One of the industry’s top performing machines, Graphtec’s FC8600-160 is built for industrial standards of use and can cut at 1485mm/s with a cutting force of 600g. A key feature is its Fast Landing technology, which increases its acceleration to full speed

There have been some pivotal moments of technology innovation that have shaped the sign industry over hundreds of years. But perhaps one of the most pivotal was the introduction of the world’s first automated vinyl cutter in the form of the Signmaker (Graphix) III from Gerber Scientific Products, which was publicly introduced to the market November 1982—it featured a four character display, could take eight fonts, and process one line of text. Nevertheless it was a technological revolution and meant you did not need the skills of an artisan to produce sign lettering.

With Gerber continuing the development of its systems, the scene was set for a flurry of innovation, intense research, and development. Running on a pre-DOS system called CPM, next on the scene was the first-ever computer driven cutter plotter in the form of Grafityp’s Computerised Sign-making Robot (CSR) in 1984.

One of the next big releases came a few years later in 1987 when Mimaki launched its affordable MF-220C and CF-70 cutters, closely followed by its CG-45, and 60/90 models in 1988. In the same year Roland DG unveiled the CAMM-1, the world’s first dual pu-rpose vinyl cutter and pen plotter.

A big time for the market, late 1988 also saw Graphtec launch the FC2100-90, with Summa following up with the T1000 in 1992. Reacting to market demand and growing competition, Roland DG then launched its low-cost Roland DG CAMM 1 PNC-900 up-grade in 1993.

The rest is history and has seen these main players continuing to trade technology blows right up to the modern day. But a key threat to sales has been an influx of cheaply manufactured technology that can be bought over the internet.

Often the purchasing decisions of a start-up, or indeed established business, is driven unwisely by immediate budget”

“Often the purchasing decisions of a start-up, or indeed established business, is driven unwisely by immediate budget with little concern over the business implications of longevity or reliability of the machine, or the after-sale support,” counsels Mark Elvidge, print product manager, Roland DG (UK).

He continues: “Roland’s CAMM-1 cutter, launched in 1988, made vinyl cutting easy and affordable and, along with its competitors of the day, transformed the industry. Investing in capital equipment for any business, especially a start-up, is always a considered choice. With a fixed budget and a long list of equipment to buy, it can be tempting to opt for cheaper options, possibly sourced from the internet. However, not all cutters are created equal and investing a little more up-front will pay dividends in terms of reliability and performance, right from day one.”

The right questions

Elvidge is keen to emphasise that an investment in a vinyl cutter also needs to be framed by some fundamental consideration: “Sign-makers need to consider who will advise them on how to install their plotter and configure it so that it can get to work and start paying for itself straight away. It should also come with easy to use, powerful software with specific functions tailored to cutting.

“The software also needs to include plug-ins that will enable it to go off industry-standard packages such as CorelDRAW and Adobe Illustrator. Further considerations also need to focus on whether the machine will be reliable and supported by a warranty directly from the manufacturer. And if the machine requires technical support, will you be able to call upon a team which is backed up by experienced industry specialists, many of whom have used these products in production environments for many years?”

Both Elvidge and his industry contemporaries all seem to be singing off the same hymn sheet, encapsulated by the idea that investing in a reliable, well-built product that offers solid technical support and training will repay a business with top-quality output and concrete predictability.

Roland’s CAMM-1 Servo GX-24 professional cutter kicks off its offering and features digital servo-motors to achieve maximum accuracy, a curve-smoothing function to allow precise cutting and automatic cropmark detection for print and cut applications. The GX-24 also comes with Roland Cutstudio software which lets users enlarge, reduce, re-position, rotate and mirror graphics. It also includes CorelDRAW and Adobe Illustrator plug-ins.

Packaged Roland DG’s key software systems, the CAMM-1 Pro GX-640 can cut up to 850mm/s. The company ran a competition a few years ago to find the oldest CAMM-1 still in service, with the winning customer running his machine for 17 years

With the same bells and whistles while moving up the range, Roland’s CAMM-1 PRO GX-300/500/640 Series offers increased size, speed and pressure with the ability to cut at 850mm per second and with 350gms of pressure. It also offers CorelDRAW and Adobe Illustrator plug-ins and the machines are compatible with Roland’s powerful VersaWorks RIP software to allow the user to contour cut finished prints. At the top of the spectrum is the 64-inch GX-640, which is ideal for the largest jobs and heaviest materials. It features Roland’s most powerful servomotor and includes a ‘heavy mode’ function for handling the very thickest media including sandblast media and reflective materials.

