_3.jpg)

Trade shows have been highlighting the advances in DTG printing. Pictured: Resolute DTG at Sign and Digital UK 2015

Printing on garments has come a long way since the days of dodgy

transfers ironed onto t-shirts which start peeling off after the first

wash. A process that used to see your photo of The Clash printed onto a

black t-shirt looking more like a distressed rag recovered from the

bottom of the sea. Or old style silk screen prints where registration

might give a slightly blurred finish which added an unexpected edge to

the design.

.

Now there is a new kid on the block and it is looking to dominate the

area of garment printing in the next few years. Usually referred to as

DTG, direct-to-garment printing’s USP is its ease of set up, speed, and

accuracy.

With computerised artwork and an automated printer even one off garments

are cost-effective. In fact you can print 100 shirts each with a

variable message, so team shirts for sport, for marketing, and for

special promotions are quick and easy to handle.

Now there is a new kid on the block and it’s looking to dominate the area of garment printing in the next few years”

Digital printing began in the late 1990s and now has made inroads into

the silk screen market due to the increasing sophistication of the

process and the falling price of the machines on offer. It is cleaner,

quicker, easier to use, and requires less traditional skills to operate.

DTG is, in its most basic definition, printing onto textiles such as a

t-shirt using a modified inkjet printer. Because of the woven nature of

the material that is printed on the DTG printer needs to have an

effective transport mechanism for the garment and it must use special

inks that can be absorbed by the fibres of the material and not

immediately peel off. Darker materials also need to be primed to allow

the ink to bind with a wetting agent.

There are of course alternatives to DTG including embroidery that still

continues to dominate a niche area of the business. Embroidery dates

back to classical times because of its ability to resist washing and to

retain its form and colour for years. In the 19th and 20th centuries the

cottage industry got mechanised and has become popular with sports

badges, crests, and mottos on garments. The drawback for embroidery is

that it does not allow for photographic or intricate typeface detail

plus of course on the flip side is all the stitching—which needs to be

covered or lined so it works well on a breast pocket but has its

drawbacks on a t-shirt. However many silk screen printers will have an

embroidery unit and also a DTG printer to cover all bases.

Another rival process is dye sublimation which can use the whole t-shirt

for instance as the printing surface to create an overall graphic

finish. The dye is absorbed into the fabric blending one into the other.

This is in contrast to heat transfer printing which holds strong

details and a photographic quality but has a slightly rubbery feel and

will eventually rub off with constant wear.

Rival screen technology

Silk screen printing began back in 1910 and has moved on since then with

automated machines that can turn out high quality garments on longer

print runs. It is still in essence a traditional printing process

meaning set up times can be lengthy, while using multiple colours can be

expensive, washing up times are long, and shorter print runs are not

cost-effective. However it still accounts for the majority of the market

although year on year direct-to-garment printing (DTG) is making

inroads into its domain.

The age old rival to the emerging DTG is traditional silk screen

printing machines like this one in Austria that is still more cost

effective on long print runs

Since the advent of DTG a number of manufacturers have entered the

market in an area that has seen expansion. It has given the sign

industry a growth area to exploit as the possibilities are opened up by

the creative forces let loose by the new technology. Now it is possible

to print full colour images that do not peel on a variety of clothing.

From t-shirts to sarongs and from jackets to hats, the range of

merchandise is growing all the time with the area of corporate clothing,

marketing, sports, and leisure all offering huge openings.

The big names include Epson, Canon, HP, Ricoh, Sprint, BelQuette, DTG

Digital, AnaJet, Oprintjet, Brother, MAPI Digital, and Kornit—and of

course they offer a range of printers from entry models to larger scale

industry standards. Getting started means parting with around £20,000

for a high quality new machine, although used machines can be had for a

fraction of that price. There are printers like the Epson SureColor

SC-F2000, the Kornit Breeze, the Sprint from Anajet, or the Viper from

the USA. There are a lot of machines out there and one the best places

to try them out is at events like The Print Show in the autumn or Sign

and Digital this spring, both at the NEC.

The Viper is one of the DTG models that have proved popular

The favourite garment for silk screen printers for decades has been the

t-shirt due to its simple shape and its even and absorbent cotton

surface. It is also ideal for DTG but increasingly the range of textiles

and garments that can be printed on is growing. Leather, silk, and the

full gamut of synthetic fibres are all possible substrates.

