(L to R) Professor David Serlin and Vogue critic Sarah Mower in a ‘dress to protest’ session at Port Eliot Festival, on a stage printed using Epson inkjet

Get ready for some uplifting bright florals, gothic architecture

inspired fabrics, and a sportswear jacket that does far more than meets

the eye; this month we are delving into the fashion world and the impact

of wide-format printing technology on the industry.

Having noticed the sheer amount of fashion related printing stories, we

here at Print Monthly thought it was only right to dedicate a whole

feature to the topic. The capabilities of printers these days is

certainly allowing designers to be bolder, more creative. In some cases,

bespoke handcrafted work is actually taking a backseat in favour of a

move to using printed designs. These are all made possible with the

latest technology, from printing manufacturers both yourself and I have

read about in this very magazine.

Take Epson, for example. The print giant was the chosen manufacturer for

fashion designer Richard Quinn when tasked with decorating a stage at

Port Eliot Festival, held in Cornwall in July. The festival celebrated

words, music, fashion, nature, and food. One stage, called The Wardrobe

Department, hosted interviews with design legends, and was designed and

produced by Quinn.

Richard Quinn on the set he designed and printed for Port Eliot Festival using Epson inkjet

In his new studio, Quinn used Epson’s Sure Color SC-F9200 to print Mylar

metallic wall coverings and Premier Textiles furniture fabric for the

festival stage. Quinn was even interviewed on stage about his new

collection to be shown later this year at London Fashion Week.

“Being invited to create a unique, one off set for the festival was such

an exciting prospect,” says Quinn, adding: “Although initially daunting

because I had to create so many appropriate surfaces and textiles for

the set, the Epson technology, its ease of use and multiple available

substrates made the task straight forward, cost effective and achievable

in a short time frame.

“My design and print is all about the colour vibrancy and the Epson

technology allowed me to get the desired Pantones with ease across all

the substrates. The Sure Color SC-F9200 has been so efficient for our

fashion line and this was the first time exploring upholstery fabrics—a

great success. The Epson option for a 4 pass plus 30 ensured the thicker

pile fabrics are as vibrant as others, making the Parker Knoll

furniture really pop.”

My design and print is all about the colour vibrancy and the Epson

technology allowed me to get the desired Pantones with ease across all

the substrates”

Richard Barrow, senior product manager at Epson Europe comments on how

more designers are seeing the capabilities of Epson technology: “It is

very exciting how Richard is exploring the considerable flexibility of

digital print to take his designs onto a wide variety of substrates. He

is leading the vanguard of new young designers who are taking advantage

of the considerable power of digital to create new opportunities and

businesses.”

High in demand

On top of this, students from Birmingham City University’s (BCU) School

of Fashion and Textiles recently demonstrated the flexibility of Epson

inkjet by producing home furnishing designs with the technology.

The Sure Color SC-F wide-format dye-sublimation printer and desktop Sure

Color SC-F2000 direct-to-fabric printer take pride of place in the

university’s digital print suite and are said to be ‘high in demand’ by

students.

Designs for items such as wallpaper, sofas, cushions, and lamps were

created using the printers and were also displayed at FESPA in Germany.

However, Epson did not just recommend the printers and leave the

students to it; the company is keen to educate the younger generation so

they can have as much success as possible. As part of the project, the

students attended a colour management workshop at Epson UK’s

headquarters to gain skills that will help them maximise the quality of

their designs.

Epson awarded Shannon Keenan, a BA (Hons) Textile Design graduate, with a

‘Creativity in Digital Print’ award for her project combining satin and

diaphanous textiles, surface embellishments, and Sure Color SC-F

digital print to produce fabrics inspired by gothic architecture.

“Working with Epson has been brilliant for the students, showing them

the skills and considerations required for commercial print production

in relation to our own fabulous facilities,” says Kate

Shannon Keenan created fabrics inspired by gothic architecture using Epson’s Sure Color technology

Farley, lecturer in Textile Design at BCU, adding: “Epson’s generosity

in supporting the course in a number of ways shows how mutually

beneficial these partnerships can be.”

Heather Kendle, market development manager at Epson Europe, adds: “Since

Epson started working with BCU, we have consistently been impressed by

the quality and creativity we have seen from the students. The ability

to combine print with other elements is what came through in Shannon’s

work, as well as her attention to detail and understanding of what a

commercial brief may require.”

Opening doors

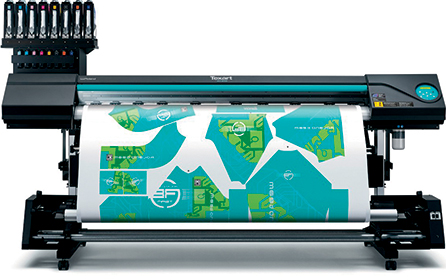

Hybrid Services, exclusive UK and Ireland distributors for Mimaki, has

spoken out on the impact Mimaki printing technology has had on the

fashion industry. The company continues to drive the digital fashion

printer sector, with many textile machine launches at this year’s FESPA.

It highlights its TS30-1300 dye-sublimation printer as the ideal entry

level solution, costing £7,495.

Brett Platt, textile product manager for Hybrid Services, says: “The

TS30 will open doors to fashion designers and studios thanks to its low

cost and ease of use. It offers unique features such as eye-catching

fluorescent inks and gives fashion professionals a tool that brings

print to life. For sampling purposes, it is no longer good enough to

present a fashion design idea on paper and the TS30 makes it

cost-effective to show compelling samples or even made up garments on a

range of different polyester fabrics.”

