Dive into a new sign dimension

Keeping ahead of the game in today's fast moving world of technology is no mean feat. The day you feel like you have finally worked out how to use all the functions on your smartphone is inevitably the day the next model is announced, leaving your old one technologically inferior and you with the sensation that everyone else is moving on to bigger, brighter—and hopefully more scratch-proof—things.

This progressive escalator seems to be perpetually skywards-bound, and businesses as well as individuals can often suffer from this technological FOMO (fear of missing out). This is particularly prevalent in the world of computer software which, along with the jargon and unhelpful abbreviations, seem to change and develop at a rate of knots.

The arch enemy of FOMO is time. While FOMO creates the illusion that time is finite and a decision needs to be made fast, the best thing to do is to face it, take a step back, and review what the various options are. This way, your decision comes not from hearing about the latest fad and jumping on it before anyone else, but from considering your business's needs and seeing what option suits you best.

This is very much the ethos of Vectric software, which according to its commercial director James Booth, is designed to make cutting parts on a CNC an “enjoyable and productive experience.”

Booth continues: “The combination of power and simplicity lets you efficiently generate or manage your design, then quickly create precise toolpaths to drive your CNC. We back this up with a friendly and knowledgeable community of staff and customers, who provide a user-experience that we believe is second to none.

“If you are buying, building or already own a CNC machine then please browse around our website to learn more about how we can help you to get the results you want. We think the best way to prove how good our programs are is to let you try them, so we offer free trial software, training videos and files for download. We also recommend visiting our vibrant online user forum, where you can ask questions and see what other ‘Vectricians’ are making.”

Expert advice

Vectric has also cleverly designed its software packages to scale to the users requirements, and as such offers Cut 2D Desktop, Cut 2D Pro, V Carve Desktop, V Carve Pro, Aspire, Cut 3D, and Photo V Carve. From these Aspire is its flagship all singing and dancing solution, and has been the force behind many award winning and nationally

celebrated signage projects.

Vectric users share best practice, tips, and tricks with each other via its online user group to help improve each others work

The company’s determination to help current and prospective customers really understand what software platform will be best for them is embodied by its annual User Group Meeting, which will next be held at its new office in Alcester, Warwickshire on the September 28th.

“This will be a single day event with a strong focus on our Aspire software, with a few of the sessions also being relevant to V Carve users,” explains Booth, who adds: “As with our two previous UK meetings this will be a condensed version of the User Group meeting we are holding in the US in October. This full day of presentations and classes is designed to share information about the latest features along with tips and techniques to get the most from your software.

“As well as the opportunity to learn from the Vectric staff, the meeting gives like-minded CNC enthusiasts and professionals a great excuse to meet up, share knowledge and discuss their work.

“As the meeting is being held at our office this year you will also have a unique oportunity to meet Vectric staff, see our workshop (Vectric Labs) and look at all the samples of work we have on display. There will also be lots of opportunity to ask questions and discuss your own use of the software with fellow Vectricians.”

In terms of CAD/CAM (computer-aided design and computer-aided manufacturing) software, it benefits you to keep an eye out on the rapid changes in this sector, not only because the cutting, routing, and engraving machinery it helps you interact with is progressing, but also the markets are. From 2D engraved signage to intricate 3D models, the market expectation is becoming increasingly sophisticated, and to cash in on these markets, it is worth investigating into how the back end of the design and production can be tightened up and what new software could help you achieve.

From 2D engraved images to spectacular 3D signs, CAD/CAM software leads you through from initial design, right to the final production, allowing you to offer a much wider range of services to your customers

SA International (SAi) is a global leader in providing software solutions from all areas of design to production for the sign-making industry. They are particularly well-known for their popular EnRoute CNC and CAD/CAM software, which has just launched its sixth version.

