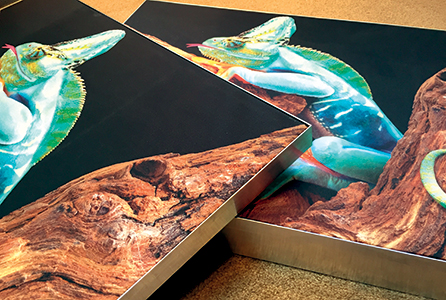

Décor Mark digital print wallcoverings are designed to create durable, colourful results that can be applied to virtually any sound interior surface. Pictured: Andy Graphix produced this commission for a child’s bedroom redecoration

With the speed at which sign-making materials continue to be developed to meet an ever increasing spectrum of markets, an overview of the latest innovative products can only be equated to a balance sheet—a snapshot of where we are at this particular point in time. By the time you are reading this, more new materials will already have been launched or in the pipeline.

Printable materials are the staple fare of any sign-making business. However, recent years have seen significant and rapid developments in these products, providing sign-makers with a veritable feast of options. Textiles and interior décor materials in particular have been making inroads into a domain where vinyls once held sway, and thereby opening up whole new areas of business for those with a mind to pursue them.

As a leading manufacturer and distributor of printable materials, Soyang Europe offers a broad choice of innovative

substrates within its extensive portfolio of wide- and grand-format materials. These range from non-slip printable aluminium floorcoverings, textured wall décor, and recyclable textiles to frosted self-adhesive films, non-curling pull-up banner, and even printable carpet.

The latest Decal range from Soyang Europe is resin adhesive coated, which gives the product very high tack properties, with reduced shrinkage and a glossier finish

However, the firm’s sales manager Kerrie-Anne Moore is also keen to highlight substantial advances that have been made in more conventional products.

“The Decal range of self-adhesive vinyl scores on several points,” says Moore. She adds: “Decal is the only range in the market that is resin adhesive coated, which gives the product very high tack properties, with less shrinkage than other PVC films and a glossier finish.

“We’re keen to deliver added-value in every product we offer at Soyang Europe. Whether it’s a premium grand-format fabric or something as straightforward as a self-adhesive vinyl; giving our customers an advantage is paramount.”

The Decal line-up also includes a variety of wallcoverings, which answer an increasing demand for printable décor. “An important feature of our So Decor product range is that it’s printable with solvent, latex and UV wide-format printers,” states Moore, who adds: “With a selection of textured finishes, and multiple adhesive options, it provides sign-makers with a highly creative range of materials with which to deliver bespoke décor for commercial and domestic clients.”

Metamark also has new offerings for both signage and décor applications. MD5 is a high-performance grade polymeric calendered print film that is suitable for application to flat or slightly curved surfaces, making it ideal for vehicle graphics, retail signage, and window graphics. Metamark says that the combination of high quality film, adhesive, and liner, together with Metamark’s distinctive coating technology provides outstanding print

performance.

A moveable feast

Vehicle livery work also represents one of the most extreme applications for printed and applied digital graphics. Exposure to aggressive cleaning regimes, the ravages of every type of weather, and inevitable knocks and bumps too, means that livery that endures and performs well in such conditions is valued and sought, especially by big brands that want to promote consistently high standards.

One such brand, Brace’s Bread, recently sought out Gary Bagstaff and his team at Print Sauce in Caerphilly to lift the profile of its fleet with some genuinely head-turning livery work. Although Brace’s Bread has been baking since the early 1900s it is a truly state-of-the-art business, as its fleet reflects.

Metamark’s MD5 high performance grade polymeric calendered print film helped Print Sauce deliver head-turning vehicle livery for Brace’s Bread

One job that Print Sauce delivered for Brace’s involved a logo emblazoned across the whole expanse of a trailer. With strong geometric image elements radiating from the design’s central point of focus, and cutting through numerous panel edge lines, perfect application was essential. Panel to panel colour matches also needed to be critically managed so as not to interrupt the transition of tone and print density.

Bagstaff, therefore, turned to a proven material and print technology partnership to produce the livery. He used Metamark MD5 printed on an Epson Sure Color printer.

“The printer and material combination performed brilliantly,” affirms Bagstaff, who continues: “MD5 tolerates big ink loadings and resolves detail to the degree we needed to deliver the flawless gradation and inter-panel matching. The finished result is a livery that really does turn heads.”

Also a fairly new addition to Metamark’s portfolio is Décor Mark, which prints like MD5 but addresses a whole new range of opportunities. Décor Mark digitally printable wall coverings are designed and formulated to print like Metamark MD5 and to create durable, colourful results that can be applied to virtually any sound interior surface.