Leather, synthetic materials, cotton, and even wool can be printed on

using direct-to-garment although materials like leather are printed

first as flat material before they are made up

A material world

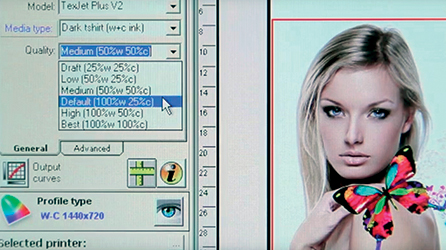

The process of DTG is familiar to anyone who has used a printer and a

computer before. First, the design is created using a system like

Indesign, Coral or Quark and from that a jpg, tiff or pdf is produced.

This is dragged and dropped into the printer’s RIP software where the

size, colours, and proportions can be edited to fit the garment’s print

surface. Once the graphic is ripped and your ideal settings are

selected, you click ‘print’ within the program, and the graphic is sent

to the printer. There is a preview setting before the printer makes a

single pass to use print in full colour for light coloured garments and

two passes for darker ones, first laying a white base before printing

using the CMYK process of inks.

The software with all DTG units is easy to master if the operator has used a PC before

Some dark coloured garments may require pre-treatment before printing so

that the white ink underbase adheres to the garment, allowing the

colours to stand out instead of being lost in the darkness of the

garment. After printing the garment needs a minute or so to be heat

treated so the ink adheres to the fibres.

Cotton or cotton blends are the materials best suited for DTG although

developments in technology have allowed for light coloured polyester and

cotton/poly blends to work. Advanced RIP software allows for driving

multiple printers from one computer including advanced job queuing, and

better ink cost calculation as it moves into an industrial scale of

production.

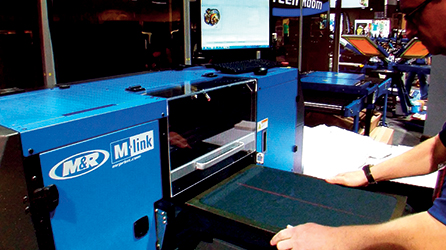

A DTG machine in action at a trade show—where an increasing number of units are now available for the growing market

At the other end of the scale DTG is ideal for small print runs meaning

that one-off items make it attractive to internet customers. Many print

firms and sign-makers have moved into this market marketing a range of

garments where the online customer can choose from a range of images and

styles or simply design their own, supplying their own artwork as a pdf

via a drop-box or similar method.

A multi-pallet DTG unit showing how mass production is possible with

some manufacturers looking to hundreds of garments being able to be

printed an hour

Rather like digital printing as opposed to offset litho printing there

is a debate about when it is more cost-effective to use DTG over

traditional screen printing. Some screen printers and sign-shops have

decided to bite the bullet and have both systems. For shorter runs

(typically t-shirts) then DTG is more cost-effective in terms of time

and money for under 50 items of clothing, while screen printing comes

into its own over 50.

Close up of a DTG unit with twin pallets doubling production time

The time factor is one that is changing as DTG gets faster and some

machines will print in a single pass first laying the white onto a dark

material and then the CMYK straight on top. Also prices for DTG continue

to fall and more of the early models are becoming available as second

hand machines so that typical break-even point of 50 shirts may well

change.

Into the future

At FESPA’s spring show in Amsterdam the latest generation of printers

were showcased including some that are a hybrid between silk screen

printing and DTG, such as the Kornit Paradigm II, while the same firm

launched two new machines, at the trade show revealing how quickly the

market is growing.

To give an idea of how their new DTG machine is working the company said

their Storm 1000 features twelve print heads in a CMYK and white

configuration and produces up to 170 garments per hour in high

productivity mode, including inline pre-treatment. It all seems a far

cry from the very first direct-to-garment printers that were limited in

their range and size. Where will the market go in the future is a

question of demand but as customers want more personalised items then

eventually it is likely that all garments and accessories will be able

to be printed by DTG.

I-Dot printer from M&R Digital with stills from a demonstration:

Preparing the shirt

Setting up

Printing the white

Laying on the colour

Out it comes

Heat sealing

All done

Your text here...