The wide-format fast lane

Brendan Perring charts the relationship that has developed between two technology experts that are at the top of their game, and finds out what opportunities lie in vehicle graphics

Thursday, 29 Oct 2015 14:00 GMT

The fastest motorsport class in the world, the minimalist beauty shared between F1 racing and wide-format inkjet technology are clear to see

The idea that you can only achieve true beauty in technology design when it is a perfect expression of function is a concept that was first embraced by minimalist theorists. This means that, for example, an exhaust system on a Lotus Formula 1 car (see right) is weirdly beautiful because there is absolutely nothing unnecessary about its design—every curve, rivet, and weld is only there to carry out the function of taking exhaust gases from an engine to the rear of the car. This approach is at the heart of every part on an F1 racing car, absolutely nothing is surplus to requirements as competing teams try to shave every last possible 1,000th of a second from their lap times.

The same is true of the wide-format inkjet printers manufactured by those such as Roland DG. They are incredibly simple to look at, indeed the biggest embellishment is the routed metal logo sitting humbly on its front. Width is kept to an absolute minimum around the print head carriage to help reduce overall footprint, inks are held in square plastic boxes that neatly slot into place to achieve maximum ink yields and change-over efficiency, and rock-solid chassis engineering ensures virtually zero movement during printing. This approach is similarly to keep purchase costs for the customer at an absolute low while ensuring maximum competiveness—all without compromising a single dpi of print resolution or square meter per hour of speed. Indeed, the minimalist design of wide-format inkjet machines means there is less to go wrong, and higher speeds and quality can thus be achieved.

(Above & below) Lotus F1 Team utilises a Roland SolJet Pro4 XR-640 and its full EcoSol Max 2 ink set to produce the graphics for both the livery on its race beasts and its promotional graphics

So, it is very interesting to have been allowed an insight into a

partnership that has gone from strength-to-strength between Roland DG

and Lotus F1 Team. The common denominator between the two organisations

is a dedication to excellence and product performance, be that a SolJet

Pro4 XR-640 that runs at 50sq m/h or a Lotus F1 Team E23 Hybrid that can

hit 202mph (325kmh). At the heart of this co-operation is Lotus F1

Team’s visual branding manager Joe McNamara, who has had an illustrious

career both running his own sign-making businesses and working for other

Formula 1 teams to look after their graphics design, printing, and

application needs.

Coming from a family of sign-makers, and with a very deep knowledge of the market, he is emphatic about the commercial

opportunities around vehicle graphics: “There is great scope for the expansion of the vehicle wrapping market. In motorsport it’s currently gaining popularity and we are not the only team to be so heavily involved with it.

(Above & below) Designing, printing, and applying the decals to the Lotus F1 Team cars requires forensic levels of attention to detail

“At Lotus F1 Team we looked at bringing a graphics department in-house

about nine months ago and we looked at the printers that were out there

in the market place. I have personally had a long relationship with

Roland, using their equipment and I know how reliable it is. So when we

contacted them about becoming a possible technical partner they were

very interested in coming and speaking to us.”

The meeting was fruitful and the result is that the duo have created a fully-equipped vehicle branding studio in the heart of Lotus F1 Team’s Enstone base. It was this and the rest of the Enstone-based facility that my two trusty colleagues Sascha May, our media producer, and Karis Copp, our online editor, and I went to film and tour.

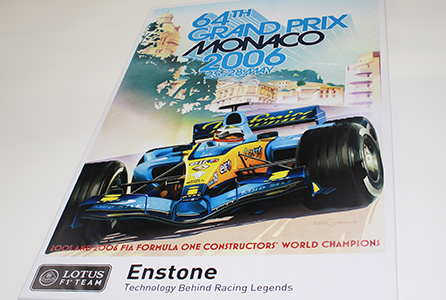

(Above & below) A mix of nostalgic imagery and modern atmospheric branding, all the graphics at Lotus F1 Team headquarters are produced on Roland DG equipment

McNamara continues: “The printer we selected was the SolJet Pro 4 XR-640 and we use for everything from the labels that go on the steering wheels right up to what has just come off the printer, which is a large-format print that will be going in our reception.

“In regard to the synergies between Roland and a Formula 1 team, there are a lot of parallels in that we need technology that is reliable and produces perfect results first time, every time at high speed with top levels of quality.”

Roland is the cutting edge of the industry in wide-format print. In the same way Formula 1 is the cutting edge of motor industry”

A statement from Roland DG UK’s managing director, Brett Newman, serves to further elucidate the motivation behind the partnership: “Roland is the cutting edge of the industry in wide-format print. In the same way Formula 1 is the cutting edge of motor industry. Bringing the two elements together makes perfect sense. I think it is a testament to the technology and to the variety and breadth of application that wide-format technology can be used for. Gone are the days of people using it for just making posters, it’s used across all sectors, all industries, and all applications. Lotus using this equipment is a perfect example of just how wide the market is opening up.”

Walking around Lotus F1 Team on our tour, I was immensely happy to experience what goes on behind the scenes of a sport I am passionate about. More than that though, I was simply staggered by the levels of hard work and technological excellence on display at Lotus F1 Team. And being able to see how its best minds are engaging with an industry I work in just made the experience all the sweeter.

Sign7 News filmed a special video report from Lotus F1 Team headquarters

Sascha May, Link Digital Media’s media producer; Karis Copp, SignLink

online editor; Brendan Perring, SignLink editor; and Joe McNamara, Lotus

F1 Team visual branding manager

Your text here...