3D printing to disrupt healthcare

Medical technology continues to advance all the time, with life-saving procedures and medicines that were previously unheard of. Now, Global Data believe that 3D printing could be as disruptive to healthcare as the internet has been to retail.

Wednesday, 20 Jun 2018 14:14 GMT

3D printing could be as disruptive to healthcare as the internet to the retail sector, says Global Data

The company initiated a study for its Disruptor Tech database, and the results revealed that 3D printing could revolutionise the supply chain by limiting the gaps between sourcing, production, and distribution. 3D printing has the ability to create ‘clinical trial ready’ devices without the need for expensive tools, computer-aided manufacturing, and computer numerically controlled manufacturing. As a result of this, price is lowered and waiting times are also reduced.

Bonnie Bain, PhD, global head of pharma at Global Data, explains: “What sets apart 3D printing from other methods is unmatched customisation with high accuracy, its ability to test multiple configurations, and create a patient-specific device more accurately. 3D printers can dramatically reduce the cost of custom-made medical devices, including hearing aids, dental implants, hip replacements, and artificial limbs.”

What sets apart 3D printing from other methods is unmatched customisation with high accuracy, its ability to test multiple configurations, and create a patient-specific device more accurately”

While in the print industry, 3D printing is mostly used to create eye-catching 3D signage and products, the medical sector believes that one day 3D printing could be used to create fully-functional human organs that could be used for transplants. A prototype for a 3D bioprinter to create completely functional human skin has been presented by scientists, and most recently researchers and doctors have printed the most sophisticated artificial cornea using 3D print.

“As the performance and scale of industrial 3D printing platforms continue to evolve,” Bain continues, adding: “3D printing is increasingly finding a way into mainstream manufacturing processes. At present, 3D printing for manufacturing is a discrete, mostly off-site process but, over the course of the next decade, 3D printing will find itself incorporated into existing production lines, with objects printed on demand as the production process proceeds.”

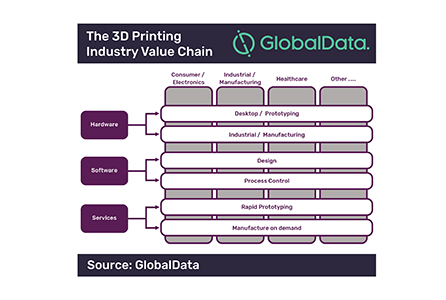

The 3D printing industry value chain

3D printing is also not only limited to the creation of limbs or organs, but can also be used to create drugs, for example, a 3D-printed drug has recently been approved by the US Food and Drug Administration for the treatment of epilepsy.

Bain concludes: “Despite health and safety regulations as main barriers, the prospects of 3D printing remain positive and the market is gaining momentum. While small and medium-sized healthcare companies have already realised the importance of 3D printing, industry leaders have started blazing trails in collaborations.

“3D printing is already used in healthcare but is still largely seen as a novelty. However, over the next 12 to 24 months, 3D printed implants will complete the first stages of clinical trials and the scene will be set for 3D printing to become a standard part of the healthcare portfolio.”

If you have an interesting story or a view on this news, then please e-mail

news@printmonthly.co.uk

Follow Genevieve on: