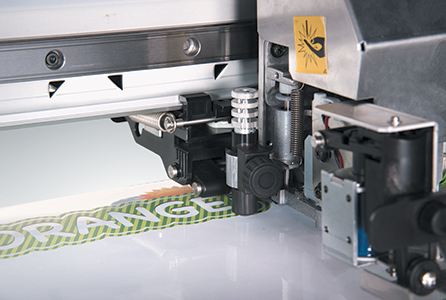

Cut2.jpg)

Roland DG says that machines in its Camm-1 GR range can be used to produce an array of applications, such as vehicle graphics

Walking around exhibition halls at this time of year, it is hard not to be drawn to the mass amount of new, impressive technology on show from some of the global industry’s biggest hitters. Shiny wide-format printers fresh from the factory floor are often a favourite with punters, as are their larger-format cousins.

However, while digital vinyl cutters may not be the star of the show and unlikely to have crowds gathered around them, this technology remains a core bedrock of profitable product manufacture for thousands of sign-makers.

With this in mind, we look at how users of this kit can maximise their profits in the long-term by understanding what the latest upgrades and updates to this technology have on offer, and how it can benefit their own business.

Reliable technology

One of the leading brands in this market is Roland DG, which has a number of solutions on offer, including the Camm-1 GR range. Mark Elvidge, senior product manager, says the company has made a series of upgrades in recent years in order to keep up with changing demand.

Roland DG changed the design of the cutter to an L shape on its Camm-1 GR series

“We’ve made a huge number of updates to digital vinyl cutting technology,” he says, adding: “For example, to increase performance and accuracy, our systems now use digital servo rather than stepper motors, while altering the design of the cutter to an L shape on the Camm-1 GR series maximises stability and therefore accuracy at high speeds.

“Roland users have a larger variety of compatible materials thanks to an increase in cutting force to 600g, a new overcut function that can emulate tangential cutters on a lower cost platform—allowing media such as certain industrial reflective vinyl to be cut—and new electronic pinch wheels to allow custom pressure on media to avoid damage.”

Other enhancements include changing the cutting blades on Roland systems so that they can now retract fully for long vinyl movements and partially for short movements. Roland Camm-1 GR cutters also have both die-cutting and kiss-cutting blade holder positions, meaning users can cut and finish on a single machine.

O Factoid: Roland DG’s range of large-format vinyl cutters, the Camm-1 GR-420, GR-540, and GR-640, have a list price ranging from £4,159 to £4,899 depending on

cutting width. O

Elsewhere, optical sensors allow integration with RIP software and standalone printers. Elvidge says multiple connectivity options including ethernet and USB, included design and production software, and plugins allowing use from popular design package applications offer “better synergy”.

Elvidge adds: “On the surface, cutting hasn’t changed much in 30 years, but actually there have been many developments. For example, look at blade holder and blade development; there are now specific blades for challenging applications that offer better blade life.

“Your cutter should be complementary to your other equipment and integrate into your workflow. A well selected cutter will be reliable and serve you for many years with minimal maintenance; selecting a device that meets your needs now and in the future is key to what will you be producing next year, and in the next five years.”

Your cutter should be complementary to your other equipment and integrate into your workflow”

Elvidge continues: “Cutting is a well refined solution which means major innovations are difficult, but smaller refinements are made all the time to meet changing market demands. The ability to cut more types of media and perform different applications has been achieved by increasing force and adding new cutting methods, which, for instance, allow more complex yet stable graphics.

“Everyone wants to do more with the equipment they have and that is of course understandable, and at Roland we’re always working to help our users achieve that.”

Pushing development

Also active in this market is Mimaki, which is represented in the UK and Ireland by distributor Hybrid Services. John de la Roche, national sales manager at Hybrid, says investment in new and upgraded kit is critical for companies keen to differentiate themselves and gain an advantage over competitors.

De la Roche says: “Mimaki has a strong, and justified, reputation for innovation and the cutting technology that for a number of years has been incorporated in its integrated printer/cutters has recently been added to its UV printer line-up, with the new UJCV series printer/cutters sporting built in cutting capability.

