Mira hybrid: the roll-to-roll set-up can simply be attached to the front of the flatbed of the Agfa printer and can be detached to keep it out of the way for rigid jobs

The wide-format roll-to-roll and flatbed combo has been likened by some to that of a washer-dryer—one machine that does two jobs to a satisfactory standard. But despite some criticisms of the idea that hybrids make more compromises than gains for the user, there is no doubt that in a confined space of a small start-up sign-maker hybrids are a pretty neat solution. And of course there is a saving in price, which is another attraction—especially for those who want flexibility and initially do not have a huge amount of work in their order books. However, the description of hybrid can be a little misleading as some so-called hybrids are flatbed printers, with an add-on roll-to-roll system converting them to hybrids—although manufacturers are quick to point out the advantages of such an arrangement.

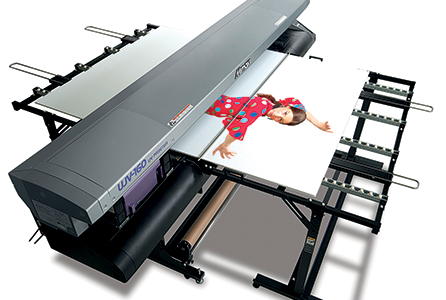

“We have a hybrid in our portfolio, with the Mimaki UJV-160 roll to roll LED flatbed UV printer. It has a precision flatbed and a roll-to-roll hybrid LED UV printer with white and clear ink,” says Stuart Cole, national sales manager, industrial products at Hybrid Services. He adds: “It has a production speed of 8 to 10sq m/h in its highest quality setting and prints onto materials up to 10mm thick. A true hybrid, it’s an 'all in one' machine sporting high end features across the range, comes with a gold warranty, full set of eight inks, take-up unit, folding print tables, and powerful software bundle including the Mimaki Raster Link Pro Postscript RIP.

New hybrid: Mimaki’s UJV160 gives a flexibility for sign-makers at an affordable

cost level

The key advantage of this technology is that it is a perfect fit for those that simply cannot afford more production space, but want to bring flatbed printing in-house and expand their product range to include a colourful and profitable array of new products and services.”

The key advantage of this technology is that it is a perfect fit for those that simply cannot afford more production space”

Cole outlines that another option, if space and budgets allowed it, would be to utilise Hybrid Service’s package deal which would see you able to bundle together a dedicated roll-to-roll system and its flagship flatbed print technology to create a ‘hybrid production system’—the advantage being you can print roll-to-roll and flatbed simultaneously. But if you are on a tight budget, and space really is at a premium, then having a system that enables you to swap between printing to rigid and flexible substrates will certainly give you an edge on competition who need to subcontract out the former.

Best of both worlds

The price is certainly one factor on why hybrids have appeared in recent years. If overheads are high, turnover low, and a firm has only a handful of employees—which is the case for many sign-making outfits—then the small matter of several thousand pounds extra to buy a second machine can put the kibosh on the idea.

A hybrid, however, offers the best of both worlds, with the aforementioned drawbacks.

Another firm with a flatbed printer also capable of working alongside a roll-to-roll is the HP Scitex FB550 from Perfect Colours. Dave Basson of the firm explains: “It replaces the FB500 and FB700 series and comes in two sizes, the 1.6m machine while the FB750 is 2.5m. It comes with three options, one is a white ink upgrade kit which you can fit yourself, another option are additional tables, the third option is a roll-to-roll kit which allows you to put on different substrates.”

Perfect Colours: pictured at this year’s Sign and Digital is this HP Scitex FB550 wide-format printer that can print on almost any rigid and flexible media up to 64mm thick by up to 64” wide

The hybrid aspect of the HP Scitex is created with a quick add-on—giving you two machines for not much more than the price of one. Indeed, an FB550 comes in at under £60,000 and is considered as an entry-level machine aimed at sign-makers seeking to expand their service range. Basson says the thinking behind the design of the product is that production can all be done on a viewing system, so the operator can decide what the final application he wants to print on and then choose from a simplified chart what setting they want.

It is this ability to print onto both rigid substrates and roll-fed material that obviously attracts print service providers, along with a quality finish from trusted brands. Usually when we are talking about UV flatbed printers, a hybrid version is one that is based on a belt driven design, allowing the rigid media to pass below the print carriage during printing, compared to printers where the rigid media remains stationary. But, both have the ability to run flexible media to create a hybrid design.

Versatility in mind

Agfa’s Jeti Mira is a six-colour and white UV-inkjet flatbed inkjet printer that features an option to create a hybrid machine with a dockable roll-to-roll option, allowing the printing of flexible media. The firm describes it as a versatile true flatbed driven by Asanti workflow technology, but crucially Agfa is emphatic that the design of its dockable roll-to-roll unit turns it into a ‘true-hybrid’ as this removable system has been designed from scratch to avoid any compromises in speed, printing accuracy, or media registration.

