Thinking ink

Thinking ink

In the print world, technology is moving all the time, and as press technology changes, so the consumables that run through the machines—namely substrate and ink—must change with them. As new technologies, from LED UV to direct-to-garment presses, crop up, new inks must be developed. The difficulty comes when markets and customers demand new technology but at the same, if not higher, quality than before in order to stay competitive in new fields.

Fortunately, press and ink manufacturers alike have their fingers on the beating pulse of the industry and are developing new ink technologies at a rate of knots to keep up with these demands. One of these companies is Mimaki, which develops inks along-side its presses, to make sure its inks are serving printers and its customers across the board.

UK Mimaki supplier Hybrid Services is at the front of the line in gathering what printers are demanding from their inks and what the market trends are driving towards, as John de la Roche, national sales manager for sign and graphics, divulges.

He says: “Printers are continuously being pushed for faster turnaround, so quick drying inks, such as Mimaki’s SUV, help shorten lead times. Simply put, printers that produce output faster can get through work quicker and satisfy customer demands with greater ease.

Simply put, printers that produce output faster can get through work quicker and satisfy customer demands with greater ease”

“The breadth of ink technologies currently on the market ensures print providers have a wider choice on hand with which they can deliver an even more impressive product to their customers.”

In terms of SUV inks, de la Roche has seen an industry movement towards the technology, for more than one reason. He continues: “Over the last year there has been a very positive uptake of SUV technology due to the multiple benefits it offers printers, such as a high gloss finish that is attractive to a number of sectors. SUV ink dries instantly allowing finishing and or packing to take place directly after printing and it produces a very robust print, useable without laminate in a lot of situations, saving on processing time and cost.

“We’ve also seen the new SS21 colours released; orange to extend the colour gamut and light black to further improve detailed printing. On the latest solvent printers from Mimaki, the SS21 inks perform at impressive speeds, drying quickly and offering a huge gamut, great flexibility and tremendous wear resistance.”

De la Roche says Hybrid’s inks service both wide-format digital and litho customers, meaning printers are able to offer a large range of output, whilst knowing the ink quality will remain constant across jobs and presses: “Litho and digital printers installing Mimaki wide-format solutions can ensure the high quality of output they’re used to with their traditional presses in their digital output, whilst adding the capability to print short runs, one-offs, decals, banners, canvas prints, and plenty more.

“Servicing existing customers with a larger range of products keeps their customers close and being able to positively respond to product requests can stop them looking elsewhere. Having a wide-format printer that can produce a broad selection of work should deliver a wider variety of products.”

Over the years of LED UV wide-format development, there have been some debates as to whether the ink and press technology work together. Rum-ours of ‘tacky’ ink following print work have been heard industry-wide, potentially damaging the reputation of this low-energy, low emission press technology. However, Stuart Cole, national sales manager for industrial products, assures printers that this is not the case, as Mimaki's ink technologies have been developed alongside its machines to ensure highest quality output with all the added benefits of LED UV.

Cole says: “Mimaki’s LED UV printers–from the A3 UJF Series right up to the 10´ x 5´ JFX500-2131—feature cutting edge LED UV curing inks which result in significantly reduced power consumption and therefore reduced CO2 emissions, making it both cost saving and better environmentally.

Mimaki’s LED UV printers–from the A3 UJF Series right up to the 10’ x 5’ JFX500-2131—feature cutting edge LED UV curing inks

“The inks allow printers to work with more substrates, including heat sensitive media as the lamps are cool, working faster and more creatively. With bright, opaque white ink available it’s possible to print to coloured and clear substrates yet still achieve punchy vibrant colours, and with clear ink, varnish effects are possible too.

“The advent of this type of ink from Mimaki means the choice for the print professional has never been greater, which naturally results in print providers being able to offer more options to their customers.”

Driving technology

One of the leading manufacturers in Korea, InkTec, has been supplying various kinds of inkjet printing ink products to around eighty countries over the last 22 years. InkTec says what sets it apart is that, unlike other ink suppliers, which outsource ink products from outside the company, it designs and manufactures various inks and related products alongside its own technology.

The company says that its main mission currently is to make sure that inks can keep up with what printers, and their customers, are demanding. InkTec says that, as printers expect more and more in terms of speed, and their customers increasingly demand the ability to print on an ever-widening variety of media, it is becoming imperative to ensure inks dry effectively and efficiently.

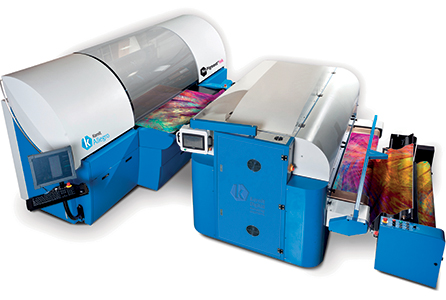

Mimaki has noticed a rise in popularity in its SUV quick drying inks due to a need for faster production turnaround

The reality is that it is all very well and good to have a highly productive printer in terms of speed, but ultimately a wide-format printer is also massively reliant on how quickly the printed inks dry.

