Crazy Fly Kiteboarding from Slovakia opted for a Genesis 2200 Laser Flatbed System from Blackman and White to support its production of kiteboarding products

When I took my first, rather tentative, steps into the sign industry back in 2011, as deputy editor of SignLink, it became rather clear that I would have to find my footing quickly and come to terms with the varied terminology that the market throws up—some more exciting than others.

However, when the subject of laser cutters was first mentioned, my mind was immediately drawn to images of James Bond strapped to a table, with a villain standing over him, complete with a white furry cat and evil laugh.

However, it did not take long for me to realise that laser cutters can be put to a lot more use than just torturing 007, with such technology a popular choice for the production of various work in that sector.

While my lack of knowledge at the time may have been forgiven, professionals in the sign industry have no such problem and are all too aware of the advantages that laser cutters can offer to their business. However, when it comes to selecting the right product, this is where the process can become a little tricky, due to the immense selection of solutions available. So, what questions should sign-makers be asking when purchasing this type of kit?

Ahead of the game

One company well placed to offer advice and solutions is Grafityp, which has a range of options on offer. Neil Stevenson, commercial director and UK managing director, says sign-makers looking to invest in laser cutting kit should do so with care, advising that they only purchase machinery that is of high quality to avoid issues later on.

“Buying cheap machinery could mean your pocket becomes a bottomless money pit once things start to fail and that the desired end results on work carried out may not be quite as you expect,” Stevenson says, adding: “This doesn’t mean that what you buy necessarily has to break the bank either to get peace of mind.

“At Grafityp UK, we have a long standing business partnership with GCC, having watched their Laser Pro machines evolve over many years as they constantly endeavour to stay ahead of the game, introducing innovative new features and machines which have the capability of producing stunning engraving as well as cutting results.”

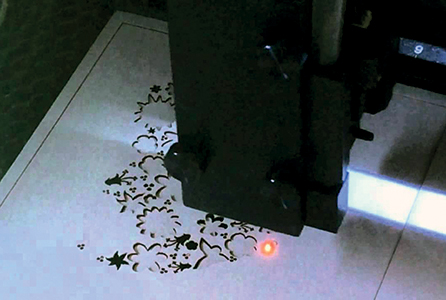

Examples of how sign-makers can use Laser Pro from Grafityp to produce a host of applications, some of which are outside of the more traditional signage work

Laser Pro machines, which Stevenson says are “extremely competitively priced”, are solely manufactured and supplied by GCC, and are compliant with all RoHS regulations, as well as being lead free. Featured in the range is the LaserPro X series, which consist of the X252, X380, and X500III. All three models can cope with cutting anodised metal, acrylic, MDF, leather, textiles, and signage, with each machine featuring a different sized work area.

Meanwhile, the MG380 Hybrid, which also features within the LaserPro range, is equipped with both a metal and a glass laser tube, allowing users to produce engraving and cutting on one work piece, and one machine, on a wide range of materials. In addition, the T500 is capable of cutting at high speed and is equipped with a powerful 200watt laser tube.

Stevenson also highlights the Laser Pro FMC-280, a compact laser system with a powerful fibre laser source: “It will produce spectacular cutting edges and excellent output quality. It is perfect for specialised engineering projects, prototyping, education and customisation work. It will cut stainless steel, aluminium, copper and thin metal mesh, as well as carry out engraving work.

Available from Grafityp, the LaserPro FMC-280 is a compact laser system that features a powerful fibre laser source, and can cut stainless steel, aluminium, copper, and thin metal mesh

“Laser Pro machinery can be an asset across a wide variety of trades whether cutting, engraving or marking as well as in education in such fields as engineering, technical or design.”

Access new business

Also active in this area is Watkiss Automation, whose communications director, Jo Watkiss, says that purchasing the right piece of kit can help your company win new work and access new streams of revenue as a result.

Watkiss explains: “Investing in the right equipment can give access to new markets and customers, improve your productivity and contribute to your bottom line. But to get those results you need to choose a machine that will cost effectively deliver the performance you expect from your capital investment.

Investing in the right equipment can give access to new markets and customers, improve your productivity and contribute to your bottom line”

“‘Going cheap’ in itself is not a problem, but ensuring the appropriate standards of quality, safety and machine longevity is essential. For example, with laser cutters, you should be thinking about the source of the laser beam, the safety of the system, and the overall quality of cutting performance.”

