Exeter Signs created this Rallycross racer’s graphics for the Monster team using only materials from Ritrama. Gloss Black was used for the main wrap, with detailing created using Matt Military Green. The decals were digitally printed using Cast 50 White and over laminated with Flexilam 30

Red Hot Racers

There is perhaps no other sector in the sign industry quite as sexy as vehicle wrapping. It has certainly become something of a fashion cult across the UK, with everything from commercial vehicle fleets to souped-up track beasts seeing their bodies decorated with colour change, special effect, and digitally-printed wraps and stickers. Even this writer has fallen foul of the trend to add some personality and pop to his much loved and battered Japanese hot hatch, adding racing numbers and decals to lift its tired 20-year old paintwork. Indeed, anyone who read SignLink May’s special Tech Buzz section on page 48, which documented the research and development of LG Hausys’ latest products, will know that the competition between manufacturers in this sector is seriously heating up as they jockey for position and market share.

One supply company that has diversified into this sector and grabbed its potential with both hands is Greenstik Materials, which has a historic relationship with Ritrama and stocks its digitally printable Ri-Jet 50 and Flexilam 30 overlaminating film as well as the RI-WRAP Carbons, Matt, Textured, Chrome, Metallic, Pearlescent, High Gloss and Vehicle Protection films series which spans literally hundreds of individual options. It also stocks some very special options that allow those car enthusiasts bent on full personalisation to wrap the interior trim of their vehicle with a range of wood-effect options, brushed metal, and textured effects.

With all this choice, the company’s General Manager Brett Gregory explains his passion for this colourful and creative sector: “We have been running this arm of the company for two years now. Where we fit in and are different is we have done a huge number of tests and mock wraps on our own vehicles so we can work closely with our customers to help them get the very best out of each material and design. When a vehicle wrap or customisation works, it is really some-thing special.”

APA has a wide choice of core colour vinyls and digitally printable cast films. The company’s area sales manager James Deruvo explains that it is the Italian company’s cultural fashion and automotive legacy that has seen it focus on creating products of the highest quality that allow consumers to express their creative flare

Commenting on the latest developments from Ritrama to look out for, Gregory explains that the company had made sure that quality is core to the company’s research and development ethos: “The entire range with the exception of two speciality polymeric options are all full cast films. They are all fully conformable for automotive applications and have special air-release adhesive systems to make application and removal really efficient. They have also very recently launched a range of marine-grade films for wrapping yachts and power boats above the waterline, which necessitates very high levels of adhesion and durability.”

O Factoid: Among the very first digital print and cut vehicle wraps were in the USA for bus advertising, where vinyl for interior decoration was adapted and printed onto using the first generation of wide-format digital printers, cut into strips and applied using liquid adhesives. O

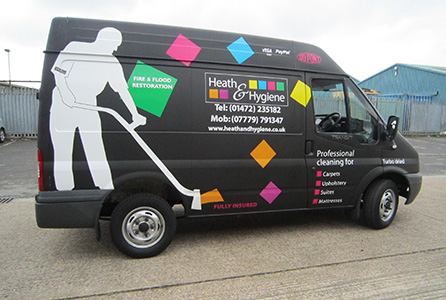

Another key trend that is shaping this sector is the growing demand from the UK’s huge racing industry. In years gone by a race car would have been wrapped and left for a season unless damaged. Today race teams from Rally Cross to Formula 1 want new wraps for every meeting. This has been a massive boost to many sign-makers and wrap specialists who have tapped into this lucrative area. Once such customer of Greenstik is Exeter Signs, who has secured the contract to wrap the super-sexy souped-up hot hatches of the Monster Rally Cross team.

Gregory continues: “The demand from the UK’s racing fraternity has certainly seen the volumes of vehicle wrapping films being sold increase year-on-year. If a sign-maker bags one of these contracts then it really is something of a lottery win, as they will want funky designs and complicated graphics layers to make them, and most importantly their sponsors, stand out.”

If a sign-maker bags one of these contracts then it really is something of a lottery win”

He goes onto explain that one of Ritrama’s flagship products is its fully-printable RI-WRAP Cybershield Silver and the Cyberkrome range available in Red, Green, Yellow, and Blue. The full RI-WRAP range features Ritrama’s ‘Airflow’ air release adhesive that helps to eliminate bubbles in application, even on entry-level products for flat to slightly curved areas such as Carbon Flat Black. The chrome products are capable of around 25 percent stretch against a standard cast film due to the special finishes, which Brett explains is more than enough if you had proper applicator training to tease and tweak the material over moderate curves and slight recesses.

