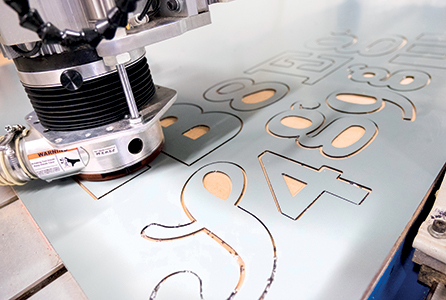

The larger-format AXYZ 4020 CNC router at William Smith’s new Smith manufacturing facility has led to 30 to 40 percent increase in output

Since their debut some 50 years ago, CNC routers have advanced

considerably, moving beyond their original environment in industrial

manufacturing. With the development of specific machines for the

sign-making sector, CNC routers have become a key piece of equipment for

many sign-making businesses of all sizes.

However, for those who currently outsource routing services, the

decision whether to bring routing in-house is a significant one. For

instance, will the return on investment justify the purchase cost of

such a piece of capital equipment? Can the machine be accommodated

within existing workshop space? And what are the benefits of bringing

the operation in-house?

Pros and cons

To gauge the pros and cons of bringing routing in-house, who better to

ask than some of the major manufacturers and suppliers of CNC routing

machines. Not only do they have the experience of providing the sign and

print industry with machines specific to its needs, they have also seen

the benefits that have been gained by their customers.

The latest Trident combined routing and cutting machine is designed to meet the requirements of the burgeoning print and cut sector, and offers sign-makers the opportunity to introduce a new revenue stream

Robert Marshall, vice president, market development, at AXYZ

International says the advantages are manifold: “They relate primarily

to the long-term savings in operating costs that will be achieved, plus

the elimination of variables on quality over which companies outsourcing

may not have complete control,” explains Marshall. He adds: “More

reliable turnaround on output to keep valued customers happy is also

more likely with companies that do not outsource their routing/cutting

requirements. These are considerations that might not be fully addressed

and implemented by a third-party supplier.”

He adds that with required materials becoming ever more costly, in-house

routing can help reduce or even eliminate scrap rates by getting the

routing/cutting process right the first time, thereby enabling huge

savings in production costs.

“Again, this is something over which companies that outsource routing

requirements would lose control,” Marshall continues, before explaining:

“Furthermore, there is no guarantee that the multiple different machine

configurations possible on customised routers (AXYZ router owners now

have a staggering 366,918 configurations from which to choose) would be available from a third-party supplier.”

Looking at potential disadvantages, he notes that, for the above

reasons, for high-volume users in particular, there are no visible

drawbacks.

“For very low-volume users of routing technology, however, there could

be short-term financial benefits of outsourcing by removing the need for

investment in capital equipment,” says Marshall.

In line with Marshall’s argument is the viewpoint of another key

manufacturer and supplier to the signage and graphics industry in this

sector, indeed Blackman and White has seen time and again that the

opportunities for their customers expand exponentially when they bring

digital finishing in-house.

Like Marshall, Blackman and White managing director, Alex White, sees

control as a key advantage: “Those opportunities come not just from

reducing production time by cutting out the need for subcontract

finishing, they also come from the increased level of control that an

in-house finishing facility offers. Having a complete in-house print and

finish solution offers the opportunity to take back quality control.

“It also helps sign-makers to experiment with which materials are best

suited for applications, perhaps even allowing them to suggest to their

client a different approach and actually taking a finished sample to

demonstrate their reasoning,” observes White.

It also helps sign-makers to experiment with which materials are best suited for applications”

Blackman and White’s Versa Tech is a versatile cutter with a multi-head

feature that has made it a popular choice for sign and print companies

requiring accuracy, reliability, and flexibility. The Versa Tech can

handle a range of substrates from self-adhesive vinyl, Foamex, Dibond,

Foamcore, acrylic, textiles, PVC, sandwich board, card, and paper,

making it particularly suitable for the sign and display market and

especially those companies who have made the move into digital textile

printing. It is available in flatbed, conveyorised, or laser-equipped

models for high functionality.

A new era

Complete CNC Solutions, the UK’s exclusive distributor for Italian

production routing hardware manufacturer, Protek, and major

international brand Tekcel, has also helped many businesses transition

into manufacturing their own routed output. Its focus has been squarely

on choosing to distribute equipment that puts a premium on the quality

of its finished output straight off the bed.

According to Complete CNC Solutions’ managing director, Julian Sage, the

question of whether to install a routing capability and bring

production in-house is today easier to answer thanks to the availability

of equipment such as the new Protek system known as the Unico TT. The

system is also a fully featured production scale digital cutter that

Complete CNC Solutions claims is capable of outperforming dedicated

flatbed print finishing systems.

“Having a serious production router and fully featured digital cutter in

one and the same system delivers an element of capability not found in

any other routing hardware,” stresses Sage, who continues: “As a result,

production class routing is there for the taking when it’s needed and

the machine’s time and available capacity is better utilised thanks to

the other things it can do.”

Sage adds that exemplary results are possible with very little manual

intervention using the Protek Unico TT, which is said to produce routed

results that require no further manual finishing.

The Protek Unico TT from Complete CNC Solutions offers production routing and print finishing in one and the same system

“That’s a huge benefit to someone bringing routing under their own roof.

Finishing marginal quality output takes a lot of expensive labour and

time,” comments Sage, adding: “Having a machine that removes the need

doesn’t just save time and money, it makes the whole question of

satisfying your own needs for production routed output much easier to

consider.”

Further extolling the virtues of the Protek Unico TT, Sage affirms:

“It’s a ground-breaking product capable of taking businesses forward.