“With a digital printer in the workshop and access to this innovative new range of digital media, sign-makers everywhere are discovering that the design and application talents they already possess can open new doors into the commercial décor sector,” explains Metamark’s chief executive officer, Paul French.

“Applications for the Décor Mark range are opening new commercial possibilities for sign-makers in retail and leisure markets. Commercial office spaces are also benefitting from the versatility of the media, and it looks as though the long-standing dominance of emulsion paint finishes in premises as diverse as hairdressing salons and gyms may be seeing out its final days too,” French elaborates.

“Décor Mark is easy to work with, as the product has a good appetite for ink which makes it straightforward to print, with printed detail fully resolved and colours deeply saturated. The materials dry readily and have absolutely vice-free handling characteristics which make printed output easy to apply and fit; and once applied, Décor Mark materials are long-lived and retain their attractive finishes,” claims French, who adds: “The textures are designed to be sympathetic to the light sources they’ll typically encounter when applied, and impart qualities that reflect the need to add interest to large expanses. The materials are also tough enough to withstand the effects of the kind of life encountered in busy premises without picking up obvious damage.”

Metamark’s Décor Mark range represents a simple way for sign-makers to exploit what is proving to be a very rapidly expanding and attractive market for commercial décor; and, as many have already discovered, the materials also support the creation of functional décor elements used in wayfinding, branding, and other promotional applications.

A new vision

See-through graphics are also an ideal way to create visual impact for short-term campaigns, badging windows or glass doors with the latest promotion, product launch or event. And a new product from Contra Vision makes this option more cost effective and trouble-free for both client and printer.

The latest addition to the Contra Vision range of perforated window films, Contra Vision Campaign, has been developed specifically for shorter term campaigns, offering an economically priced perforated window film, whilst retaining the high-performance characteristics of Contra Vision. With durability for up to a year and clean and easy removal, the product is designed for external application. It is ideal for window posters and can be easily applied by staff, thereby removing installation cost—a benefit that will appeal to customers, especially in the retail sector.

Campaign, the latest addition to the Contra Vision range of perforated window films, has been developed specifically for shorter term campaigns. It is ideal for window posters and can be easily applied by staff, thereby eliminating installation cost

Technically, Contra Vision Campaign features a high specification clean-remove adhesive and the REACH-compliant face film construction, which ensures the best possible printing, application, and removal characteristics for this class of product. The material is available in 20, 30, 40, and 50 percent transparencies, which allows sign-makers to choose the image strength and see-through capability they prefer.

“The product is available with Contra Vision Grayliner, our patented improvement to perforated window films, which makes it easier than ever to produce outstanding see-through graphics,” comments Rob Stone, operations director at Contra Vision. He adds: “By matching the 70 percent monochromatic grey tone that is typically visible through the perforations on a window it provides the perfect background to view trial prints and assist print operators with colour matching and quality assurance during production and is suitable for all print technologies.”

Indeed, such has been the popularity and effectiveness of this new material range, that Contra Vision Campaign with Grayliner recently won a Product of the Year Award at the SGIA (the leading USA based, speciality printing and imaging technology association) in Las Vegas.

Direction of travel

Reviewing the current market, Derek Shedden, senior account manager at Innotech, a leading trade supplier of large-format printing materials, portable displays, and point-of-sale solutions, summarises the latest advancements in materials available for the sign and print industry from its portfolio.

O Factoid: Although many believe vinyl to be a relatively new creation, polyvinyl chloride (PVC) was in fact created in 1872 by German chemist Eugen Bauman. O

“Reflecting the drive and demand for a more sustainable future, recent years have witnessed the rise of textiles and PVC-free flexible substrates. These polyester materials are becoming increasingly popular amongst businesses across multiple sectors keen to reduce their carbon footprints. Leveraged for a widening range of applications, they’re particularly effective as stretch frame backlit light boxes in retail and exhibition environments,” Shedden notes.

This striking creation by Dominion Print, using Vertex Texture polyester fabric, demonstrates the dramatic and eye-catching effect that can be achieved with printed textiles

“Replacing traditional PVC materials, eco-friendly polyester materials are not just 100 percent recyclable, they’re also a greener option due to their light weight, making them more economical to transport,” continues Shedden, who adds: “This reduced roll weight—often as much as 60 percent when measured against PVC alternatives—delivers additional advantages to sign and print industry professionals, as it reduces the need for specialist handling equipment. Combine that with polyester’s increased tear resistance, and superior vibrancy of colour, and it becomes an even more attractive option.” Looking forward, Shedden believes we will see these trends developing further into 2017 and beyond, with flexible materials gradually phased out by a widening variety of textile products that are as strong and hardwearing as PVC banners.

