Making their mark

Etching became popular during the sixteenth century, evolving from fifteenth century techniques for creating patterns on swords. Armourers would cover new swords with wax, then scratch through the wax and put the sword in a weak acid until the acid bit a line in the metal.

Both etching and engraving remained very much a manual operation for several centuries, with pneumatically operated tools being introduced during the mid-1900s. Whilst manual techniques continue to be used for specific art and craft applications, the development of CNC machines has opened up etching and engraving opportunities to a whole gamut of industries—sign-making not being the least among them, with laser engravers increasingly becoming the products of choice.

There are two sides to this story though, as many sign-makers still opt to use trade service providers for their etching and engraving needs due to the higher levels of technical competence needed in comparison to sign production techniques such as wide-format inkjet printing for instance. This is especially true of chemical etching, and there are some serious points that sign-makers need to weigh up if they are considering installing their own equipment.

Colin Edge is managing director of Multitechnic, specialist suppliers of chemical etching services to the sign industry, and he makes some salient points in this regard: “If you imagine that an etching machine will easily make you etched signs, you need to be aware of what is involved. You can’t just feed artwork in at one end and get etched plates out at the other, indeed an etching machine is nothing more than a plastic box with a heater and a pump to spray acid onto a piece of metal. It is only a very small part of the whole process.

“You cannot just feed artwork in at one end and get etched plates out at the other,” states Colin Edge, managing director of Multitechnic

“Most importantly, do you have somewhere to put an etching machine? It is basically a vat of quite hot acidic solution, which gives off lots of acidic vapours, which unless properly extracted will start to destroy every bit of metal equipment in that part of the building. Ideally it should be in its own wet room with sinks and a floor that can be hosed down, as emptying and filling the machine can be a messy business.” Maintenance and down-time costs are quite high too explains Edge, as the acidic environment slowly destroys machine components. Another important factor to note is that you cannot just wash acids down the drain, as they need to be disposed of properly and should be recycled. You also need to understand the chemistry, as different metals require different etching conditions. Get it wrong and your plates will not etch, or even worse, you could have dangerous fumes pouring into your workplace, and overheated acids that will burst your machine open, dumping a large amount of hot acids onto your floor.

Edge continues: “Etched signs need to have paint fill to add colour. When you etch metals, the acid eats sideways as well as down. If you etch deep enough to make the filling easy, the etched image becomes a blurred mess. Painting a properly etched sign is a skilled job. You need to use the right paints, and if your etching chemistry has not produced the right quality of image, your paint will not adhere to the metal properly and will eventually peel out.

“Before you etch anything, you need to apply an etching stencil to the metal. You can etch crude designs using vinyl, but to reproduce the detailed and fine quality images that people expect from etching, you need to use a photographic stencil of some sort, which means more chemistry and equipment, and may require a dark room.”

In addition, Edge explains you need to be able to cut and drill metal sheet to the right quality, and very few sign-makers have the equipment to do this. You need a stock of different metals in a variety of thicknesses and finishes, which takes up space, and you need to know how to handle sheets of metal safely and without damaging them.

Edge concludes: “Not surprisingly, few people consider it worthwhile investing in the huge amount of equipment, training health and safety, and learning required to manufacture chemically etched signs, and instead use a good quality specialist.

“We have seen a few customers buy their own etching machines over the years, and all of the ones that we know of have ended up scrapping them. It may sound like a tempting idea, and the people who want to sell the machines obviously make it sound a lot easier than it really is. Even the biggest of these customers was only buying maybe £40,000 per year etched product from us, and at that sort of level there is no way that you can make them yourself more cheaply than we can sell them. We work extremely efficiently, we have to as we need to make larger jobs such as apartment or hotel schemes in just a few days, and that level of efficiency means that we can sell finished signs for less than it would cost to make them on a much smaller scale.”

Making the right choice

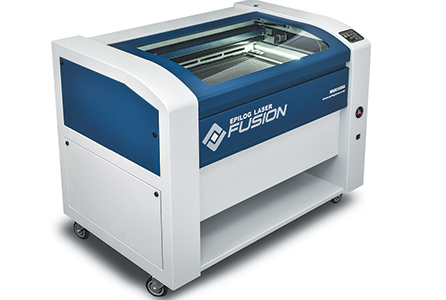

Moving on to engraving systems, and Epilog Laser, based in Clevedon, North Somerset, has been producing laser engravers since 1988 and currently has over 30,000 lasers in service worldwide. Over recent years the company has identified a trend that is seeing engravers turning increasingly to laser technology as a solution, as requirements become more detailed.

“Laser machines are cleaner, safer, quicker, and more flexible than traditional etching methods,” states Epilog’s marketing manager, William Stafford.

