Sign-makers who move to invest in a wide-format flatbed printer, such as the Mimaki JFX200-2513, will find a whole new world of applications and business opportunities open to them

In case you are somehow not aware of it already, Sign and Digital UK is finally upon us. Sign-makers and print-service-providers across the land are flocking to the bright lights of Birmingham’s NEC to check out the best and latest in sign-making and printing technology, from intricate bevellers to enormous flatbed routers. Wide-format printers are also going to be a huge presence at the show (literally), and what with the vast market opportunities made available by an investment, this might be the ideal opportunity for teetering sign-makers to take the first step into the ‘world of wide’.

Even after making the decision to buy, however, it is not always easy to find the right machine for your business. For sign-makers looking to expand into markets such as outdoor graphics (building and vehicle wraps, to banners, and billboards), indoor graphics (floor and window graphics, backdrops, and promotional or exhibition graphics), or looking into applications on a wide range of substrates, a wide-format flatbed is the obvious option.

Luckily, flatbed manufacturers are aware that first time buyers are usually looking to expand, but do not want to make an enormous investment which could end up gathering dust in the corner.

About the current state of the market, Dominic Fahy, business group manager, display graphics systems and imaging supplies at Canon UK, says: “We’re seeing a lot of enquiries from sign-makers, digital printers and screen-printers, and other organisations looking to enter the market. We are seeing a lot of people, particularly sign companies, upgrading from roll-fed solvent-based systems. Their volumes have grown, they are looking to be more automated, and they want to provide a wider range of applications. They are looking to invest in a flatbed system.”

Wide-format flatbeds do not come cheap however, and Fahy has noticed that the higher the cost the more pressure there is to choose the right machine.

In terms of cost of wide-format flatbeds, continues Fahy: “Even the entry-level can be quite a stretch and come in as a significant investment for a business. When they bought their first machine, it probably cost around £20,000 whereas a flatbed will be getting on for three times that. It’s quite a big purchase.

An entry-level machine is a business investment that has to work because it is significant to these companies and they have to get it right first time”

“What we find when we are talking to sign-makers interested in getting into flatbed printing is that an entry-level machine is a business investment that has to work because it is significant to these companies and they have to get it right first time. They don’t have the opportunity to invest in technology that doesn’t work. They need to make sure that what they’re buying is proven to be a good machine in the UK market and they have to know that the manufacturer or company has the capability to support them well.

“Also for a lot of people getting into the flatbed market for the first time it will all be new to them,” Fahy continues, adding: “There’s a lot to learn about how to use the systems, about the environment they need to be kept in, to get the most out of the machine. We spend a lot of time working with our customers on all different applications they want to print. Suddenly they go from having very specific media that they print on, to being able to print on anything.

“So we make sure we have a lot of conversations about ‘how to’. We don’t just hand the printer over. We also like to make ourselves available to the customer to advise them on what material to use, and how to use it, basically sharing that information with the customer.” Canon’s entry level flatbed is the Océ Arizona 318 GL, which takes a rigid media size of 4 x 8´ (1.2 x 2.5m) and media thickness of up to 1.89" (4.8cm). Canon quotes production speed it 40sq m/h, but quality print speed at 27sq m/h, an important distinction to make when viewing quoted production rates.

Canon’s Océ Arizona takes a rigid media size of 4 x 8’ and media thickness of up to 1.89"

Fahy sees the Arizona as a perfect entry-level option for several reasons. He says: “Our system is particularly well suited to entry level because it also has a roll media option on it, so you can print to flexible media or roll-based media, as well as onto flatbed. This provides flexibility and makes it a very good all-rounder, so that one machine can do an awful lot of different applications, which, in our experience, is what people are looking for when they first look into wide-format.”

The Arizona has a fixed bed, rather than a moveable bed, which Fahy sees as the preferable option, saying: “With our machine, the media is held in place by a vacuum. That enables you to get a lot of creative effects like adding white ink, or double layers of colour. When you keep the media still the machine is much more capable of ensuring that the quality across that whole side of the substrate is the same. Also when you print it twice, the ink is always going in the same position. When it’s moving through the system you have to reposition it. There are certain limitations with a moving bed that you don’t have with a flatbed, which is one of the big benefits in the way that our system is designed.”

Fahy goes on to explain how entry-level machines must be flexible, but keep exceptionally high quality. He says: “There’s no compromise on quality with our entry level machines. The image quality on these systems is the same as on the bigger ones we sell. It’s not a question of whether there is any compromise, it is simply at a lower production level.”

Aim for the stars

Rob Goleniowski, sales support manager at Roland DG UK agrees that high quality and flexibility are the most attractive qualities about the wide-format flatbed, and this is proven in the way sign-makers up and down the country are still making the choice to move into the market.

