Super-sized ambition

The development of super-wide or grand-format printers is rather like Topsy—it ‘just growed and growed’. A combination of market demand for wider and larger-format print and the evolution of new materials has resulted in the need for ever wider printers, with super-wide-format starting at around 2.5m and now reaching widths of around 5m.

John de la Roche, national sales manager at Hybrid Services, provides the backdrop: “The super-wide arena offers more and more opportunities across all sectors as print continues to increase in size,” says De la Roche.

He adds: “The development of technical textile materials has opened up applications like building wraps and long-drop exhibition graphics, creating tactile and durable graphics. It’s big business and attracts lucrative contracts for any sign and graphics provider investing in this size technology.”

The super-wide arena offers more and more opportunities across all sectors as print continues to increase in size”

Feel the width

To get a feel for what is currently available and some of the new developments and latest innovations in the super-wide sector, I asked four of the key players to provide an overview.

Mimaki’s offering in the super-wide-format market includes the UJV55-320, 3.2m roll fed UV printer, which, according to De la Roche, makes light work of textile printing for exhibition and retail graphics, especially backlit applications that require high quality and vivid colour prints.

De la Roche continues: “Mimaki has an excellent reputation for listening to its customers and delivering the machines they’re asking for, and this results in products like the UJV55 coming to market.

“Mimaki’s UJV55-320 is an ideal choice for sign-makers looking to invest in grand-format hardware because it uses Mimaki’s latest flexible LED UV ink to produce banners, backlit, and point-of-sale graphics at up to 3.2m wide.”

With all the benefits of LED curing, including low running costs, the printer also features the option to run two narrower rolls concurrently, an inline lightbox for checking backlit output on the machine, and the capability to run roll media up to 100kg in weight.

Another world-leading manufacturer of advanced digital production technologies is Durst, which constantly launches new products and services.

O Factoid: The poster for the 2016 movie Boss, printed on seemee mesh extra, set a new Guinness World Record, beating the previous record by more than six times. The world-record poster consists of 36 panels (5m by 18 sections) and was registered officially in the Guinness Book of World Records measuring 58.87 x 54.94m. O

“This year we’ve announced some major steps forward with our technologies, all welcomed by our customers who say it’s the consistency, productivity, and profitability that makes us stand out from the crowd,” states Peter Bray, managing director of Durst UK and Ireland.

Over the past twelve months, Durst has unveiled follow on ‘plus’ versions to its commercially successful Rho P10 250 HS and Rho 512R printing systems, offering significant advantages in productivity and economy with new features and enhancements. They also benefit from new service options, including extended warranty periods, and new virtual support, and analytics functions. The company has also launched new FLT, high flexible inks, which enable customers to produce soft signage systems.

“New developments in strategic components of Durst’s proprietary hardware and software have led to the Smart4 revolutionary technology that boosts the Rho 1312 productivity up to 1.000 m2/h (330 boards/h) in two-pass production mode,” Bray remarks.

.jpg)

New developments in strategic components of Durst’s proprietary hardware and software have let to the Smart4 technology that boosts the productivity of the Rho 1312 up to 1.000m2/h

Other new features include a double-sided, roll-to-roll option to print rolls front to back accurately, a new ‘true white’ option to print white as a layer in one process and for day and night applications, and an ink-saver new feature to create standardised profiles to reduce ink consumption up to 35 percent.

A further development of the successful P10 series is an ink-saver function, which offers 40 percent greater productivity. It also offers an advanced application for hapt printing and roll-to-roll double-sided printing.

“The new Rhotex 325, specifically of interest for soft signage, and the Rho WT (Water Technology) 250 printing systems have also been showcased; but we appreciate that, for many sign-makers, water technology is still in its infancy,” adds Bray.

One new development that EFI’s customers have found particularly successful is the new range of roll-to-roll LED inkjet printers—the EFI VUTEk 3r and 5r, which come in 3m and 5m widths. EFI claims that these printers are the fastest in their class, with speeds up to up to 4,896sq ft per hour combined with best-in-class quality.

“And with the throughput they offer, the printers have lower total cost of ownership compared with other, similar roll-to-roll devices,” emphasises Ken Hanulec, vice president of marketing of EFI Inkjet.

Hanulec continues: “The other big development we have seen in super-wide- format is the migration to soft signage. Growth in soft signage has accelerated significantly, particularly in the retail POP and exhibition/trade show graphics sectors. We are meeting demand for larger graphics and higher throughput in soft signage with a 5.2m version of our VUTEk Fabri VU series of aqueous dye-sublimation printers; and we are seeing increased demand for our Reggiani Pro soft signage printers, which are intended for businesses that maybe started out with a Fabri VU and have built up enough dedicated soft signage work to need a higher-volume dedicated device.”

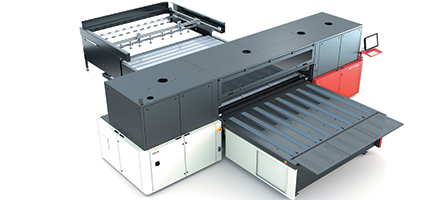

Agfa Graphics made the transition to LED UV curing technology with the successful Anapurna range of hybrid and dedicated flatbed presses, launched at Drupa in 2016.

