A selection of men’s gifts engraved using the Roland Metaza MPX-90, highlighting the diverse range of high margin products that can be created using such technology

Thousands of years ago, engraving was carried out using pointed tools made of iron, or sometimes with diamond points. And, until the 20th century, it remained a totally manual art, shrouded in secrecy, with masters passing on their knowledge and skills to only a few very carefully selected apprentices. However, in the mid-1900s the invention of pneumatic hand-engraving systems made the art and techniques of the process more accessible, and it became increasingly widely used for both practical and decorative applications.

Since then, automation, computerisation, and developing technology have moved the whole process of engraving to another level. Today, laser engraving machines are leading the way and have revolutionised the engraving industry. The combination of computer guidance and laser technology enables highly-accurate results to be achieved on a huge range of materials.

Making their marque

A major advantage of laser engraving machines is the versatility they provide. Designs or patterns can be easily downloaded into the machine to produce fast prototypes or production runs.

Luke Pritchett, technical sales manager at CTR Lasers, says: “You can be certain of precise engraving on every replication of your work due to the nature of the laser technology within your machine. The advantages of choosing a CNC laser engraving machine over other cutting methods are clear to see: they are versatile, precise, fast, easy to use, safe and clean, and good value for money. You can engrave a wide range of materials to a high degree of accuracy, ensuring top results every time; even intricate or complex detail can be produced effectively.”

The Northampton-based company has been producing laser-based technology for many years and offers a comprehensive service, from building machines to providing unlimited support after purchase. CTR laser engraving machines can be customised for specific applications and easily adjusted for a wide range of materials, as Pritchett explains: “One-off prototypes, small or larger production runs are all easily catered for with a laser machine.”

Two recent additions to the CTR laser engraving-cutting range are the TMX65 and TMX12 floor standing machines. The TMX 65, with a 650 x 420mmn work area, has been produced in response to demand for a machine suited to a wide range of sectors, including schools, colleges, start-up businesses, hobbyists, and many more, and is suitable as an entry-level machine for cutting and engraving a wide range of materials.

The TMX12, with a 1200 x 900m work area, is suited for those requiring a good size work area for both engraving and cutting, with higher power for faster processing.

CTR Laser’s TMX12, with a 100 x 900mm work area, is suited for those requiring a good size work area for both engraving and cutting, with higher power for faster processing

“Whether you are new to laser engraving or an expert, CTR laser engraving machines are easy to operate. Once the design software file has been imported and the laser settings adjusted, it is as simple as operating a microwave, laser printer, or CD player,” Pritchett adds.

Another player in the market is HPC Laser, which has developed a range of laser machines, from desktop models to large floor-standing machines, to suit different applications and budgets.

“Many of our customers are choosing to purchase a laser in order to do their signage in-house rather than out-sourcing,” explains managing director, Chris Jacobs.

Many of our customers are choosing to purchase a laser in order to do their signage in house rather than outsourcing”

The most popular of HPC’s range are the LS3020 Pro LSCT A4 size desktop laser, which incorporates all the features of larger lasers, such as red dot point and air assist; LS3050 Pro laser engraving and cutting machine, an advanced desktop or floor-standing model with 300 x 500mm work area; and the recently introduced LS3060 Plus laser engraver-cutter with red dot, air assist, electric rise and fall bed, USB2.0, and optional rotary attachment.

HPC also offers flatbed metal cutting lasers, capable of cutting thin sheets of stainless steel, for built-up or flat-cut lettering.

(Above and below) HPC Laser’s managing director Chris Jacobs says that lasers are a fast and efficient method of putting lines or dots on acrylic for applications such as LED lighting panels: “In terms of plastics, the polished edge from a laser cuts out a time and labour intensive process.”

Jacobs comments: “Lasers are a fast and efficient method of putting scribe lines or dots on acrylic, which allow laser cut panels and letters to illuminate evenly when illuminated from the sides.”

Getting techy

Another company offering a wide range of options is Trotec Laser, with its Speedy series of laser engraving machines featuring working areas from 610 x 305mm up to 1500 x 1250mm.

The Trotec Speedy 100 offers a compact, entry-level solution, carefully designed to meet the evolving laser engraving and cutting needs of growing businesses

Trotec marketing executive, David Dodds, claims: “Designed and manufactured in Austria, we build our machines with the highest-quality components, which assures not only the best output in the industry but also the longest life-span and lowest cost of ownership of any laser in the world.

The Trotec Speedy 500 is designed for those who require fast processing of large volumes and large surface materials

“Our machines are built to last, and the innovative design of our laser systems reflects our desire to increase our clients’ profitability while keeping the total lifetime cost of the machine down. Our latest Ceramic laser cartridges outperform every other laser source. They are particularly outstanding when stacked up against traditional glass tubes, which fracture frequently and require replacement, eating into your budget.”