With flexible materials gradually phased out by a widening variety of textile products that are as strong and hardwearing as PVC banners”

“While this process will take a number of years, it will be facilitated by the reduction in costs of environmentally-friendly materials as they become more commonplace,” he anticipates, adding: “We’ll also witness an increase in the popularity of wider reels, as 3.2 and 5m printers become cost effective options.

Myfotowall used Vertex Texture polyester fabric from Innotech to create wallpaper for this interior design project. Vertex Texture is a 300gsm fabric that can be pasted and applied to the wall, adding an extra dimension to the chosen image

“At Innotech, we’re always looking for ways to bring our customers the latest advancements. For example, we’ve just launched our new Envirotech PVC-Free material that conforms to government legislations for PVC-free specifications, even including demanding billboard applications,” concludes Shedden.

New horizons

Sign-makers are now frequently called upon to undertake refurbishment and re-surfacing projects on behalf of architects and interior designers. Whilst this falls outside the traditional scope of sign-making, their existing skills and experience, especially in the sphere of vehicle and other wraps, makes sign-makers the obvious choice to carry out such work, and, of course, opens up new business opportunities.

Within its portfolio of materials, William Smith offers a range of architectural products, which includes 3M’s Di-noc Architectural Finishes and Avery Dennison’s Facade range.

With professionals consistently having to work to a tight budget, these products are proving to be considerably cheaper when comparing refurbishment versus new-build projects.

Developed by 3M as a cost-effective design solution for interior and exterior new building or refurbishment projects, Di-noc Architectural Finishes offer a number of benefits, including ease of application, durability, and dirt resistance.

Providing over 900 patterns in a wide variety of shades, surface textures, and finishes, it also offers unlimited flexibility for the creation of natural or hi-tech effects for both modern and traditional environments. The wood, metal, marble, leather, stone, stucco, and many other finishes of this film can also be applied to walls, floors, furniture, and machines. It integrates well into both new design and refurbishment projects and is, therefore, suitable for a wide range of applications, including retail stores, hotels and offices, as well as for general interior design.

“Experience has demonstrated that in all market segments, refurbishment with 3M Di-noc self-adhesive films provides a budget friendly solution with high quality and excellent results,” says William Smith’s marketing manager, Lindsay Appleton.

“One of the main attractions for many busy businesses, such as offices, banks, bars, and restaurants, is that they can remain open during application of the self-adhesive films, as disruption in day-to-day activity is minimised, with no additional equipment or technology required,” adds Appleton.

When Signwright (UK) won a prestigious contract for Beverley Race Course, for refurbishment to the bar and other areas used by trainers and owners for corporate entertaining, they turned to William Smith for advice and support.

One of 3M’s Di-noc Architectural Finishes self-adhesive laminates was chosen by Signwright (UK) to create this impressive refurbishment to the executive bar area of Beverley Race Course

The brief required a finish that would complement the features of the overall project, providing a high-end look without a high-end cost, and to be completed within a twelve-week time span. On the recommendation of William Smith, 3M’s Di-Noc self-adhesive laminate film was selected for the project.

“Due to the thickness of the material, it required careful application,” comments Signwright managing director, Matthew Wright. He adds: “However, by working meticulously in accordance with 3M’s instructions, it applied very well and achieved the desired result. We also produced trial panels and put them to rigorous tests before starting full production.”

There were 27 separate elements to the project, the largest of which were the back wall panels. Wright continues: “In all around 500 panels were produced, all of which required precise and accurate finish to the corners, and nearly 2,000 fixings were used. We were working within a very tight time constraint but completed installation with around six hours to spare (and a few sleepless nights).”

Meanwhile, Avery Dennison’s Facade building wrap film offers fast, clean, and easy redecoration to a vast range of residential and commercial projects. Facade has been described as 'dry paint on a roll' and provides a cost-effective solution to restyle, refurbish, brand or decorate commercial, retail and residential buildings.

Avery’s Facade building film provides an easy solution to decorate buildings

“You can create a truly professional finish overnight, with minimum disruption to building owners, users and neighbours,” explains William Smith’s Appleton.

She adds: “Property owners benefit by saving on expensive repainting, as well as increasing the long-term value and improved building appearance.”