“This is a printer designed with versatility in mind. As such the Jeti Mira can accommodate a super-efficient roll-to-roll system,” says Steve Collins, inkjet marketing and channel manager at Agfa Graphics. He adds: “It attaches immediately in front of the flatbed table, reducing the distance the media needs to travel and further decreasing the chance of skewing while improving accuracy on the Y-axis. The roll-to-roll system minimises waste, is upgradable, and fits in perfectly with movable gantry. You can also detach it to keep it out of your way when performing rigid jobs.”

Control: Agfa’s Jeti Mira MG2716 has this neat set-up to allow the operator to have finger-tip control of each job

The new generation of inks have also helped to make the hybrid possible, since the technology combination needs to be able to cover all bases. Typically, UV inks need to be able to resist the weather, prevent fading, and stand up to wear and tear where they come into contact with people such as in point-of-purchase applications.

Sarah Lyons of Roland DG explains how its Versa UV LEJ-640FT printer continues to be a hit with a range of sign-makers. She explains that as a hybrid, the LEJ-640 UV inkjet printer is capable of accepting a vast array of substrates, ranging from roll media such as paper and film, to thicker materials as well as packaging and point-of-sale, to wide-format signage, décor, exhibits, and window displays.

Handy unit: Sarah Lyons of Roland holds the control pad for Roland’s Versa UV LEJ-640FT hybrid printer, which she says allows you to take a look at a job while the controls are still in your hand

“The key features include a zoning technology, which means you can have multiple origin points and put multiple print runs on the same bed,” says Lyons, who adds: “This makes production more efficient, as you do not have to setup the machine to deal with different substrates on individual runs. It also has a really useful handy panel at the front, so you hold it in your hand but walk around the machine to check things out and make adjustments to the print running.”

Ending outsourcing

This ability to keep an eye on the work and stay in control with the handy panel on Roland’s machine also illustrates another reason why hybrids are one solution for many companies. Instead of outsourcing work, they can keep printing in-house and improve profits in the long-run with a return on investment. In other words, if there is enough work flowing through the business the hybrid will pay for itself and the uncertainty of farming work out is removed.

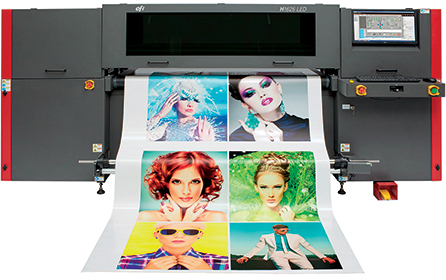

Electronics for Imaging (EFI), a key technology giant in this area, perhaps sums up the benefits of hybrid technology best with this statement: “Hybrid printers offer the ultimate in flexibility, because they are capable of printing roll-to-roll, flexible sheets and rigid substrates in a single footprint. With fast changeover from flexible to rigid materials, hybrid printers offer cost-effective production, and are perfect if you want to provide a wide variety of applications to your customers.”

The EFI H1625 hybrid printer utilises LED UV curing technology and has earned itself as one of the best solutions on the market if your space and investment capacity is at a premium

Indeed, a report written for ITEnquirer specifically on EFI’s best-selling hybrid, the H1625, outlines just why it has been so successful in this area: “With most entry-level wide or superwide format inkjet printers you get a stripped down version of a larger sibling. That’s what is meant with “entry level”, but I for one was surprised to find the EFI H1625 not being stripped down at all. Except for its size, this wide format LED inkjet printer comes equipped with features that you’d only expect to find in larger models,” writes Erik Vlietinck, who adds: “Due to its price and capabilities, I can see the H1625 appealing to small and medium-size print shops. Shops focused on production volumes will love the high speed of this printer and its ability to run uninterrupted—continuously.”

O Factoid: The word hybrid originated in the early seventeenth century and was first used regularly in the nineteenth century to describe the offspring of two plants or animals of different species (in Latin the word meant the “offspring of a tame sow and wild boar”. O

Vlietinck, a technology reviewer known for not pulling his punches but giving praise where it is due, adds: “The H1625 being an LED printer will give these shops an extra appeal with an eco-minded customer base. Finally, service bureaus will love the ability to use the EFI H1625 in combination with EFI products such as DirectSmile that enable them to deliver a combination of printed and digital marketing materials. EFI’s idea of the H1625 LED seems to be to offer printers and service providers who were previously using medium format printers, a chance to ramp up their productivity and market attraction. They can achieve this by delivering their (potential) customers a larger choice of media, with an ecologically justified technology and at the same quality as what they were used to before.”

Clearly a wide-format hybrid device does not suit every business, and choosing whether it is right for you is more a question of deciding how much work a hybrid will be able to cope with. If the workflow is huge, and a business is taking on more and more work that is currently going out of the door to a sub-contractor, then a two-machine solution seems the best fit. But for those smaller firms that are happy with the amount of work coming in with no immediate prospect of a big bump in orders, then being able to suddenly double up a single piece of floor space to become a flatbed printing production area will no doubt open up new product and service areas for your business, improve your creative control, and help you to retain more profit margin per job in the long-term.

Your text here...