Gregory concludes, explaining how the latest innovations on the market are shaping it: “The real differentiators between vehicle wrapping films now is the adhesives and coatings. Each manufacturer worth its salt has its own patented adhesive system that allows todays films to be applied without leaving unsightly bubbles that need popping, don’t have high levels of initial tack so they can be applied easily, and can be removed at the end of their life without leaving lots of residue or damaging the paint work.

JCody Signs created this visually innovative wrap using Metamark MDX. Proprietor James Cody explains that today’s vehicle wraps demand high levels of creativity and understanding of the best materials to use for individual projects

“With their own manufacturing plant, this means Ritrama are ahead of the game in terms of how quickly they can bring innovations to market. They really are a dark horse, because while perhaps not the best known brand yet, their products are best-in-class in terms of quality. They have a good range of choice and the ability to colour match films with a lead time of 6 to 8 weeks, but they haven’t quite had the exposure they need until now. So our mission at Greenstik Materials, as the main Ritrama UK certified RI-Wrap distributor, is to try and educate the industry about the creative and revenue generating potential of these products.”

Pushing boundaries

Gregory’s point about manufacturers being ahead of the game if they have the ability to develop their own systems from scratch is an advantage shared by Metamark. It has built itself an enviable reputation in the sign-making and wide-format print industry as being one of the players at the very cutting edge of innovation when it comes to digitally printable vinyl for vehicle wrapping. Its latest flagship range is its 50 micron ultra-extensible MetaWrap MD-X film. This is designed to remove any limitations when it comes to the design of digitally printed wraps, as it can adhere around very tight curves and recesses without any damage to the print.

Looking like something straight out of The Fast and The Furious, JD Wraps used 3M 1080-M196 Matte Apple Green to turn a normal VW Golf into this sexy boy racer

“The sparkling gem at the centre of this subject is the market itself,” says Max Somper, Metamark’s Woking distribution centre general manager, adding: “Wraps tend to promote themselves, as heads turn when you see a real good one coming down the road. This has created something I like to call wrap envy. This is when you see a really good graphic on, for instance, a van. It makes a business owner realise they need to up their game on their own fleet.”

The sparkling gem at the centre of this subject is the market itself”

He continues: “The next factor is that the skill needed to create a really good design that spans a whole vehicle is much more complex than being able to apply print-and-cut vehicle lettering. The other factor is that the economics of setting up a wrapping wing requires careful thought and planning, as it requires higher levels of investment in regards to equipment, training, and staff to be done properly.”

Somper goes on to outline that this was the key motivation for the development of products such as MD-X, because it helps to reduce barriers to entry into the sector. He explains its ease-of-use and quality means that very high-quality wraps can be achieved without the years of practice and knowledge that was needed for older generation products on the market.

Somper also highlights another vital element that sees the latest generation of vehicle wrapping films such as MD-X make a significant impact on the market: “The price point of this development really does alter the business argument for founding or expanding a wrapping division. It opens up the market and the opportunity for wraps that, while they will last for years, can be changed much more frequently.

Custom Coats used 3M 1090-M38 Matte Purple to transform an Audi RS5 from an everyday sporty hatchback into a real head turner. Picture courtesy Daniel Romani, Subtle Sensor Photography

“A year ago something like a temporary promotional wrap may not have been on your customer’s agendas, because it was a very expensive undertaking. Today you can produce a wrap for a customer they only need for three months because the economics bear out that possibility, whereas previously they didn’t.”

Described as, ‘a next-generation plastic for a digital age’, Somper explains that MD-X prints, ‘like any other Metamark MD class product’, but has conformability to rival that of any product on the market. He also highlights it is as easy to use when laminated as without a protective covering, something that has been a bug-bear of wrappers for years.

Somper continues: “Even partial wraps, perhaps just down the sides or the bonnet and roof, increasingly need vinyl being fitted into tight recesses as vehicles bodies designs become more complex and curved. So, we have a market that is seeing the demands continuing to increase on the wrappers skills, the economics of wrapping, and the materials. Our mission with products such as MD-X is to continue to meet those demands as they evolve.”

Somper goes onto emphasise that it is how its new MD-X films perform once they are ‘hosed down with ink’ that is of key importance. This is because older generation products can become fragile once printed with a full-colour design, while this ‘next generation’ product is able to much better flex and stretch while heavy with ink. Another facet is the all-important patented METAScape adhesive that Somper says allows for, ‘rapid and frequent repositioning while continuing to stick when needed and build to a great bond, despite the bullying needed to get into the deepest recesses’.