It’s a system capable of assuming the role of a primary production

routing device and yet versatile enough to carry a business beyond

simple routed output. Its capabilities can be explored and exploited on a

phased basis and its depth is such that a business with one in the

workshop will be able to say yes to any job that comes its way.”

Seat at the table

It is an old adage that ‘the proof of the pudding is in the eating’, so

what is the perspective of those ‘at the dinner table’—sign-makers who

are currently offering an in-house routing service?

William Smith, a leading trade-only supplier to the sign industry, is a

firm advocate of in-house routing. In conjunction with the launch of the

Smith brand as its manufacturing arm, the company has recently

installed a second and larger-format AXYZ CNC 4000 series router to

support its existing AXYZ model.

AXYZ’s CNC?4000 router, shown here profiling cut-out aluminium letters has enabled Smith to achieve better engagement with higher volumes of large contract work

Production manager at Smith, Martin Rodgers, comments: “Installation of

the larger-format AXYZ 4020 CNC router has led to a 30 to 40 per cent

increase in output as well as a huge reduction in production time and

thus greater profitability. It has also enabled better engagement with

and higher volumes of large contract work and in particular that for

major corporate ID signage projects.”

Another good example of successful installations in this field is

Practical Minds, the Nottingham-based specialist in project management,

retail design, manufacture, print and installation, which opted to

invest in a Versa Tech cutter from Blackman and White to add value to

their offer for clients throughout the UK and EMEA.

The Versa Tech, with a 3,000 x 2,000mm cutting bed, was installed in

February 2016 and is allowing the company to complete cutting and

finishing processes for their print and plastics division that

previously had to be carried out by external suppliers.

Managing director Andy Winstanley says: “The Versa Tech has added

another string to our bow, as well as helping us offer a quicker

turnaround when working with materials such as card, acrylic, MDF,

vinyl, foamex and Dibond. Having the cutter in-house allows us to

guarantee the quality of finishing that our customers expect, within the

timescales they demand.”

Winstanley formed the company in 2008 and has seen it flourish and

increase its team from three to more than 25 by ensuring they deliver

excellent quality and service on all projects—something that has been

greatly improved by bringing the finishing in-house.

“We looked at other manufacturers but decided on the Blackman and White

Versa Tech because we were so impressed by both the machine and the team

behind it,” he continues, adding: “Having easy access to servicing and

support direct from a British manufacturer is fantastic, and our

experience with the Versa Tech so far has been great.

“The quality of installation was excellent and we even ran real jobs

during training, including the successful production of inlaid and

curved laminates, used for a major tourist attraction on behalf of

Merlin Entertainments. The machine proved itself straight away and it

was worth making the investment in a bigger machine,” concludes

Winstanley enthusiastically.

A word to the wise

Even with its myriad of benefits, bringing routing in-house is clearly

not a decision to be taken lightly. Our manufacturers and suppliers

offer some words of wisdom.

AXYZ’s Marshall starts the ball rolling: “A prerequisite would be to

make sure that the routers to be installed can meet the precise

requirements of the work to be undertaken. Furthermore, the machines

should be fully configurable and capable of accommodating all future

upgrades. Special attention should also be made to the choice of

routing/cutting tools and the software employed, as both are critical to

the router’s performance.”

Starting from a very practical point of view, White advises anyone

considering an investment in a router to make sure they understand the

necessary factory floor space that will be required, not just for the

machine but also the parts in production and making ready for despatch:

“Understanding your products and your market aspirations is also

important in deciding on the right cutting machine. As a supplier with a

range of products including our custom Orion, Genesis and Master Cut as

well as the Versa Tech range, Blackman and White understands it’s

important we discuss each customer’s individual needs before

recommending a machine.”

Time, experience, training, and back-up are also important factors, as

White emphasises: “A certain level of experience is needed to cost

effectively manufacture finished parts without making expensive

mistakes, wasting materials and cutting/routing parts. However, by

working with technical teams such as ours, discussing your precise needs

and by putting aside the right amount of time for training, an

investment in in-house routing can be a real door opener for new and

expanded business opportunities.”

O Factoid: The first handheld power routers were invented in 1915 and were jet motor hand routers, called Onsruters. O

Taking everything into consideration, it seems that there is everything

to play for and very few, if any, disadvantages to bringing routing

in-house, provided you research and plan carefully and look to reliable

suppliers for advice and guidance. What is more, it can open up a whole

new range of business opportunities.

Carve your way to profits

A key element of any investment into CNC routing and cutting equipment is the CAD/CAM design software you run in conjunction with it, which could really could make or break your return on investment.

Vectric is a UK-based software developer in this sphere that has established an impressive reputation for itself and boasts a very large international user-group.

One of its flagship systems is V Carve, which provides an intuitive software solution for cutting 2D design and calculation of 2D and 2.5D toolpaths—along with the ability to import and toolpath a single 3D model. There is also support to import multiple Vectric Clip Art 3D models (V3M) to create advanced 3D assemblies.

V Carve Pro is designed for ease of use but complex capabilities

A good example of an international V Carve Pro user is Claudio Pontes, which went from hobbyist to full-blown sign-maker through the use of this technology: “I bought VCarve Pro a little over a year ago and since then I have been learning how to program with it. The ability to preview the result is a very strong point of the software. The excellent video tutorials and the affordable price of the software were the main reasons for choosing VCarve Pro.”

Although Pontes programs V Carve Pro and operates the CNC router, it is his wife Marisônia Pontes, with an aptitude for fine arts, who gives the final touch to the parts by applying the stain or paint. Literally creating a perfect marriage of skills.

Your text here...

Your text here...