As Joey Kim, managing director at InkTec Europe says: “This is why, at InkTec, we are constantly focusing on researching and developing methods and approaches using the latest technology to ensure we have the very best UV lamps or heaters on our Jetrix printers. Alongside this, our in-house experts in our technical institute are constantly innovating ink structures and formats to create advanced UV curable inks.”

These evolutions mean that recently, to coincide with the launch of the Jetrix RX3200, InkTec created a range of new UV curable inks for its latest roll-to-roll printers, specifically designed to ensure the ink flowed well, even at high speeds.

InkTec is also known for its eco-solvent inks, for use in outdoor and indoor printing, due to their high UV resistance and high quality on various media. EcoNova and, newest ink, EcoNova Pine, are designed to be compatible with OEM inks in terms of colour and physical properties but also offer printers the ability to up their environmental credits, as EU and global emissions regulations become more of a concern. InkTec says EcoNova Pine is an environmentally-friendly ink, with no VOCs and odour, making it ideal for indoor use.

In addition, to target another lucrative market that many digital printers are moving into, InkTec has also created a series of dye-sublimation inks developed specifically to the unique requirements of particular print heads to ensure printing speeds and drying times can be maximised.

SubliNova—a contraction of ‘sublimation’ and ‘innovation’—inks can be used not only with direct-to-garment printing, but also using traditional heat transfer paper. InkTec says that the inks were made with small particle sizes of dispersive dyes under 100nm (0.1µm) to ensure smooth ink flow without head clogging.

SubliNova Smart inks also offer superior printing quality in various printing environments (from -20 °C to 40 °C) and use high-class dyes to keep their colour shades in harsh conditions. With printer compatibility ranging from Epson Stylus machines, to Mimaki, Mutoh, and Roland printers, the inks are fast drying, offering enhanced productivity, and strong out-door durability. InkTec also promises that the inks are environmentally-friendly, free from formaldehyde, VOCs, Alkylphenol and comply with with RoHS (Restriction of the Use of Certain Hazardous Substances).

Directly speaking

On the subject of dye-sublimation, Kornit Digital is a rising star in the market. With an emphasis on enabling textile printers to be able to produce shorter, unique runs of fabric and clothing, the company has invested as much effort in its new DTG (direct-to-garment) print systems as it has in its inks.

At this year’s FESPA, Kornit Digital announced that it had produced a new and improved series of inks to encourage this burgeoning market. Guy Zimmerman, vice president of marketing and business development, says that the new series of inks, Neo-PigmentTM Pure, which were demonstrated live on the company’s Avalanche XR system at FESPA, would support the entire line of their DTG systems. Following the final phase of beta testing, the company promises it will be fully available come October 2015.

O Factoid: When Gutenberg created the printing press, a new kind of ink had to be manufactured. This dye was indelible, oil-based, and made from the soot of lamps mixed with varnish and egg white. O

Zimmerman comments: “We are very proud of the new chemistry in our new inks. We have seen a significant improvement in gamut, much more accurate colour which enables better Pantone colour matching, better details, and better gradients. The white base, which was very good before, is also much better now. In fact, we believe it is the leading white base in the DTG industry on parameters.”

NeoPigment Pure ink is made up of CMYK plus red, green, and white, with an increased gamut of over 15 percent, a deeper black and a greater opacity and brightness of white. Kornit Digital also claims the inks are 100 percent biodegradable and sustainable, with a reduced odour.

Kornit Digital's direct-to-garment roll-to-roll system, Allegro, will utilise its new ink range, NeoPigment Pure, which boasts a host of new improvements for higher quality output

Zimmerman also emphasises that, aside from the colour, the feel of the inks have been greatly improved. He says: “The touch, which was previously our Achilles’ heel has been improved and now provides what we believe is an ideal hand feel. We also have better performance on synthetic fabrics than before, and the quality is enhanced. So, we are very proud to arrive with a new improved technology from our core product.”

As a final note, Zimmerman makes the case that overall, high quality is what textile print customers are demanding especially in such competitive, and lucrative markets, as fashion.

He concludes: “Yes we have fantastic systems, yes we have hundreds, almost thousands, of customers around the world. We can cater to huge production set-ups but now the market and our customers are demanding higher quality. As we are entering the fashion market, we are now introducing this new level of print quality and we are getting to a level of detail and print quality that we are very proud of.”

With so many ink technologies available for so many markets, and a clear focus on improving quality at every turn, it is clear that industry manufacturers have printers’ concerns at the forefront of their minds when it comes to gamut, quality, and feel. In which case, printers would be wise to investigate which new inks could be working wonders for them and potentially bring new custom and happier customers.

Your text here...