Today's CAD/CAM software, such as SAi's EnRoute can enable you to create 3D models using your routing machinery

According to EJ Nodurft, EnRoute product director at SAi, there are a number of factors sign-makers need to consider when looking at new software solutions. He says: “With the increasing demand for quality at a reduced turnaround time and manufacturing cost, sign-makers need to take into account the most cost-effective and efficient software solution.

With the increasing demand for quality at a reduced turnaround time and manufacturing cost, sign-makers need to take into account the most cost-effective and efficient software solution”

“This includes considering the end product that they want to cut and ensure that the software includes the right tools to create this part. Often customers will send sign-makers the files and expect them to be able to import the design file, access drawing and editing tools in preparation of the job.

“Sign-makers should also consider investing in a software solution that offers a good tool path engine that arms them with complete control over the tool paths which can be changed easily when required.

“Lastly, sign-makers should ensure their software program includes good nesting for efficient material usage and that they have control over the output order and a good output engine.”

According to Nodurft, a good CAD/CAM programme should include productivity-enhancing features such as the ability to store and reuse information that would stay the same when using the same type of material, the same tool paths or same design features across multiple jobs or orders. He also says that the software should include a good simulation, as this allows users to verify the tool path and review the finished product before cutting, which is crucial to making sure the output order is correct.

Now, CAD and CAM software can of course exist separately and achieve all of the above, but there are many benefits of owning an integrated solution.

Nodurft explains: “At present, the graphic software packages available on the market are not designed for running CNC routers but are tailored towards output to vinyl cutters and printers. This means that they lack the tools that a programme like EnRoute offers. For example, EnRoute has specialist tools for the preparation of contours for output such as 'clean up contours' to remove excess points and 'convert all contours to lines and arcs', which is what most CNC machines understand.

“Most importantly, CAD/CAM software includes the tool paths necessary to output designs on a router. Most sign industry graphic software is limited to 2D designs and simulated 3D effects, whereas a CAD/CAM software like EnRoute can create actual 3D reliefs and surfaces and 3D engraving, as well as 2D plotter-like cutting.”

Most sign industry graphic software is limited to 2D designs and simulated 3D effects, whereas a CAD/CAM software like EnRoute can create actual 3D reliefs and surfaces and 3D engraving, as well as 2D plotter-like cutting”

That is not all, continues Nodurft, as EnRoute offers sign-makers the ability to offer a vast range of design options, which can often make the difference between a happy customer and an ecstatic one. Of EnRoute, he says: “When it comes to complex design requirements, it boasts a full gamut of 3D surfacing textures, drawing clean up tools, 3D engraving suite and ease of applying complex tool paths. This collectively enables users to bring their signs to life at a fraction of the time and cost, and presents EnRoute as the most comprehensive sign-making CAD solution on the market.”

(Above & below) SA International’s EnRoute 6, the latest version of the software, has the added function of Rapid Texture and Rapid Picture, which allow for amazing textures that are easy and fast to cut

This more or less sums up some of the benefits of this software, which can turn what could be a long, tedious woodworking project into a beautiful sign in a fraction of the turnaround time. One function that aids this is the programme's fast production tools saving capability, which saves frequently used tool paths and easily applies them to new objects. Additionally, the 3D Engrave is accurate to 15 decimals places so it can tool path the most difficult jobs with no tolerance for error.

Essentially, as always, it does come down to the level of quality you want your customers to expect. Nodurft says: “For those who want advanced 3D Engraving and 3D Surfacing abilities or who are looking to extend their applications, having the correct software is integral to ensuring they maintain their competitive edge and moving to a different software solution can prove invaluable.”

The latest version of the software, EnRoute 6, proves that the company always has its eye on what sign-makers need and what the markets are calling for. For example, the newest upgrade features Rapid Texture and Rapid Picture functions, two tools made exclusively for CNC routing, which take basic lines or geometry and create distorted offset lines to produce amazing textures that are easy and fast to cut. Additionally, with the Simulation and Rendering tool, sign-makers can view the finished job before actually cutting, not previously achievable with the current market software. This enables them to perfect their designs and avoid costly iterations further down the production line.