With this in mind, Watkiss draws attention to some of the solutions available from her company. Watkiss Automation serves as the UK distributor for German manufacturer Mohr and, as such, is able to offer customers the Mohr Digicut laser cutter.

O Factoid: Available from Watkiss Automation, the Mohr Digicut has a working area of 860 x 610mm and can cut at resolutions of up to 3,000dpi. O

The Mohr Digicut has a working area of 860 x 610mm, operates from vector-based drawing programs such as Illustration and CorelDraw, and is able to cut at resolutions of up to 3,000dpi.

Available from Watkiss Automation, the Mohr Digicut can cut at resolutions up to 3,000dpi

Expanding on the abilities of the machine, Watkiss says: “This innovative laser technology opens up numerous possibilities for digital and commercial printers. The laser enables the most intricate contours to be not only cut, but also perforated, creased and engraved—all in a single pass and on a wide variety of materials—and of course there is no need for tool changes since this is a laser operation.

(Above & below) The Mohr Digicut can produce applications such as invitations, covers, folders, and packaging. Pictured: the machine being used to create a greeting card

“Applications are financially viable from run lengths from one up to several hundred and can include greeting cards, invitations, covers, folders, packaging, letter heads, name cards, table cards, puzzles, lanterns, bookmarks and coasters.”

Importance of finishing

For those companies focused on the large-format market, Blackman and White is a UK manufacturer fully committed to developing flatbed cutters for the sign and display industry. Alex White, managing director, explains that the firm’s 50-year stay in the market places it in an excellent position to support business that are on the lookout for new, quality solutions.

Alex White, managing director of Blackman and White, says finishing is just as important as print production, and companies should keep this in mind when committing to new investment

White comments: “When it comes to guaranteeing happy customers in sign and digital, your finishing is as important as your print production. Investing in a laser cutting system that’s efficient and reliable will not only deliver a superior end product but also optimise your profit margin through higher speed production and accuracy and reducing the need for subcontracting.

“But don’t presume that any laser cutter you find will be suitable for the range of materials you might want to work with, as that’s one of the compromises you’ll need to make if you’re looking at the cheaper end of the market.”

With this warning, White goes on to highlight some of the challenges that firms may face when investing in machinery: “We’re in a world that doesn’t stand still for long. Customers are always looking for new signage solutions that set them apart from the rest—it makes sense to work with a manufacturer who keeps up with market developments so that as the materials change, the machine capability keeps up with the pace.

“Also, as your business grows so does the time needed for finishing, and using a quality laser cutter will remove some of the labour hours spent welding textile seams to prevent fraying. Another issue to watch out for is the yellowing that can occur with laser cutters which haven’t been correctly configured.”

Moving on to highlight some of the solutions available from Blackman and White, managing director White cites the 100w laser cutter, which is interchangeable with router and knife, thus enabling it to cut more varieties of substrates. The laser cutter option is available on the firm’s Versa-Tech, Genesis, and Master Cut ranges.

White adds: “It is invaluable for textile cutting—a really exciting growth area for signage and just one of the areas in which we’re helping our customers get the best return from their investment.”

Slovakian firm Crazy Fly Kiteboarding is one company to have invested in laser cutting kit from Blackman and White, thus demonstrating the flexibility of the machines. Crazy Fly specialises in producing Kiteboarding products, supplying solutions to more than 100 countries, and purchased a Genesis 2200 Laser Flatbed System in March of last year.

Pavol Bukovcak from the firm says: “We are extremely proud to be the first and only kiteboarding brand producing all of our products in our own factory. This gives us unlimited opportunities for improvements and the implementation of innovative materials and technologies, which in turn give our products a competitive edge resulting in year-to-year growth.

“Involvement of high tech machines such as the Genesis and highly skilled people is vital to get a precisely made kite with the best possible shape and flight characteristics.”

So, while none of the manufacturers or suppliers here mention a certain secret agent in their answers, what is clear is that laser cutters can offer a host of major advantages to those that opt to invest. However, just as James Bond relied on Q to ensure that his gadgets, guns, and cars were in full working order, firms on the lookout for a new laser cutter should also seek out companies established as providers of quality kit.

All of those featured here have made no qualms about the fact that not all laser cutters are up to scratch, and, as with any other area of technology investment in the industry, purchasing quality kit is the best way forward. Although this may mean more cost up front, it will undoubtedly save you time and money in the long run, as well as help establish your business as a trustworthy, reliable setup that will attract customers again and again.

Your text here...