He says: “In our experience, this market at the moment is very buoyant. A flatbed machine is quite an aspirational product for sign-makers, so this combined with the growing range of applications that can be produced using these machines is keeping the market buzzing and sign-makers interested.

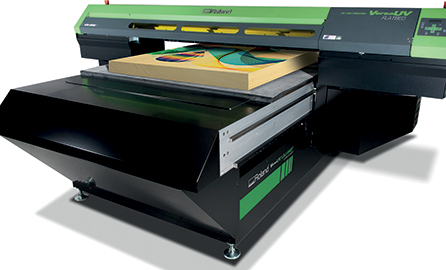

“The growing number of entry-level flatbed and hybrid UV printers like our own VersaUV LEJ-640F and LEJ-640 are breaking down the barriers to entering the flatbed market, offering sign-makers and printers an opportunity to confidently and cost-effectively enter this market.”

Reliability and versatility are the keys to maximising a wide-format machine’s return on investment”

From his conversations with sign-makers, Goleniowski has noted a few things first time buyers should be looking for in this large investment. He says: “Reliability and versatility are the keys to maximising a wide-format machine’s return on investment. Flatbed machines are a much larger in-vestment than sign-makers are generally used to, so the business case needs to be clear and robust.

The VersaUV LEJ-640 from Roland is a top of the range versatile hybrid printer, accepting both roll and rigid media substrates, from thin films to lightweight board and cardboard up to 64” wide

“Sign-makers should work closely with their providers to understand how durable the inks are too—it’s one thing to print on a range of substrates, quite another for that print to then last and meet the expectations of the client in terms of quality and longevity.”

He advises thorough research before purchase: “Take the time to understand the level of versatility these machines offer, the substrates they can print on, and what this potentially offers your business in terms of new revenue streams and market sectors. The greater the understanding, the more potential you have to maximise your return on investment.”

In terms of versatility, Roland’s entry-level VersaUV LEJ-640 is a strong player. The printer is a hybrid, accepting both roll and rigid media substrates, from thin films to light-weight board and cardboard up to 64? wide. Goleniowski continues: “With its ability to print on a vast array of substrates including 8 x 4´ (1.2 x 2.4m) board stocks up to 1/2? (13mm) thick, the LEJ-640 is perfect for wide-format signage and point of sale displays, window graphics, exhibition displays, packaging prototypes, and interior décor items.”

Roland also offers a dedicated flatbed in the shape of the LEJ-640F, which has an extendable table of 1.625 x 2.1m (5´3? x 6´ 10?) and can print on substrates up to 15cm (5?) thick. Goleniowski says that the machine is: “Capable of printing CMYK plus white and gloss inks onto both rigid and flexible substrates up to 6? (15cm) height, the LEJ-640F truly outperforms traditional CMYK-only machines. It offers printers and sign-makers the real flexibility needed to produce the broadest range of creative, high quality, and profitable applications, including POS displays, packaging prototypes, outdoor and indoor signage.”

The Roland VersaUV LEJ-640F has an extendable table of 1.625 x 2.1m (5’3’’ x 6’ 10’’) and can print on substrates up to 15cm (5’’) thick

Game-changing technology

Wide-format reseller and Mimaki distributor Hybrid Services is another good place to start when searching for the next big investment.

Stuart Cole, Hybrid’s industrial products sales manager, says the market for wide-format flatbeds is in a good position at the moment, saying: “After a decline in some mainstream technologies, there has been a sharp increase as game-changing new products have come to market giving print providers excellent quality and capabilities, but at an entry-level price point.”

O Factoid: The official definition of a ‘wide-format’ (or large format) printer is that it supports a maximum print roll width of between 18 and 125" (0.4 to 3.2m). Printers over 125? wide are considered super-wide- or grand-format. O

In terms of what to look for in a flatbed, Cole weighs in with his advice, saying: “Firstly, print quality is very important, as is a good colour gamut. The inks are equally something to be considered; good adhesion is essential and considering how well they perform after finishing.

“The ability to print 8´ x 4´ (2.3 x 1.2m) sheets as a minimum and a print head that accommodates a 2? (6cm) thickness open up great potential. Using LED-UV lamps is a must, not just for the green credentials, but for the financial benefits too, such as low running costs, significantly extended lamp life etc.

“Finally, a sign-maker should consider ease of use—if the printer is easy to work then it frees up time of ope-rating staff, increasing productivity.”

Mimaki’s offering, the JFX200-2513, says Cole is considered ‘entry-level’ because of its lower price tag. However, he continues: “Its technological capabilities far exceed that of its more expensive competitors which is why it’s such a popular choice.

The Mimaki JFX200-2513, available from Hybrid Services, uses LED-UV curing technologies offering ultra-low power consumption and a range of environmental benefits

“The Mimaki JFX200-2513 maximizes productivity by using industry standard media on its 2.5 x 1.3m (8´ x 4´) bed and delivers vivid images even on transparent media through use of white ink. The JFX200 also makes use of innovative LED-UV curing technologies, offering ultra-low power consumption, the ability to print on to heat sensitive media, and Instant on/off lamp switching.”