He goes on to explain that the type of laser you require will be governed by the range of materials you wish to mark, the type of mark that is needed, and the volume products you are producing. Stafford also provides a useful comparison of the distinct types of laser engravers available: “Co2 lasers have and continue to be the weapon of choice for many sign shops due in part to the range of sizes and wattages available, but mostly because they can convert a wide variety of materials from paper and card to plastic, wood, and glass,” Stafford adds: “However, when it comes to metals they can be somewhat limited. It is possible to get a good surface mark on anodised aluminium and painted metals, but to obtain a mark on others such as stainless the surface must be pre-treated with a metal-marking compound such as Cermark or Thermark. Though all marks created by a Co2 laser will be by their nature a ‘surface mark’ rather than a deep etch.”

Epilog Laser’s William Stafford explains fibre lasers operate on a totally different wave length to that of Co2

Stafford continues: “On the other hand, fibre lasers operate on a totally different wave length to that of Co2 (Co2 = 10,600nm/Fibre =1,600). Also, several types of finished mark can be achieved using a combination of laser tube and focus settings from light polished to annealed and deep etched marks.”

Stafford believes that the ideal situation for sign shops is to have both laser sources (Co2 and fibre) available, and Epilog has achieved this with the Fusion M2 range. These machines are currently available in two sizes 32 x 20” (81.3 x 50.8cm) and 40 x 28” (101.6 x 71.12cm) which can be supplied as Co2 only, fibre only, or as dual source with both. The Fusion range also features a ‘flying optics’ system to guide the beam path to the engraving area to deliver a variety of etched marks and finishes.

HPC Laser’s range of machines, such as the Co2 Laserscript engraver, provide a fast and efficient method of putting scribe lines or dots on acrylic

“If high speed and volume are required, then a Galvo laser system may be more suitable,” recommends Stafford.

The G2 Galvo laser system from Epilog uses a fibre source but the lens is fixed, and the beam is guided to the point of contact by a series of oscillating mirrors, which makes the process much faster. Utilising a unique dynamic-focus lens technology, the G2 offers engraving areas of 4 x 4” (10.1 x 10.1cm) up to 24 x 24” (60.9 x 60.9cm) and can produce a wide range of marks including deep engraving.

Fast and efficient

Halifax-based HPC Laser has also found the sign-making market to be experiencing increased growth in the laser industry.

Sales manager, Oliver Carter expands: “HPC offers professional laser machines at affordable prices, and many of our customers are choosing to purchase a laser to increase lead times rather than outsourcing. Lasers offer personalisation throughout signage, including company logos, brand image, exhibitions, point-of -sale, and window displays. They provide a fast and efficient method of putting scribe lines or dots on acrylic, which allows laser cut panels and letters to illuminate evenly when illuminated from the sides.

“Owning a laser machine will not only improve performance, it will boost productivity and save you time and money. In terms of plastics, the polished edge from a laser cuts out time and labour-intensive processes,” observes Carter.

In terms of plastics, the polished edge from a laser cuts out time and labour intensive processes”

HPC Laser now also offers fibre laser machines from 300w to 3kw capable of cutting sheets of metal up to 10mm. “Fibre lasers can be used for the processing of stainless steel, mild steel, alloy steel, copper, aluminium, gold, silver etc. and are widely used in the production of advertising boards, textile machinery parts, kitchen utensils, car machinery, electric parts, plus many more,” Carter adds.

He concludes: “Our trained engineers have over 50 years’ combined experience in the laser industry and can provide full set-up, installation, and training to help get you started. We hold stock of over 100 machines in our Yorkshire warehouse, and have a large 200sq ft showroom so you can try before you buy.”

Customer-led innovation

From laser engraving wood and leather to laser engraving glass with a rotary attachment, the application options offered by Trotec laser machines are wide ranging.

Trotec was formed in 1997 from a research branch of Trodat and has since become a world leader in the field of laser technology and laser manufacturing. As part of the Trodat Trotec Group, Trotec develops, manufactures, and markets laser systems for marking, cutting, and engraving, as well as the manufacture and supply of a range of engraving materials. Serving customers in more than 90 countries, and with over 500 employees worldwide, Upper Austrian-based Trotec Laser relies on the ongoing expansion of its technological lead and customer orientation.

A prime example of the company’s innovation, and a product that attracted much attention at the recent Trophex Exhibition, is its Speedy Laser Engraver. The Speedy series laser engraving machine is suitable for both start-up businesses and those who want to speed up production. The machines require minimal maintenance, while the patented Inpack Technology reportedly provides the ‘longest laser lifetime available in the market’.