What a relief

One company that has benefited from the use of this CAD/CAM software is Synergy Sign and Graphics, which creates all kinds of signs and graphics, using everything from large-format printers to hand-sculpted concrete. They create 2D, 3D engraved, and full 3D textured signs as well as laser cut and UV printed signs.

Synergy Sign and Graphics has made its name by producing unique and creative signage solutions. The firm has really focused on pushing the limits of its CAD/CAM software and Multicam router

Like many sign-making firms, most of Synergy's designs are drawn in Adobe Illustrator with custom bitmap textures created in Adobe Photoshop. However, when creating engraved or 3D textured signs they then import these files into the CAD/CAM software, using them to create their final designs.

The Synergy team reported that some of the functions in this software, specifically the relief editing functions, have completely changed the way they design their signs and what they can offer customers. Prismatic letters and panel processing are especially easy now and the workflow between their flatbed printer and router works flawlessly. They are now more confidently able to offer 3D carved signs.

One ambitious project they worked on was for Teal Insurance, which involved an intricate engraved design, carried out with the aid of its Multicam router.

However, Jim Dawson, creative director at Synergy, was not content with simply providing the engraved sign itself, but wanted to make the mount part of the overall design as well.

He says: “Gone are the days of boring straight steel mounts. I’m of the opinion that there is a lot of visual pollution in the sign industry. If you can’t make the whole sign interesting, why bother?”

Synergy followed the original design to make the mount look like a tree with the sign hanging from its branch. The metal framework was welded and then covered with wiring to hold the fiberglass-reinforced concrete that would follow. After some priming and glazing, the eye-catching sign was hung, leaving a very satisfied customer.

Start from scratch

The interplay of the CAD/CAM software between the designer and the machinery is extremely important in allowing the customer's vision to come to life. But what if you are new to this and do not want to end up investing in something that may not end up as a huge part of your business?

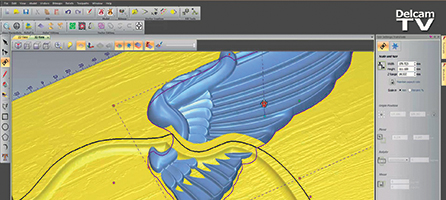

CAD/CAM software developer Delcam offers a range of different levels of products in the ArtCAM family depending on how advanced your firm's capabilities are.

Delcam’s Relief Clipart module being used via ArtCAM Express—the software is part of the software developers scalable range of solutions

ArtCAM Express is an ideal way of venturing into the design of 2D, and manufacture of 2D and 3D models quickly and easily. The entry-level software starts at only £99, and, according to the company, requires little or no machining knowledge to start with, which is helpful if you are new to your routing machinery.

What is more, as your skills and requirements progress, you can purchase extra features to the programme to tailor the software to your business's unique needs. Though the Express package, for example, does not allow for 3D design, but accepts imported 3D designs, there are more than 600 free relief files that can be incorporated into existing designs.

For more advanced signage design and manufacture, you can invest in ArtCAM Insignia, for a mid-level programme, or go the whole hog and install ArtCAM Pro for full woodworking, metal cutting, and engraving capabilities, which offers the added function of creating intricate custom 3D models and moulds from 2D sketches or photographs.

O Factoid: CAD/CAM software is used in many industries besides sign-making, and these days is used to create a vast range of complex products, from engraving and cutting diamonds for jewellers, to creating ice sculptures. O

Delcam also offers a full training programme to its customers, which ensures you make the most out of the new software and relay it to your customers.

In the end it is all about saving time spent in the designing phase and ensuring what is created on screen will be faithfully realised in the final product.

Being able to add complex decoration or logos to signage, without the need to hand finish them post production, could become the added spark for your business. And that is something you definitely do not want to be missing out on.

What is also important to realise is that investing in the right software today, although an up-front cost, will undoubtedly help you reduce your overheads in wasted labour in the long-term.

Your text here...