Roland DG says the flexibility of its VersaUV LEF-300 means that users can produce an impressive array of high-value promotional and personalised products

As many in the UK sign industry will know, advances in technology has meant that companies can now go much further than just vinyl and print on what seems an endless array of surfaces—ranging from card and canvas, through to glass and wood.

A number of major manufacturers have already got in on the act, including some associated with wide-format—one of the most vibrant sectors of print—meaning those companies that take on work that requires direct-to-object print are well stocked when it comes to investing in new kit.

However, as with any part of print, selecting the right technology is no easy task, as it is critical you invest in the machine that is right for you and your business. Here, we speak to some of the manufacturers involved in this sector and find out about some of their latest options and how this kit can help sign-makers enhance their direct-to-object output.

Invest in quality

One major name involved in this sector is Roland DG, which stocks a selection of direct-to-object print machines.

Rob Goleniowski, sales support manager at the company, says that while this area of the market does present opportunities for growth, it is important for PSPs to invest in quality kit in order to achieve high quality output.

“A common misconception across the print industry is that the biggest motivation behind a product purchase is cost,” Goleniowski says, adding: “In the current competitive market, it is easy to see why print businesses can become focused on finding ways to drive down production costs in a bid to boost affordability. But recent research by Deloitte has revealed that shoppers of today are actually less motivated by price when it comes to their spending habits.

“In fact, despite consumers buying less products overall, they are willing to spend more per purchase on average, provided there’s a high-quality feel and distinctiveness to the product they’re buying. To reflect this shift in consumer trend, it is essential for businesses to invest in quality equipment that produces superior results every time.”

With this in mind, Goleniowski goes on to outline the solutions available from Roland DG for those companies looking for a quality direct-to-object solution. Such products include the VersaUV LEF-200 desktop printer, which Roland DG says can print directly onto virtually any 3D object up to 100mm in height, and a diverse range of media including acrylic, wood, board, metal, glass, and plastic.

The LEF-200 features an on-board primer ink option that the manufacturer says allows the user to prime objects “quickly and conveniently”, as well as prepare an object for customisation before printing a full-colour graphic to ensure adding graphics to challenging media is a more “accurate and efficient process”.

Sign-makers on the lookout for a larger and faster machine could consider the VersaUV LEF-300, which is also supplied with the primer ink option, as well as other features that are designed to boost production. Users will also benefit from a printing area measuring 770mm wide by 330m long, while the machine can operate up to 60 percent faster than its sister models.

Goleniowski is also keen to draw attention to the consumables on offer from Roland DG, commenting: “By utilising advanced inks, such as Roland DG’s Eco-UV inks, users can also create a unique, luxury embossed effect by layering gloss ink to produce both gloss and matte finish, plus white ink to help graphics pop on transparent substrates.”

Creating new markets

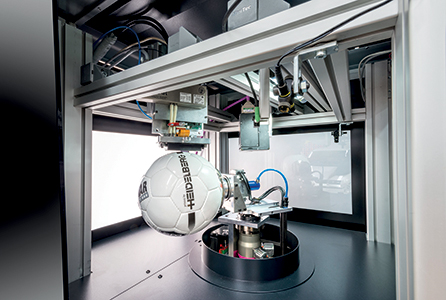

Also firmly in on the direct-to-object act is Heidelberg, whose digital equipment business manager, Chris Matthews, says that despite it still being relatively early in this market, there are opportunities for growth.

Chris Matthews, digital equipment business manager at Heidelberg, says printing onto objects is “ideal” for companies that print for popular brands, with an audience that would appreciate personalised products

Matthews explains: “Printing onto 3D objects can create a new market for commercial and packaging printers, and would be ideal for companies that print for popular brands with an audience that would value personalised products. Football clubs are a typical example where products like footballs, phone cases or drinks bottles need to be personalised or corporate gifts producers.

Printing onto 3D objects can create a new market for commercial and packaging printers”

“The first company to install an Omnifire 250 was My Muesli in Germany, which offers bespoke cereal in a personalised tubes to match. Printers should consider whether they have the market and set up for this type of equipment; if they don’t print onto 3D objects, the product manufacturers or brand outlets will do it themselves.”

German company My Muesli was the first to invest in an Omnifire 250 from Heidelberg

Expanding on Heidelberg’s Omnifire range, Matthews describes such products as ‘4D solutions’, with the fourth dimension being the print applied to the 3D object. The Omnifire 250, the first product to launch in the portfolio, features a four-axis robotics that allows for printing onto objects from 10 to 300mm in diameter. The printing system can apply one to four colours, with the opaque white and protective coatings also available as options.

Last year, Heidelberg further enhanced this range of solutions with the launch of the Omnifire 1000, which handles objects with a width from 50mm and a length of up to 1,400mm. The machine’s six axes robotics enables it to handle a variety of shapes, printing onto every side.