Making the cut

While some of the original players in this field diversified into wide-format inkjet printing, those such as Graphtec and Summa specialised in developing dedicated cutters and deepening the breadth of their technology in this area. The latter’s latest offering was on show most recently at FESPA 2014 and sees its S Class 2 T, D, and SummCut Series providing a very comprehensive offering. The company has also concentrated heavily on the development of its flagship ‘OPOS-CAM’ technology to further enhance the accuracy and speed of its systems.

Phil Kneale, director of Graphtec GB, explains that there are now some key trends shaping this core technology sector: “Every sign-maker has cutting technology, but a big change has been the intense diversification that has been going on in most businesses. For example, they are now into using flock and flex materials for print-wear products and just trying to squeeze every last penny of potential from their technology.”

Grafityp GB has an extensive range of vinyl cutting systems from both GCC (Pictured at Sign and Digital UK 2014) and Roland DG. It was one of the very first entrants to the sector with its Computerised Sign-making Robot (CSR) in 1984

Graphtec GB’s head man is keen to explain that most start-up sign-makers seem to follow the same path in that they tend to buy technology on a very tight budget before improving it as their business scales up. But this is something of a false economy says Kneale, explaining that the company will grow more quickly and ultimately spend less money in its first few years out by just buying right first time.

“The first key area of consideration with a budget buy is wasted material,” says Kneale, adding: “One of the big problems with a cheap cutter is that the material will not run perfectly straight due to the poor tracking systems. If you are only doing small stuff then you will probably get away with it, but anything around the 2m mark and it will cause issues almost every time.”

Summa’s marketing and communications manager, Daphne Mertens, was on hand at FESPA 2014 to provide a sneak peak at the company’s latest flagship cutting systems

Kneale continues: “The second more obvious problem is durability with cheaply manufactured machines, which is especially true of the Chinese manufactured systems. With every day trade use they will normally last less than 12 months, and if they haven’t actually caught on fire by then they will break down.

“This means in your first few years in business you will end up buying two or three machines. Now because you are only paying £600 or so for your cutter to start with it doesn’t seem so bad, but after all that time you will have spent more than the cost of a high-quality option, while still being left with technology you know is going to fail you. So, instead of spending around £1,200 at the start, by year three you could have spent more than £1,800 and who knows how much more lost mar-gin in material waste before you finally decide to buy a better quality machine.”

End-to-end thinking

Another key consideration is the unforeseen damage that a machine’s failure at the wrong time could cause your business. A good example is securing that first big client, with that inevitable tight deadline. If you can rely on your technology to do the job first time then all will be well. But if it breaks down or you become snarled up in re-running graphics due to registration issues, then missing that deadline could cost you the client and a lot of lost revenue.

“With any of the professional cutters, you load your material, walk away and they do the job. More often than not with cheap alternatives you will be hunched over it nursing every last inch through the machine,” says Kneale.

The time spent weeding graphics also needs to be considered, as the accuracy of the latest models from the major players means no hassle painstakingly trying to unpick poorly cut vinyl from its backing using a scalpel.

“Weeding is perhaps the most labour intensive thing that the sign-maker will have to do. And especially for bread and butter work like menu boards, it can make a huge difference to the productivity of a small business if the graphics just weed cleanly and quickly every time,” continues Kneale.

Looking at the nuts and bolts of Graphtec’s offering, it is broken into two ranges. The C series which runs up to 1,000mm/s with a cutting force of 500g and the more industrial strength FC series. This latter class runs at 1,445mm/s with a cutting force of 600g, has a heavier chassis, and is designed to cope with bigger roles of materials—its sizes run through five gradients from 60 to 160cm.

Graphtec’s CE6000-60 runs at 900mm/s with a cutting force of 500g and the same cutting quality as its big brother the FC—the series runs at a top speed of 1,000mm/s

With both ranges providing the same quality of cut, the C series has three size options of 40, 60, and 120cm and has all the major modern features you would expect, such as advanced registration mark sensors. However, it lacks some of the refined features of the FC series, such as ‘Fast Landing’ technology. This essentially allows for quicker automated set-up and cutting time without a loss in quality. Kneale advises that those sign-makers going through more than a role of vinyl a day should be looking at the heavier models, but if you are cutting around 10m a day then the C series would be the better option.

Spending a little bit more up front will actually save you a lot of money and hassle down the line”

Kneale concludes: “Graphtec is a dedicated cutting plotter manufacturer and we have got it down to a fine art. Simply put, we are good at what we do. A key stumbling block for many is often price, but going back to my previous comments then it should be clear why spending a little bit more up front will actually save you a lot of money and hassle down the line.”