The Agfa Anapurna H3200i LED high speed hybrid printer, first seen at Drupa in 2016

“Since the introduction of the very latest and energy efficient air-cooled LED lamps, Agfa has also included LED to the mid- to high-end Jeti Mira and Tauro H2500 range, again allowing for increased levels of cost savings and productivity enhancements,” expands Steve Collins, product marketing and channel manager of Agfa UK/Eire.

(Above and below) A major advantage on Agfa’s Jeti Tauro H2500LED is the ability to automate the loading and unloading process to maximise productivity

“Secondly, when combining LED curing with our Agfa made UV inks, Agfa can produce a low level of ink consumption with our thin ink layer technology. This is possible because Agfa understands all three of the main components of the inkjet process, the print heads, UV curing and, of course, the inks,” Collins affirms.

See the difference

So that is the technology, but what in particular makes these machines stand out from the crowd and how can they help sign-makers stay ahead of their game?

“Our roll-to-roll super-wide-format printers stand out on a number of counts,” maintains Hanulec, adding: “First they have our proven, versatile cool cure LED imaging, which gives customers a broader range of substrate choices. Our LED technology is also very consistent with curing, which means fewer wasted prints, and they use significantly less power than traditional UV or latex printers, which means our customers have lower operating costs as well.

“On top of that, we’ve provided a range of world-class finishing and material handling automation options for these printers that give customers the ability to achieve turnkey production in high-volume environments. Inline roll-to-sheet cutting, slitters, and a sheet collector kit reduce, or eliminate altogether, the need to handle printed jobs on separate finishing tables. We also offer optional features for automated double-sided backlit and block-out printing; a mobile app for remote printer monitoring and more.”

Hanulec adds that EFI’s soft signage Vutek Fabri VU super-wide-format printers also stand out for their speed.

EFI’s Fabri VU printers are particularly noted for their speed, with the ability to print up to 4440sq m/h on the 5.2m model

“You can print up to 446sq m/h on our 5.2m version, but in addition to that is the quality. Beyond the fact that they run up to 2,400dpi, the printers also have the same proven imaging technology developed for leading apparel and décor brands in industrial textile printing with EFI Reggiani printers,” elaborates Hanulec, adding: “Plus, unlike other soft signage printers, the Fabri VU models can run direct-to-fabric or on transfer paper without changing ink sets, which creates tremendous time savings in terms of machine down-time.”

Hanulec further comments that the benefits and opportunities with EFI’s Vutek 3r and 5r LED roll-to-roll printers really come from higher throughput and a lower total cost of ownership.

“In some cases we are hearing these printers are light years ahead of the equipment they replaced,” observes Hanulec.

Agfa’s Collins notes that diversification is a big topic for today’s print companies, and finding new and innovative ways to make money is a major factor.

Collins elaborates: “Today’s super-wide inkjet presses allow for special effects over and above the everyday requirements for indoor/outdoor signage and point-of-sale. The creation of elevated/textured printing with white ink, printing varnish to create a 3D effect as well as cosmetically pleasing results and using new and different types of innovative substrates, allows for printers to step into new markets and of course create new revenue streams for their business.”

He adds: “Another major advantage is the ability on our Jeti Tauro H2500LED to automate the loading and unloading process to maximise productivity.

Maximising your investment at this level is a key driver for companies looking to grow their business”

“In addition, 3/4 automation is an available option, allowing for reduction in down-time on the manual aspect of loading and unloading rigid sheets, which can not only be time consuming but in some cases wasteful. Maximising your investment at this level is a key driver for companies looking to grow their business.”

Taste the success

The proof of the pudding is in the eating, as the saying goes, and so it is with machinery and technology. RMC Digital Print and Béflex are two companies that have tried and tested some of the super-wide-format printers highlighted here.

Investment in a new Durst Rho P10 inkjet printer system to ramp up capacity and further improve quality was at the heart of a £1m expansion programme for £2.5m turnover trade printer RMC Digital Print in Hull. Established in 2010, 70 percent of RMC’s work is for sign companies and the remainder for exhibition businesses.

The company uses Durst equipment for every test sample sent to customers and, these days, with turnaround times being extremely tight, RMC says that the Durst is critical to achieving customer requirements.

Nicole Spencer, operations director at RMC Digital Print, comments: “The quality on the Durst is the best I have ever seen. We have been hugely impressed. The other machines just don’t get near. And Durst is an extremely professional organisation in every aspect.”

Nicole Spencer, operations director at RMC, is impressed with the quality on the Durst Rho P10 inkjet printer

Hungarian company Béflex offers a wide range of products for its customers, not only in Hungary but Europe-wide. And it was the first European company to install EFI’s 5m-wide VUTEk 5r LED roll-to-roll printer.

“Béflex reported that it is faster than its previous 5m printer and offers better image quality; on top of that, they found that the printer uses half the ink and energy of the one that it replaced,” relates Hanulec, adding: “And with that type of savings, Béflex’s executives estimate that they will have as much as a five year head start on competitors in terms of being efficient and cost-competitive in the market.”

With an increasing market demand for extra large-format graphics, these giants of the graphics and sign-making industry certainly come into their own in opening up a whole new range of options to diversify and generate new business avenues. There are significant benefits in productivity, turnaround times, and cost savings to be had along the way too.

Your text here...