With talk of the manufacturer developing an Omnifire XL in the future for use in large-scale jobs such as automotive or aircraft environments, Matthews says that there is plenty of room for growth in terms of the technology in this area of the market.

Matthews adds: “Heidelberg has opened a dedicated Omnifire showroom in the US and the next to open will be Asia, part of a global roll out. This takes the power of print to all corners of the retail, manufacturing and commercial world and promotes the power of the brand and the individual.”

Improving sector

Elsewhere, Colourgen also stocks a range of options in the direct-to-object printing market, namely from major manufacturer Mutoh. Phil Donoghue, business development manager at the supplier, says that while this area of the industry may have slowed down after the Brexit vote in June of last year, he is expecting business to pick up again in 2017.

Donoghue says: “It was quiet from June for the rest of 2016, the post-Brexit lull which many other areas of the industry experienced. With the start of a new year, we are seeing the sector slowly get busier.”

While this pick-up in business may be good for the market, Donoghue warns that companies looking to access work in this sector should invest properly in order to produce work of a high standard. And with this, he points in the direction of Mutoh and its various direct-to-object print solutions.

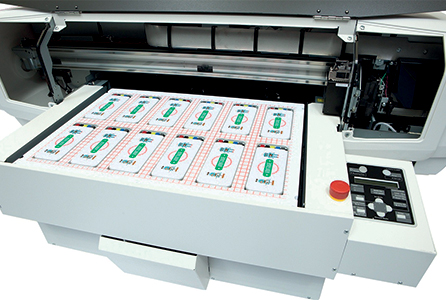

Such options include the ValueJet 426UF, a compact A3+ flatbed six-colour LED UV printer with an integrated vacuum table that can handle materials of up to 483 by 329mmm and as thick as 70mm. Speaking about this machine, Donoghue says: The printer will deliver exceptional print quality on a wide variety of solid materials and objects including ABS, Alu-board, PC, PE, PET, acrylic, PP, PS, PVC and glass.”

Available from Colourgen, the Mutoh ValueJet 426UF can print on materials up to 70mm thick

Donoghue continues: “Mutoh were third to market in this sector and as such were able to take advantage of customer feedback and produce a product that addressed market needs more fully. Price point was a concern as were elements as the requirement for extraction in some models.”

Another fantastic year

Also well established in this sector of the market is Mimaki, whose exclusive UK and Irish distributor, Hybrid Services, is kept busy with customers in the home markets. John de la Roche, national sales manager at Hybrid, believes direct-to-object printing is set for another “fantastic” year in 2017, as more innovation and technologies come to fruition.

De la Roche comments: “New inks and primers have opened up a vast selection of objects that can be printed to and the industry is beginning to explore some highly creative avenues in this sector and ‘stretch its legs’ with interior decor, personalised giftware and marketing collateral. It’s a trend that is set to continue.

“Following the release of its award-winning UJF series of small format LED UV flatbeds back in 2009, Mimaki has dominated the world of direct-to-object promotional printing, achieving an install base of several hundred machines in the UK.”

O Factoid: Mimaki’s new UJF-6042 MkII and UJF-3042 MkII can both print on substrates up to 153mm thick, and offer a 20 percent increase in productivity—in 600 x 600dpi mode—when compared to the established UJF-3042/6042 series. O

De la Roche goes on to highlight the launch of the UJF-3042 MkII and UJF-6042 MkII last year, explaining that both machines offer enhanced features, such as increased productivity, and provide compatibility with a number of Mimaki’s UV inksets.

Mimaki launched its new UJF-6042 MkII last year, alongside the UJF-3042 MkII

De la Roche says: “LUS-120 inks provide stretchability up to 170 percent and are great for printing onto soft material surfaces like smartphone wallet cases which require folding. LUS-150 inks are ideal for trophies and other acrylic items because they give excellent adhesion and the LH-100 rigid inks withstand high levels of abrasion making them perfect for accessories or stationery products.

“When used with Mimaki’s PR-200 inkjet primer, LH-100 inks are the perfect match for substrates that have been traditionally difficult for UV-curable inks, such as glass and metal. Finally, a variety of special effects can be achieved with Mimaki Clear Control (MCC) varnish ink, such as embossing or gloss finish.”

Mimaki says that its direct-to-object printing machines can handle even complex objects such as these colourful digital cameras

With plenty of options on offer in terms of direct-to-object printing technology, those companies considering a move into this sector, and indeed those already established in the market, are seemingly spoilt for choice. However, while this form of work offers plenty of rewards, as is the case when moving into any new market, it is critical that you not only establish whether you have the skills to carry out this type of work, but also if there is a demand from your customers. If the answer to both of these questions is ‘yes’, then it is time to go hunting for kit—and the options mentioned here would be a good start.

Your text here...