Speaking to Kneale, another key offering that helps the company stand out, a featured mirrored by a number of his key contemporaries, is that Graphtec GB has a dedicated technical support line, qualified in-house engineers, and next day call-outs. He also advises that if a machines’ warranty is still in place then a replacement machine will be supplied if it cannot be fixed on site.

Competitive market

One of the biggest names in sign supply in the UK is Spandex. In addition to supplying Gerber’s GS and Envision series of cutters as well as Summa’s range, it also stocks the most recent entrant to the market in the form of Mutoh with its Kona cutters—launched in 2009. This puts Spandex in the enviable position of being the torch bearer for the technology that kicked of the entire market. Grafityp is another historic player which has remained in the sector and set up its UK wing in Tamworth some 23 years ago. In addition to now being a reseller for technology from the afore-mentioned Roland DG, it also supplies Taiwanese-headquartered GCC’s technology.

O Factoid: The first ever automated cutting plotter, the signmaker (Graphix) III was launched on November 1982 by Gerber Scientific Products. Costing more than £6,000 (£15,000 today) and with each font coming in at £250 (£600 today) it featured a four character display, could take eight fonts, and process one line of text at a time. O

Grafityp’s range scales up from its GCC Puma series (600mm/s, 400g cutting force, 590 to 1300mm cutting widths), to its Jaguar Series (1530mm/s, 600g cutting force, 610 to 1830mm cutting widths ), and its new RX series of cutters. While this has the same base stats as its Jaguar cousin, it can accelerate to speed more quickly, has a much bigger memory (16 instead of 4GB), and also features Grafityp’s Automatic-Aligning System (AAS II) for higher accuracy during industrial production.

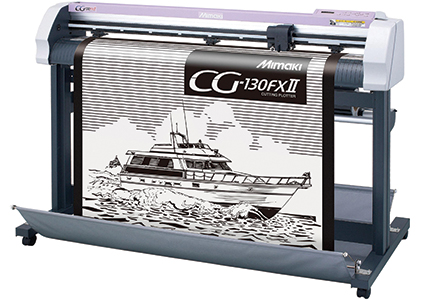

Another key player that has diversified its offering more than any other original market player is Mimaki, which has technology that spans the spectrum of wide-format inkjet as well as print and cut. The company also has a range of dedicated cutters in the form of its CG brand, which has a com-parable brand and width architecture to its key competitors. With speeds running from 500 to 1,000mm/s, the range goes from its desktop 60 series, through its SRII and SRIII systems, to its high-performance FXII series. Excepting the desktop systems, each features a two year warranty and comes with Mimaki’s FineCut plug-in soft-ware.

Mimaki’s CG-130 FXII is the company’s flagship cutting technology and runs at 1,000mm/sec with a cutting force of 400g. The technology has a two-year warranty and comes packaged with a range of advanced software solutions to ensure production efficiency and cutting accuracy on big projects

Able to offer customers a choice between purchasing a stand along dedicated cutter in combination with a wide-format printer or a print and cut device, the national sales manager of the company’s exclusive UK and Ireland distributor, Hybrid Services, weighs in on the markets trajectory.

“Vinyl cutters are going to be around for a long time to come and it is a core tool for the sign-maker,” says John de la Roche, who adds: “We have been there from the start of the mass market for these devices some 26 years ago, and the sector is still huge. If you look at everything from the thousands of liveried vans on the road through to the shell schemes at exhibitions across the country, it’s all cut vinyl.”

A cut above

De la Roche continues, echoing the sentiments of Graphtec’s Kneale: “As the technology has come down in relative price and matured, competition from manufacturers in areas such as China has affected the market. But there is a reason that people are still using cutters from the main manufacturers they bought ten years ago or more; it’s the build quality and ongoing support.

“I have heard countless sob stories from customers who have come to us after being burnt with buying technology from internet stores. These machines perform for a short time, but when they go wrong and you need support, who are you going to call? Ghost Busters?”

Looking at the detail of the build difference between budget machines with no UK support and those of the main players, it is not one individual major component that results in a quality cut throughout a run. Rather it is all the hundreds of interdependent systems working in harmony with the software to make sure that your standard 18 micron vinyl is cut to the exact right depth, across an entire run, day after day. What is remarkable is that after 32 years every major player there at the foundation of the vinyl cutting sector is not only in existence, but still thriving. For those still suffering under the yoke of underperforming technology, perhaps it is worth considering this fact and investing in technology that is a cut above the rest.

Your text here...