When money is an issue, running costs are all important, which makes the LED-UV flatbed a particularly attractive option, with its long life curing unit and low heat output. Cole also stresses the environmental benefits of the new technology: “Hybrid has made a big commitment to educating the market on the benefits of LED-UV and the Mimaki JFX200-2513 has all the environmental credentials associated with this. As people learn the advantages of LED-UV technology, they will have even more reason to move to investing in a wide-format flatbed.”

See for yourself

There are obviously many more manufacturers out there catering for the sign-maker moving into wide-format flatbed production. For example, Korean manufacturer Inktec has the Jetrix KX3 (1.2 x 1.2m), KX5 (2.5 x 1.3m, KX7 (2.4 x 3m, and KX7D (with double the number of printheads), which range in print speeds from 26 up to 60sq m/hr. Durst on the other hand has an entry-level model—the Omega—which is a hybrid printer with a 5´2? (1.6m) print width, a resolution of 1728 dpi, and a production speed of 35sq m/h. There is also a choice between the conventional UV Omega 1 and Omega 2, identical except it uses LED-UV curing technology. EFI launched the H1625 LED hybrid at FESPA 2014, which is also designed for the entry-level user. The 5´2?(1.6m) wide printer can print up to 42sq m/h, has CMYK ink and two white channels, whereas HP’s equally wide Scitex FB500 and FB700 hybrids with belt drive media transport systems, can produce up to 37sq m/hr at 1200 x 600 dpi.

All manufacturers, save Durst and EFI, are exhibiting at Sign and Digital UK 2015, so the best way to find the best entry-level wide-format flatbed is to go and see them for yourself. Canon’s Fahy sees the show as the ideal place for first time buyers and encourages visitors to see him at their stand (G10). He says: “It’s a really important show for companies that are looking at entry level systems. We talk to a lot of people who are buying their first flatbed at Sign and Digital UK so it’s a very important show for us, something we’ve been at for many years. We really value all the conversations we have with people at that show. There are a lot of sign-makers looking for their first flatbed there.”

Goleniowski says Roland’s flatbeds will be centre stage on its stands (F34, G30): “We’ll be inviting customers and all those attending Sign and Digital UK to come and see the amazing quality and extraordinary range of high quality, highly profitable applications that can be produced on the LEJ-640F, the LEJ-640 hybrid printer and the LEF-20 desktop device.”

Cole says Hybrid services is attending Sign and Digital UK (stand D10) where it will be demonstrating the full Mimaki range, including the Mimaki JFX200-2513. He says: “Running the JFX200 at the show will give visitors the opportunity to see close-up the high speeds on offer coupled with ‘live’ print samples to demonstrate the superb quality that can be achieved. Visitors can watch the Mimaki JFX200 being operated to understand how easy it is to use and how useful its 8´ x 4´ print bed is to professional sign and graphics companies printing rigid boards.”

The team from Spiral Colour with InkTec’s Ben Woodruff

Indeed, a good example of just what an impact such technology can have on a business in our industry comes from Spiral Colour, a customer of the aforementioned InkTec that bought a Jetrix 3015 UV flatbed through Mayday Graphics. With European Digital Press award under its best, the machine can print to glass, wood, and stainless steel among a range of difficult substrates due to the built-in varnish and primer function within the printer.

Jason Carpenter, production manager of the firm commented on the investment after it had bedded in: ‘‘After having the machine running solidly for four months, I can honestly say that it is the best piece of equipment that we have invested in so far. Our revenue and profitability are up and the amount of hours I need to spend here are down.”

InkTec’s UK sales manager, Ben Woodruff adds: “When I first met Jason and Jamie it was immediately apparent that they were an ambitious company and had big plans for the future.

The JFX200-2513 demonstration at Sign and Digital 2014: All the companies agree that Sign and Digital UK is a great place to see the wide-format flatbeds working in real time, giving sign-makers all the information first hand

“They were also very conscious of their current production time and overheads, which included a fair amount of wasted media each month. Because of the low running and maintenance costs, this was an area that the Jetrix was able to offer them a significant saving. Their wastage will drop as they can now print direct to substrate and edge-to-edge for a far more efficient production process. Couple this with the additional capabilities the Jetrix will bring, like white ink, varnish and primer, they have certainly future-proofed themselves.”

Carpenter added: “To highlight the amount of material we have saved, you only have to look our bins each month. Before we had at least three full up with wasted media and now this is less than one. This saving alone is covering a large proportion of the monthly Jetrix repayment.’’

So, with such a range of wide-format flatbeds on the market, now could very well be a good time to take the step into the wide-format market, and see what a world of new signage and graphics applications and opportunities open up.

Your text here...