As Mimaki’s new UCJV printer/cutters are capable of producing cut vinyl, Hybrid Services says this will allow users to expand their services to include new products

“These state-of-the-art machines offer sign-makers and print-service-providers (PSPs) an unrivalled opportunity to diversify their product range using just the one machine with the new UCJV capable of producing cut vinyl, printed and cut stickers, signage, point-of-sale, banners, canvas, and even textile backlit output.”

While the focus for many in the market will be on hardware solutions and what this can do for their business, De la Roche says it is important for companies to look beyond this at software options—something Mimaki is committing to research and development at present.

De la Roche expands: “Mimaki has been at the forefront of digital vinyl cutting technology for many years and recent price reductions have made this cutting edge technology even more affordable, with no compromise to build quality or performance.

“Mimaki is also pushing the development of integrated cutting software and recent advances have been made in the packages that are included with all Mimaki cutters to incorporate bar-coding into registration marks for print and cut applications.”

Affordable technologies

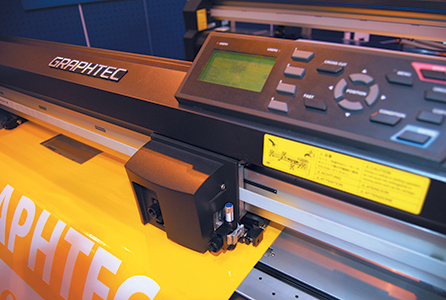

Elsewhere, Graphtec GB has also dedicated significant research and development resources to kit in this sector of the market and has made several advancements in recent years. Director Phil Kneale picks out a selection of examples to demonstrate this commitment.

Graphtec makes excellence in cutting its business

Kneale expands: “The FCX2000 is Graphtec’s latest flatbed cutter for the processing of both rigid and flexible media. It features a twin-head cutting and creasing tool configuration that will enable both of these functions to be carried out simultaneously.

“The CE6000 Plus is a new addition to the popular CE series of cutters that incorporates a number of new and enhanced features to enable even higher levels of productivity. A further addition to the CE series is the new entry-level desktop-mounted CE Lite-50 cutter.

Graphtec GB’s CE6000 series features three models: the CE6000-40, CE6000-60, and CE6000-120

“Incorporating higher productivity features normally associated with the more expensive CE and FC series of cutters, it is available at under £700. As with all Graphtec cutters, the CE Lite-50 incorporates Graphtec’s latest proprietary version seven of the Automatic Registration Mark Sensing (ARMS) system that enables radically enhanced media plotting and cutting accuracy.”

The CE6000 from Graphtec GB boasts a top cutting speed of 600mm/s and a maximum cutting area of 375mm x 50m

Kneale goes on to map out the importance of investing in new kit, saying that with technology moving so fast in this sector, having the latest machinery in place at your worksite will ensure you can make the most out of these new advancements.

Kneale explains: “Most technological advances in recent years have related to improving workflow capabilities, which have resulted in huge savings in manpower requirements. New technology has never been more affordable than today.

New technology has never been more affordable than today”

“A fast return on investment is virtually guaranteed, given the adaptability of digital cutting technology to additional markets such as labelling and packaging and with little or no new capital investment being required.

“Today’s digital cutters and dedicated software have been designed to work hand in hand with the latest printing technologies. For example, Graphtec’s latest Graphtec Pro Studio design and production software will work with all current hardware from the leading manufacturers, while the Graphtec ARMS system for detecting media registration mark locations is now recognised as the industry standard for this particular technology.”

Although digital vinyl cutters may not be the most glamorous of machines in the print and sign-making industries it is clear that they have a key part to play in production at many companies. As is the case with most areas in both of these markets, technology is advancing at an alarming rate and it is the responsibility of the PSP or sign-maker to ensure that their kit is up-to-date.

On the one hand, it is easy to become comfortable with a piece of kit. After all, you may have been using it for a number of years and are not only familiar with it, but also aware of exactly what it can do and how you can use it to its maximum potential. However, looking at the argument from the other side, you can ask yourself, ‘If this older piece of kit can do so much, then what can new machines do for me?’

It is the same when buying a new car or parting company with a mobile phone that has been your trusty companion for the past two years or so. Yes, you are going to miss it and may cost you to upgrade, but more often than not, you are left satisfied with the results. The same can be said with digital vinyl cutters; the initial cost may put you off, but the benefits are valuable and plentiful in the long-run.

Your text here...