Somper concludes: “Metamark regards wrapping not just as another area to be covered, but one that requires very specific attention. And so we create products that satisfy and exceed the very specific needs of the market. They are developed by design to work with a very demanding process that is technically challenging, but commercially very significant, whilst also removing historical bottlenecks from the process such as cost and difficulties with application.”

Mambo Italiano

One of the most exciting aspects of the vehicle wrapping market is the ability to turn a customer’s wildest expression of individuality or marketing message into reality, wrapped around a vehicle. Founded in 1978, one company that has fashion, creativity, and flare built into its DNA is APA. In addition to a core range of cast films and laminates for digital printing and colour change, the company has a truly amazing range of speciality films from crocodile effect leather to jungle effect camouflage.

Speaking to its sales area manager, Francesco Deruvo, he explains what has motivated its approach to product development: “Our core market is sign-makers and graphics shops, and what has really distinguished our company is that we are a more focused, creative, flexible, and design orientated company in the best Italian tradition.

“Italy as a country is well known for its high quality in areas such as fashion and vehicle manufacture, just mentioning a few names like Gucci, Prada, Ferrari, and Lamborghini proves my point. We have always been a very creative people and we embrace this cultural legacy with our products.”

Deruvo continues: “When it comes to vehicle wrapping, I am proud to say that APA was a pioneer in this industry. We were one of the very first companies to focus on developing colour-change vinyls and special adhesives that suited the demands of car wrapping. Sign-makers first started out using normal self-adhesive PVC and applying it to cars but we saw the potential and so committed ourselves to developing this technology.”

Deruvo explains that such is the emphasis at the company of creating solutions that meet the demands for personalisation that, for example, it has created four different types of black carbon-effect films. He adds that the company has also made sure that its speciality products also tick, ‘every box’, when it comes to usability and durability.

He concludes: “It is important to know that APA is a growing company. Historically we were focussed on the Italian market, because it was our home territory. Over the last few years we have made significant moves into foreign markets like the UK, built our dealer networks, and now have substantial market share.”

Looking across some of the latest developments from APA, it has also brought to market its own Chrome product, which importantly is PVC-based and thus allows for increased conformability. Deruvo also marks out that effects such as camouflage, new-buck leather, denim, and zebra waves are selling well in the market.

Indeed, such is the growth potential of vehicle wrapping films that core sign material suppliers such as Fujifilm Euromedia with its 3DSmartApply digitally printable film with matching gloss laminate and Antalis with its Orafol range have also got in on the action with the release of films to suit specific demands and also tap into a huge satellite consumables market. Another very notable developer who has been bringing exciting speciality and digitally printable vehicle wrapping products to market is Arlon, distributed in the UK by William Smith.

Antalis’ sign and display product manager, Michael Crook, comments on the trend: “We are seeing growth within this market, as the quality products and superb advice and tools that work alongside the base material are of the highest quality—making the entry into this market straightforward, or the switch from an equivalent product seamless.

Antalis stocks German manufacturer Orafol’s range of vehicle wrapping films and laminates, with market expert Michael Crook explaining that the market will only continue to grow in line with fashion trends that are seeing everything from phones to Smart Cars personalised

“For vehicle wrap applications the Orajet 3951 and Orajet 3951RA provide true high performance cast vinyls—RA being the rapid air adhesive technology for ease of application.

“Orafol have recently launched wrap cleaning wash along with two kits, one for gloss and one for matt vinyls, which provide all the preparation and cleaning agents to work alongside the quality 3951 digital and 970 colour change vinyls and matching Oraguard 290 and 293 laminates.”

Boy’s got skills

The UK sign and wide-format print industries are somewhat blessed when it comes to the number of companies that are headquartered on our small island that develop their own ranges of vehicle wrapping films. Another core player in the sector is Tamworth-based Grafityp, which echoing the comments from Metamark’s Somper, has helped lead the charge in making sure its customers have the skills and tools needed to create the perfect wrap.

Spearheading this effort for the company is renowned expert James Deacon, Grafityp’s wrap training specialist and owner of wrapping company Bigger Stickers. He explains that the best materials in the world will get you nowhere if you do not know how to get the best out of them: “Some newcomers will tend to blame the media if a job goes wrong. A film can only do so much, and if you haven’t taken the time to learn you can fundamentally be applying it in the wrong way.