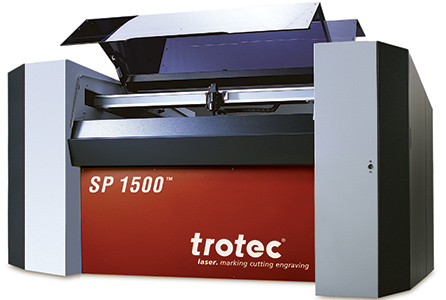

The Trotec Speedy 1500, with 1500 x 1250mm work area—the same size as a standard acrylic sheet, offers high productivity combined with low maintenance costs

This technology, known as CeramiCore, is environmentally-friendly too, with the company’s benchmark tests showing a reduction of up to 30 percent in energy consumption when compared to an older-style laser source of the same output. Trotec has also made vital protection of the electronics and drive train as an integral part of its designs, so that the lasers maintain their efficiency and reliability with the minimum of attention and cleaning, a ‘must’ to protect your investment, according to Dodds.

He adds: “We weren’t content with just making the fastest lasers. We also wanted to make the most productive. Material is expensive and as such we’ve integrated several features into our systems to ensure that you get the maximal possible use out of them.”

Looking to Roland DG’s engraver family, it includes the EGX-30A, which the company recommends as ‘the perfect engraving starter package’. It comes bundled with tools and cut 2D software for plug and play simplicity.

It is also quiet and can potentially be run from an office, shop, or even from home.

Roland’s EXG-350 engraver is capable of producing a wider range of products from brass plaques to corporate and personal gifts, indoor signage, jewellery and awards, with crisp texts and clear graphics

Also in the EGX family is the EGX-350; Andrew Dudley, business manager, 3D and consumer, Roland DG (UK) explains: “This is a highly-versatile machine, which offers cost-effective batch and single unit production and is capable of producing a wide range of products from brass plaques to corporate and personal gifts, indoor signage, jewellery, and awards with crisp texts and clear graphics.”

In addition, for intricate engraving on metal Roland DG offers the low-cost and easily-portable Metaza MPX-90. From just a scanned image, it can output photographic-fine engravings on even industrial materials, such as stainless steel and brass, as well as gold and silver.

Roland’s Metaza MPX-90 impact engraver is ideal for intricate engraving on metal, with a capability to output photographic-fine engraving on even industrial material such as stainless steel and brass as well as gold and silver

“The MetazaStudio plug-and-play software that is supplied as part of the package makes the MPX-90 as easy to use as a printer,” adds Dudley.

Over the past 20 years, Warwickshire-based Gravograph has developed a complete range of C02, YAG, and fibre lasers, which come complete with its own specialist lasering software, LaserStyle7, supplied as standard. Machine manufacture and software design are undertaken in-house and the expertise and knowledge of the company’s team located across the UK is readily available to support its customers.

O Factoid: The first evidence for humans engraving patterns is the hatched banding on ostrich egg shells (used as water containers) that were found in South Africa, in the Diepkloof Rock Shelter, and dated to the Middle Stone Age, around 60,000 BC O

The latest addition to Gravograph’s range is the LS1000XP, with a 1,220 x 610mm work area and lasering speed capabilities of up to 4,000mm/s. Its front loading design enables items of up to 250mm high to be accommodated, and the laser head is fitted with air assist for cutting, intelligent LED pointer for positioning, smart sensor for auto-focus setting, and optional fume extraction.

At the ‘sharp end’

So what does this mean for those of you working at the ‘sharp end’? How does all this translate into benefits, income generating opportunities, and profitability for sign-makers? Here is the verdict of some of our manufacturers: “Lasers offer personalisation throughout signage, including company logos, brand image, exhibitions, point-of-sale, and window displays,” says HPC’s Jacobs.

“Recently we have found the sign-making market to be experiencing increased growth in the laser industry. Owning a laser machine will not only improve performance, it will boost productivity, and save you time and money. And, in terms of plastics, the polished edge from a laser cuts out a time and labour intensive process.”

Roland DG’s Dudley suggests: “Roland DG’s wide selection of highly-versatile engraving machines are capable of engraving just about any substrate including plastics, brass, glass, aluminium, metal, and wood, which makes them an ideal proposition for sign-makers looking to create new income streams for a comparatively low level of investment.”

An ideal proposition for sign-makers looking to create new income streams for a comparatively low level of investment”

Summing up, the last word goes to CTR’s Pritchett, who concludes: “Because laser engraving is faster than traditional techniques, you can achieve greater output and increased productivity, giving you a better return on your investment and ultimately leading to more profitability.”

Whether you are looking to dip a toe in the water or build on an existing service, there is a wide range of kit available to suit an equally wide range of budgets. And with the increasing demand for engraved signage, whether for practical requirements, to create a different and more individual effect for business branding, or for purely decorative or artistic applications, it is surely an area worthy of a second look for sign-makers.

Your text here...