Aim for accuracy

It is no secret that print is now re-emerging as a valuable tool for marketers and brands, with wide-format applications such as billboards, posters, banners and flags often forming market of modern campaigns.

However, when it comes to printed work in this sort of environment, colour is of paramount importance to campaign managers. Some colours are associated with certain brands – think the Coca-Cola red or the yellow arches of McDonald’s – so matching these colours is key when printing materials.

Colour management software offers both wide-format printers and sign-makers an effective way of ensuring that the printed work they are producing is in line with the exact requirements of the customer. Here, we look at some of the latest options available to the market.

Profitable move

GMG Color specialises in the provision of colour management solutions to the industry. Marketing manager Amy Young summarises why such a product is so important for wide-format printers and sign-makers involved in print, saying the software helps the user create more profit in the long term.

“A quality colour management solution sits centrally within the business and links up all departments to ensure a simple but powerful process, allowing you to manage output to any print process or substrate prior to production,” Young says.

“Most companies will operate with a simple RIP or workflow but the question that should always be asked is: ‘what process could we add or remove to improve efficiency and quality, remove cost from the current process and enable more profit from the items produced?’

“Customers who demand consistent colour results for multimedia campaigns will not be satisfied with colour management systems that can’t maintain brand colours across different devices and substrates. Therefore, a company that hasn’t invested properly in colour management could hit issues with rejected work and loss of a client.”

O Factoid: Contrary to popular belief, Coca-Cola has always had a red label. Rumours had suggested the company changed from green to red after an advert showed Santa Claus drinking the bottle in his red suit. However, Coca-Cola maintains that the red colour dates back to its early days, around 130 years ago. O

In terms of what is available from GMG, Young cites GMG InkOptimizer, which works through under colour removal to reduce the amount of coloured ink and replace it with less expensive black ink, while improving colour quality. Young says GMG InkOptimizer also allows the presses to run at full speed, reduces wear and tear on printheads, and prevents mottling and streaking.

GMG Color says colour management systems must be able to maintain brand colours

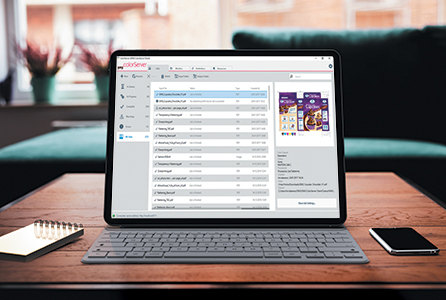

GMG also offers a more precise solution when working with key colours utilising its OpenColor technology. Previously, custom swatch charts would be output to visualise the range of colours to match against a client’s logo or brand colour. Young says this is no longer the case with GMG, as it can build colour books that work directly inside GMG ColorServer, or even share the best match CMYK mix for artwork creation.

“ProofControl is also heavily used with our customer base,” Young adds. “By adding a small mini wedge to each print, we can then give operators the ability to measure these with a spectro device and score the print so you know if the print is a pass or fail.”

One of the new features in ColorServer 5.0.6 is the ability to adjust a digital print machine to a custom input colour space, through GMG SmartProfiler. This sits alongside existing ColorServer benefits, such as load balancing up to eight jobs in parallel and direct integration into third party workflow systems.

One of the new features in GMG ColorServer 5.0.6 is the ability to adjust a digital printing machine to a custom input colour space

Young adds: “GMG ColorServer sits within many of the UK printers either as a standalone server or with the powerful connections of API or XML.”

Retain clients

Also active here is ColorLogic, a developer of colour management technology and software solutions. Product manager Dietmar Fuchs sums up the role of these systems nicely, saying they allow users to print better quality and produce less waste.

Fuchs expands: “Instead of adjusting colour during the ramp up phase in the printing process, colour management allows you to create a fingerprint of your output device and adjust the output before printing. If this is achieved by using a colour server, such as ColorLogic ZePrA, this process can be automated and helps companies to be more profitable.

“However, if you fail to invest properly in this kit, your work becomes much less efficient and more cost intensive. You risk losing clients because the work you produce is not good enough in terms of quality, while you will also face higher costs.”

If you fail to invest properly in this kit, your work becomes much less efficient and more cost intensive”

For those seeking to invest in this type of software, Fuchs points in the direction of ColorLogic solutions such as the ColorLogic ZePrA, a smart colour server that automates colour management in print production for pixel and PDF data. The latest version of this software - ZePrA 7 – supports PDF 2.0, PSD Layers during colour conversion and ISO 19593-1:2018, and also has an extended spot colour module.

The latest version of ColorLogic ZePrA supports PDF 2.0, PSD Layers during colour conversion and ISO 19593-1:2018

Also available from ColorLogic is the ColorAnt, which allows uses to both analyse and optimise measurement data in the print production process. ColorAnt 5 has a new colour editor, custom measure charts with up to nine channels and also improved viewing and comparing options.

In addition, ColorLogic CoPrA is a colour profiling application that generates output and DeviceLink profiles. CoPrA 5 features DeviceLink linearisation, as well as gamut visualisation, black point options and grey balance modifications.

Speed and accuracy

Also weighing in on the debate is Xerox and Kevin O’Donnell, head of marketing, graphic communications and production systems at the digital print company. O’Donnell says colour management is one of the primary tools for any printer, as it provides accuracy and consistency against brand, design intent and print delivery.

O’Donnell expands: “Printers running across multiple devices need to ensure consistency and in today’s ever demanding world it has to be fast, automated and easy to use. Today’s market demands that software adds automation to the workflow, providing consistency, speed and accuracy to any repetitive task, whilst releasing time back to the print business.”

Kevin O’Donnell, head of marketing, graphic communications and production systems at Xerox, says software can help add consistency, speed and accuracy to any repetitive task in the print production process

Xerox offers a portfolio of colour management solutions that can sit either on the digital front end, prepress or in the cloud, as well as wider workflow tools. With regards as to how such products will fit in with an existing workflow, O’Donnell says Xerox is committed to helping the wider market, be it those using Xerox print kit or otherwise.

O’Donnell says: “At Xerox, we pride ourselves on integrating automation and accuracy with broader workflows, whether this is across marketing automation, ecommerce, prepress and even post-press. This integration offers businesses a joint approach, working with both Xerox and our partner products.”

He adds: “Colour management is one of the primary tools for any printer, it provides accuracy and consistency against brand, design intent and print delivery.”

O’Donnell’s closing comments appropriately conclude this feature, setting out just how important it is for modern PSPs and sign-makers to have some form of colour management software in place to assist them with the production of printed materials.

Software providers say investment in quality colour management products can help print service providers and sign-makers save on costs, time and waste

Customers are demanding much more from their print providers in the modern market and in order to retain valuable and profitable contracts, as well as keep ahead of the competition, you need to ensure that the work you produce is of the highest quality.

Of course, investing in the latest printing presses and finishing machinery plays a huge role in both the look and feel of a final product, but by paying attention to the type of software you use, this can help you save on costs, time and waste by cutting out mistakes earlier in in the printing process.

Your text here...