HP innovates in healthcare with 3D print

HP is continuing to further innovation in the world of 3D printing with the announcement of two new partnerships related to healthcare provision.

Thursday, 23 May 2019 10:47 GMT

A ‘SmileLab’ engineer produces 3D printed mouth moulds

The first of the two collaborations sees HP join forces with SmileDirectClub, a private orthodontics firm based in Nashville, Tennessee that aims to give customers a straighter smile.

The teledentistry company will become the largest producer of Multi Jet Fusion 3D printed parts in the US by taking on 49 of HP’s systems.

SmileDirectClub will run the 3D printing systems 24 hours a day, 7 days a week, producing more than 50,000 unique mouth moulds a day.

“SmileDirectClub is digitally transforming the traditional orthodontics industry, making it more personal, affordable, and convenient for millions of consumers to achieve a smile they’ll love,” says Alex Fenkell, co-founder of SmileDirectClub.

“HP’s breakthrough 3D printing and data intelligence platform makes this level of disruption possible for us, pushing productivity, quality, and manufacturing predictability to unprecedented levels, all with economics that allow us to pass on savings to the consumers seeking treatment using our teledentistry platform.”

As part of the partnership, the two firms have announced a new recycling programme to further sustainable production of 3D printed parts. Excess material and processed plastic mouth molds will be recycled by HP and turned into pellets for traditional injection moulding.

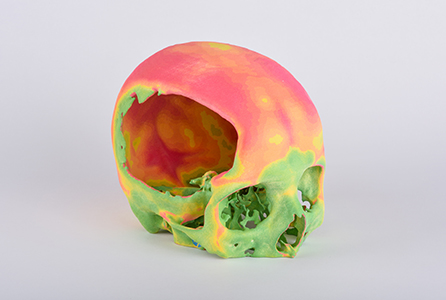

A model skull created using Materialise software and HP Jet Fusion printers

With a focus on driving a sustainable industrial revolution, HP highlights that 3D printing is helping to reduce the amount of materials used, shortening and simplifying supply chains and better matching of supply and demand. The lighter nature of 3D printed parts can also reduce the weight of vehicles and aircraft to improve fuel efficiency.

Currently only available in the US, Canada and Puerto Rico, the services from SmileDirectClub are set to reach the UK and Australia this summer.

The second collaboration involves Belgium software company Materialise, which was the first in the world to receive FDA clearance for its software intended for 3D printing anatomical models for diagnostic use in healthcare.

Materialise has certified HP’s Jet Fusion 3D printing solutions for use with a new version of the Materialise Build Processor, which will be available in the second half of this year.

Free access to Materialise’s Magics Essentials software, which allows users to apply textures or colours and import a range of file formats, will be included for customers of the Jet Fusion 300/500 series for a period of six months.

“Recent advances in technology have created new excitement and growing awareness for 3D printing as a relevant complementary manufacturing technology that will help to transform the factory floor,” says Fried Vancraen, founder and CEO of Materialise.

... manufacturers recognise the economic advantages and are preparing for full-scale 3D printing production runs”

“Triggered by potential design optimisations and the ability to scale and achieve mass-customisation, manufacturers recognise the economic advantages and are preparing for full-scale 3D printing production runs.

“Together, Materialise and HP are innovating to eliminate limitations surrounding 3D printing and creating a more open market model that offers manufacturers more choice, more control and lower cost, ultimately leading to increased adoption.”

The joint effort of the two companies aims to support the creation of point-of-care 3D printing facilities in hospitals, in a bid to advance 3D printing in healthcare.

The certification of the Jet Fusion solutions will allow medical professionals to print robust, full-colour anatomical models for diagnostic and surgical planning processes that will help to deliver more patient-specific care.

Lee Dockstader, director of vertical market development for HP 3D printing and digital manufacturing, comments: “Materialise and HP are working to address potential challenges for healthcare providers by ensuring their 3D operations are fully compatible and able to meet quality standards for developing and printing patient-specific 3D anatomical models.

“Leading hospitals are adopting integrated 3D printing services as part of their medical practices as they recognise the added value it brings to personalised patient care. This joint effort supports the creation of point-of-care 3D printing facilities in hospitals, a critical step forward for advancing 3D printing in healthcare.”

If you have a news story, email summer@linkpublishing.co.uk or follow us on Twitter and LinkedIn to join the conversation.