Platt also highlights Mimaki’s three production textile printers, the

TS300P-1800, Tx300P-1800, and Tx300P-1800B. He says: “With the 300

Series textile and dye-sublimation printers, Mimaki has the strongest

offering available and the take up from fashion companies, universities,

and design studios has been significant. The recent launch of the belt

fed Tx300P-1800B has enabled cotton jersey, very lightweight silk and

other more challenging textiles to be printed to, whilst retaining

ultrahigh print quality thanks to its stable fabric transport.”

Mimaki also launched the Tiger-1800B this year, which Platt says is

capable of bringing “fast fashion” back to the UK, for example, when

producing limited edition clothing collections.

Platt concludes: “Our printers are used by up and coming university

students to show their final year portfolios, small fashion houses to

produce one-off dresses for discerning clients, large print providers

who serve many of our high street retailers with exciting, high fashion

product lines, and global designers looking for a runway piece that will

appear in the pages of the latest magazines. As a hardware distributor,

there has never been a more exciting time to be involved in the fashion

industry.”

One establishment that has invested in Mimaki’s TX300P-1800 textile

printer is Heriot Watt University’s School of Textiles and Design. Its

25 final year Design for Textiles students were able to output designs

onto a range of fabrics for their degree show.

Mimaki’s TS300P-1800 printer has had significant take up from fashion companies and universities

The TX300P-1800 is a 1.8m wide textile printer which can print on

cotton, silk, wool, and polyester—providing plenty of choice for fashion

designers. The machine has a production speed of up to 55sq m/h and is

ideal for short to medium run production, especially to produce items

such as furnishings and other textiles.

“Our existing Mimaki printers have served us well for over 10 years but

with the added capacity of the new Tx300, we’re able to more efficiently

deliver the long runs required by our students for their final year

collections,” says senior technician, Dr Roger Spark.

He continues: “We offer the potential for not only the Design for

Textiles undergraduates to print their work but also the provision of

printed fabric for our Fashion students to make into garments in our

sewing workshops.”

Spark also notes how the Tx300P-1800 has fitted into their print room “perfectly”.

Mimaki’s TX300P-1800 textile printer was used by Heriot Watt University students in their degree show

Hybrid Services’ national sales manager, textile and apparel, Stephen

Woodall, comments on the use of the Tx300P-1800 at Heriot Watt

University: “This is one of the very first of the new printers to be

installed in a university and it’s great to see students benefiting from

the absolute latest textile printing technology. Heriot Watt’s

undergraduate textile courses offer a unique and valuable opportunity

for prospective fashion designers to experience industry standard

equipment and processes.”

Winning gold

Of course, there are many different areas of fashion, from children’s

wear to costumes. Another area is sportswear, which as a sector requires

not only style but practicality. Kayaking apparel company, Peak UK,

spent four years making its Racer ST garment by combining a jacket, life

jacket, and spraydeck into one item. The combination reduced the

thickness of the life jacket by 20 to 30mm, and reduced the overall

weight of the jacket, resulting in increased speed for canoeists.

Peak UK founder, Pete Astles, explains: “From the very early stages of

the initial idea, we knew we had a completely unique and groundbreaking

piece of kit that could give athletes the edge over their competitors.

With the Rio 2016 Olympic Games coming up, we decided to approach

British Canoeing and explore the possibility of supplying the kit for

the athletes.”

O Factoid: Port

Eliot Festival posed interesting debates about whether fashion can be

utilised as a form of protest. It showcased ‘Cancel Brexit’ t-shirts

designed by Katharine Hamnett, where proceeds from sales will support

the Cancel Brexit campaign. O

British Canoeing were won over, and entered a partnership with Peak UK

to become official suppliers of the kit at the Olympic Games. However,

having only produced prototypes of the garment by hand, Peak UK needed

to invest in technology that would allow them to put Team GB’s branding

onto the product.

Astles adds: “We were instantly drawn to the Roland DG Texart RT-640

dye-sublimation transfer printer because it was more industrial and

robust than its competitors, with the open design making it easier to

service, clean, and maintain. We quickly got to grips with the machine

and one year later, we still cannot fault it. The machine is truly

faultless, effortlessly printing high quality prints to the extent where

we have not had one bad print.”

Peak UK founder, Pete Astles, says after one year with Roland DG’s Texart RT-640, he “still cannot fault it”

The Texart RT-640 from Roland DG, with its printing resolution of

1,440dpi, is said to be ideal for sublimated sportswear, soft-signage,

fabric for fashion, apparel, décor, and promotional goods.

Team GB athlete Joe Clarke, who wore the Racer ST garment at the 2016

Rio Olympic Games, went on to win the gold medal in the K1 men’s

individual. Clarke praised his thinner life jacket for providing the

“marginal gains” that made his win possible.

Peak UK created a unique sportswear jacket with the

help of Roland DG technology to add Team GB’s branding. Pictured:

Olympian, Fiona Pennie

So, wide-format printing technology is having a huge impact on fashion,

enabling designers to be more creative and even helping students in

their first steps into the fashion world. Furthermore, when designers

such as Richard Quinn are gracing the pages of both Vogue and Print

Monthly, it is clear the two worlds are closer than perhaps perceived.

Your text here...

Your text here...