Available as a Co2 laser engraver, fibre laser engraver, or a Flexx laser, the Speedy laser engraver series is 100 percent designed and manufactured in Austria. Meanwhile, the Speedy 300 Flexx features both Co2 and fibre laser sources, which allows a wide range of materials including acrylic, stone, wood, and stainless steel to be processed in a single job.

One satisfied user of Trotec laser engravers is Cheltenham-based print and gift company Betsy Benn. The company chose Trotec to personalise a variety of their designs, from Christmas decorations to passport covers and beyond.

(Above & below) This personalised destination framed print, designed and created by print and gift company Betsy Benn was produced using a Trotec Speedy 300 laser engraver. Betsy Benn, created the personalised Christmas tree decoration using the same machine

Company director Betsy Benn started out as a sole trader in 2010 focusing on selling her unique prints in small boutiques. The purchase of a desktop laser cutter in 2014 enabled Benn to take the artistry she had developed and apply it to new materials, taking the company in new and exciting directions.

Once the processing capabilities of laser technology became clear, Benn sought a larger and more powerful machine to improve the company’s workflow, opting for a Trotec Speedy 300 laser engraver, which was installed in 2016.

Benn says: “Our Speedy laser machine has added another dimension to our work and is an important element of the creative process when building new ideas, offering greater creative scope to process a variety of materials.”

Betsy Benn’s range of gifts incorporates a variety of different materials from wood and acrylics to paper and fabrics, with a diverse product portfolio which includes custom designed prints, greetings cards, and decorations.

As well as the Speedy 300’s processing capabilities, the customer support and after sale service were also important in helping Benn to decide which laser machine supplier to choose.

“The ability to go into Trotec’s laser machine showroom to test the machines and find out what was possible on our own products, coupled with Trotec’s experts being on hand to advise us, made us feel confident in our purchase,” explains Benn, who adds: “In addition, Trotec’s after-sales support is excellent. Whether a technical support issue or simply needing some advice, Trotec is always happy to help me.”

Wide ranging options

Other companies offering a wide range of small and large engraving machines include CTR Lasers and Gravograph. With headquarters in Northamptonshire, CTR Lasers has been distributing laser machines in the UK markets since 2004, and in 2012 the company progressed into UK manufacture for its British designed laser cutting systems and engraving machines, increasing floor space by 25 percent, while retaining its sizeable customer demonstration area.

In 2016 CTR re-designed its TMX range of laser machines (with work areas ranging from 650 x 420mm to 1,200 x 900mm) to increase the speed of manufacture and reduce the materials used in the frame, which the company claims offer a high quality product at a new, lower price.

CTR Laser has been producing laser-based technology for many years and the laser engraving machines produced by the company continue to be among their most popular items. Indeed, its laser cutting machines are capable of engraving a wide range of materials to a high degree of accuracy, and even intricate or complex detail can be produced effectively.

In 2016 CTR re-designed its TMX range of laser machines to increase the speed of manufacture and reduce the materials used in the frame

Machines can be customised for specific industrial or educational applications and can easily be adjusted for a wide range of materials, making them ideal for bespoke designs, jewellery, glass, acrylic, and wood engraving, as well as architectural models and prototypes and education projects.

During the most recent series of open day events at its Leamington Spa site, Gravograph introduced the new LS100 Edge as well as demonstrating other engraving machines, including the compact M20.

O Factoid: The first evidence for humans engraving patterns is a chiselled shell, dating back between 540,000 and 430,000 years, from Trinil, in Java, Indonesia, where the first homo erectus remains were discovered O

This new range of machines has been designed with ease of use at the forefront, with a user-friendly interface and wide range of features to make the task of engraving less of a challenge. The LS100 and LS100EX are rugged Co2 lasers and can be set up in a factory, workshop, office, or retail outlet, and the LS100 can tackle engraving laminate, traffolyte, wood, glass, rubber, anodised aluminium, and even stainless steel.

Gravograph’s M20 Energy engraving machine, launched in October last year, is also proving a very popular choice.

It is one of the lightest and smallest machines in Gravograph’s range. With its compact design and just 10kg in weight, this machine can be easily moved for use at fairs or events. It is suitable for personalisation of small objects, such as pens, lighter, engraving on jewels, medals, watches, marking of manufacturer’s plates and engraving on cutlery and giftware.

(Above & below) Gravograph’s technology is designed to accommodate a highly-diverse range of substrates without any loss in accuracy or the need for further finishing

Whether you are already offering an etching and engraving service or looking to add it to your portfolio, there is clearly plenty of choice of equipment out there, not only for the established practitioner but for ‘beginners’ too. The great thing is that there is also plenty of opportunity to get ‘up close and personal’ before deciding which option is right for your proposed range of materials and applications—or even to help you decide on a new direction.

Your text here...