Designed for the demands of outdoor application and exposure, Facade film for building renovation offers UV and weather resistance, and comes with a ten-year warranty. It also offers conformability in one single layer, contouring smoothly around curved and irregular surfaces. With high adhesion on difficult building substrates such as plastics, aluminium, uncoated/coated steel, and reinforced facade panels, it offers a viable alternative to paint. It can even be applied wet for ease of application and has the flexibility to fit in any weather or temperature. Facade is available in a choice of 22 standard colours, or custom colour matching for RAL and Pantone colours.

As well as delivering a revitalised building, significant financial savings can be achieved of up to 25 percent over the economic life of the project, compared with conventional paint solutions”

“The impact is dramatic,” affirms Appleton, before adding: “As well as delivering a revitalised building, significant financial savings can be achieved of up to 25 percent over the economic life of the project, compared with conventional paint solutions.”

Bright and easy

Whilst discussing new and innovative materials for sign-making, we should not forget illuminated signage and display systems. For illuminated signage, Perspex Distribution’s Perspex G-lux is a newly developed cast acrylic sheet optimised with diffusion technology that allows sign-makers to produce edge illuminated light guide panels without the need to engrave or print the clear acrylic sheet, and offers a number of benefits for sign-makers looking to simplify fabrication of their illuminated displays.

Perspex G-lux clear acrylic sheet has been developed to be edge lit by LEDs, providing even illumination and maximising light output without the need for etching the sheet

“Developed to be edge lit by LEDs, G-lux panels offer an excellent light output and even illumination without the need for etching or engraving the sheet, thereby removing a further fabrication process and reducing workshop costs,” says Perspex Distribution’s marketing manager, Luke Martyn. He adds: “The built-in technology also works to produce the desired illuminated signage using thinner sheets and thereby slimmer lighting units.”

The built-in technology also works to produce the desired illuminated signage using thinner sheets and thereby slimmer lighting units”

The surface of Perspex G-Lux is a clear gloss, similar to Perspex Clear acrylic, and when illuminated offers optimum light output when used with a graphic or diffuser. It comes in four standard grades, each optimised to maximise light output at differing panel dimensions (extra small to large) and in thicknesses from 4mm to 8mm.

Indeed, Perspex G-Lux has been developed and manufactured at the Perspex acrylic factory in Lancashire and offers all the quality assurances of Perspex cast acrylic sheets, with a ten-year guarantee against yellowing, and 100 percent recyclability.

On the display front, in-store point-of-sale image systems that can be frequently changed are commonplace in today’s retail environment, not only for the ability to display eye-catching images, but for the ease of changing an advert or promotion product within minutes, giving a continuing fresh approach in store.

“Nova Aluminium’s Nova Tex system ticks all the boxes for such signage,” asserts Nova Aluminium director, Paul Vickery. He adds: “With four profiles to choose from, the designer has options for wall mounted and hanging units as well as free standing for single and double-sided applications.”

Nova Aluminium’s Nova Tex system comes in a choice of four profiles, with the option for wall mounting and hanging units

The Nova Tex system works by incorporating a silicone edge to the perimeter of the textile which, when pushed into the seating channel of the profile, causes the textile to tension itself automatically within the sign box or frame. A discreet pull tab is positioned in one corner, which allows the graphic to be simply pulled from its housing and replaced by another. Security screws can then be fitted to prevent unauthorized removal of the skin if required.

The Nova Tex suite of profiles consists of a single-sided box section with a depth of 83mm, a double-sided profile at 100mm, and two single-sided framing sections measuring 40 and 19mm.

Vickery explains further: “Manufacturing of the system could not be easier. The 19mm frame is fabricated using an internal chevron cleat system; and the 40mm frame and two box sections are assembled by use of a ‘fast fit’ corner angle facility, giving a perfect mitre joint every time. The two box sections can be illuminated with conventional LEDs and both frames can be back lit using LED light sheets.

Nova Display is again a textile display system but with a difference. The system has no need for a silicone edge to be employed on the skin itself, thereby eliminating any face preparation prior to printing. The skin is retained by using a gripper arrangement located within the face channel and the graphic is simply pushed into its seating groove with the tool provided.

The system’s ‘soft nose’ design gives an attractive edging to the visual and there are two profiles available. A single-sided box at 90mm depth and a double-sided box measuring 100mm. Both make use of internal corner fastenings and can be free standing, wall mounted or hung.

As I said at the outset, we can only create a snapshot of current developments in sign-making materials, but it is clear, even from this brief overview, that by keeping a keen eye on the ball and watching for new opportunities, there will be plenty of scope for sign-makers to diversify into new markets.

Your text here...