traffic and boosting sales in the process.

O Factoid: Roman signboards were usually made from stone or terracotta. Alternatively, they were whitened areas, known as ‘albums’ on the outer walls of shops, forums, and marketplaces (Wikipedia) O

Interactive signage also has the ability to bring about behavioural change. Similar technology, designed to inform airport passengers about prohibited items in hand luggage, were installed at the entrance point of security within a number UK major airports. The VA can be used to aid an airport’s check in and security process by informing passengers about acceptable liquids and other security processes. For various sites, it has led to a reduction in bag rejections, meaning fewer delays through the security process—particularly crucial in times of high traffic.

“With new technology including AI and VR continuing to emerge all the time, signage manufacturers now have the ability to be more creative than ever before, with new ways to influence behaviour and reinforce a brand’s message. It will be interesting to see how immersive the customer experience will eventually become—it’s a very different ball game to the techniques used 20 years ago,” concludes Turner.

Interesting indeed and, with the massive changes that have taken us from paint brushes and pencils to LED illuminated and digital interactive signage over the past 50 years at an ever-increasing pace, I wonder what opportunities are on the horizon for the future of sign design?

Your text here...