Abbreviated to PMMA, the material is best known by its trade names of Perspex and PVC amongst others. Developed in the 1930s, Perspex was put to use in the war in place of glass in submarines and airplanes but following the outbreak of peace its potential was seized upon by the fledgling Bristol company Kings Plastics.

The grandson of Jack Underhill (one of the four founders) and now the company’s managing director, Mark Underhill, explains: “Kings initially started manufacturing items from Perspex acrylic sheet and PVC making household goods. Due to the shortage of china cups and saucers, Kings were press moulding these items as well as acrylic trays.”

Now as a company we offer a huge range of services in-house from fabrication to illuminated signs, with edge lighting being our speciality”

From there the firm began to manufacture moulded lettering using the new ICI range of plastics in a variety of colours.

Underhill continues: “We started producing moulded lettering from the limited typestyles available at the time such as standard Roman, Gill Sans block style and Egyptian style. These were then cut and shaped on pedestal routing machines. Flat cut lettering was produced from the newly introduced Letraset and projected onto a screen and trace copied to be then cut by hand.”

“Progressing onwards we then moved to the new Pantagraph machines which were able to cut and scale letters to size using pattern templates you followed with a pin by hand which cut the material adjacent with a router type cutter. This was the norm up until the new CNC computerised router came on the scene in the 1980s.”

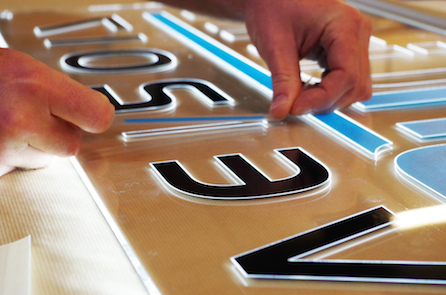

Bending the plastic: creating built up letters requires huge skill and a deft touch

In 1969, Jack Underhill was joined by his son Bryan, who was followed by his son Mark in 1978. The firm now has a workforce of 15 with ten in the factory and five in sales and support.

The firm took delivery of a Gerber Graphix 48 router introduced by Spandex and has continued using the equipment whilst updating its CNC routing capabilities. As the firm grew, so did the workforce, with as many as 40 on the payroll at their factory in Houlston Street in Bristol. Throughout the early 1960s and 1970s, business did well but with recessions and changing technology the company have since moved to a new site in Old Market and paired down to ensure they survive in today’s challenging economic times.

Kings have strived to offer quality products and service for all its customers new and old and with the now ever popular social media sites and internet, due to our new recently updated website and our mobile friendly online shop available”

Apart from Mark, the key figures include Sandra Underhill as finance director, Jenna Underhill (Hart), Mark Graham, and Will Stapleton in sales, and Douglas Mant as production supervisor.

As to the company’s future, Underhill says: “Kings have strived to offer quality products and service for all its customers new and old and with the now ever popular social media sites and internet, due to our new recently updated website and our mobile friendly online shop available. Things can only get better.”

“Now as a company we offer a huge range of services in-house from fabrication to illuminated signs, with edge lighting being our speciality. We stock our own aluminium extrusions for lightboxes, and edge-lit tracks. We also stock LEDS and are pushing our direct LED sales, which we sell direct from our online shop.”

Cutting: the Perspex is cut out using a high precision machine

From those early days in the shadow of the Second World War, the firm has shown how a company can keep manufacturing alive across the generations finding new markets and applications for their work. They certainly have come a long way from the cup and saucer days of the 1940s.