“We have been running wrap training courses for more than ten years now, and today Grafityp has a purpose-built centre to help attendees get the very best out of the experience. It houses a Smart Car, Mercedes Sprinter, and a number of highly complex vehicle panels to put the materials and ‘students’ through their paces. This is necessary because the quality demanded from wraps is higher than it has ever been, and it is not something you can just jump into and hope for the best.”

Grafityp has an extensive portfolio of vehicle wrapping films that are turning heads due to their ease-of-use, durability, and eye-popping creative potential

Deacon continues: “The biggest change in the industry has been that now even the smallest wrap shop will own a digital printer capable of high quality prints. This has spurred the development of vinyls, both in terms of retaining flexibility after printing, but also in how easy they are to use with the development of air escape films to make application easier. The printers also have a wider colour gamut with six-colours now standard on many systems, and also options such as speciality metallic inks.”

Looking to Grafityp specifically, Deacon explains it has brought to market several innovations such as the recent addition of a cast metallic and matt laminates for digital prints. The firm has a full range of special effect and digitally printable films both cast and polymeric such as cabon fibre, through camouflage and leather, to velvet flock. It also has a unique range of creative options in its Stardust and Art Deco range, with evocative names in the latter like Galatica and Antarctica.

Deacon concludes by highlighting a key trend that is seeing the prices for vehicle wraps come down, while profit margins are still going up. While this may sound counterintuitive, it is because innovations from companies such as Grafityp and its peers has meant wraps can be applied much faster, at higher quality, with materials that cost lest.

Giant aspirations

Looking to the wider market, perhaps two of the biggest historic names in wrapping are Avery Dennison and 3M. Indeed, the two companies have committed a large portion of their substantial multinational research and development budgets to evolving their products in this sector. The latter has perhaps made greater strides in marketing itself in the UK, even creating its own mini wrap economy of 3M Certified Wrappers who feedback information on the fashions and requirements in the market to steer development of new products.

It has also been able to generate demand for its products directly from consumers as a fashion label in its own right—not waiting for sign-makers to choose or suggest their products. Indeed, increasing numbers of car enthusiasts from boy racers to super car owners will now specifically request a ‘3M Wrap’, even retaining the logo as a digitally printed badge of honour. Speaking to the company’s trade marketing manager for its Commercial Graphics wing, Richard Davies, and its marketing executive, Paul Kitchen, the dynamic duo highlight some key trends influencing the development of vehicle wrapping films.

“While there are a large number of speciality products on the market for the consumer side of the business, we are still seeing the highest demand coming for core colour change products such as satin black or gloss white. It really is 80 percent of our sales coming from 20 percent of our most popular colours,” says Kitchen, who adds: “But it is about being a shop window for the market and developing all the speciality effects and colours possible. A sign-maker’s customer may not want to go with a pearlescent blue or matt orange now, they may initially choose a brushed steel, but the option is there and will be taken up when they want to do something more unique.”

It really is 80 percent of our sales coming from 20 percent of our most popular colours”

Davies chimes in: “From the commercial side of the business, when it comes to colour change, the majority opt for core colours and shy away from speciality effects. But again, there are those brave few that need these options for specific creative marketing campaigns or one-off initiatives. The trend towards personalisation is a major factor in the development of vehicle wrapping films, with new colours, textures, and special finishes now being driven rapidly by consumer taste and for us it is about keeping on top of that.”

Considering its history when it comes to excellence in technology development it is not surprising that 3M has brought a number of clever innovations for wrapping films to market. One of these is its patented Controltac adhesive, which allows you to glide the film over the vehicles surface with almost no friction until the registration is right and you want it to stick by applying pressure. Kitchen explains this is not a ‘low-tac’ adhesive, which can take 48 hours to cure properly. Rather it uses microscopic tunnels that contain the adhesive and provide no stick when the backing film is removed. When pressure is applied however, it allows the glue to be pushed up and out through ‘posts’ in the tunnels to provide the bond—a key advantage that allows for very rapid graphics application and curing. 3M has also developed its special Comply v3 adhesive, which further enhances speed of application with a channel adhesive system that allows for bubble free application. Most recently the firm has added five colours to 1080 series of films, bringing the total number of colours available to 55. The new colours in the series comprise gloss charcoal metallic, gloss blue steel metallic, matte dark navy, satin white aluminium, and matte deep black.

So, if you thought you had a pretty good steer on the vehicle wrapping market and the products on offer then think again. What is very clear is that the innovation and competition in this sign-making product sector is only going to intensify, and that is very good news for sign-makers and wrap specialists as it will serve to drive up quality, drive down prices, and ultimately make for a market sector rich with possibility for a long time to come.

gggg