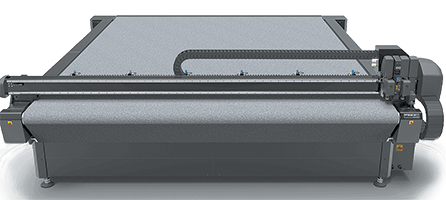

Flatbed vinyl cutters do as the name suggests, and vinyl can be used for anything from car wrapping to sign letters

Flat out for vinyl

Flatbed vinyl cutters are a crucial tool in a sign-maker’s arsenal, especially if that sign-maker works with vehicle wrapping or even sign letters. Whilst it may not be in constant use like other machines, it is still an important piece of equipment.

Kirsty Reader, general manager of Granthams, which supplies flatbed vinyl cutters to customers, says that investing in one is becoming an increasingly popular choice. Granthams supplies ranges from Graphtec GB and Summa. Reader explains: “In most sign-makers’ workshops, you can guarantee that there will be a CAD vinyl cutter sat waiting patiently or chattering away at full capacity.

O Factoid: Car wraps can cost as little as 4p per thousand impressions, making vinyl a valuable marketing tool (The Sussex Sign Company). O

“Designed to hold a roll of plotter vinyl, they are the go-to solution for vehicle graphics, sign letters and plot-cut self-adhesive shapes. But what follows on from these roll-fed machines? What if you need something more substantial to cut both vinyl media and maybe even rigid substrates? This is where a flatbed vinyl cutter is becoming an increasingly popular and effective investment.”

Car wrapping is just one use for vinyl

What is it?

But what is the difference between a conventional cutting tool and a flatbed cutter specifically for vinyl? Reader explains: “As the name suggests, the flatbed is designed to take a sheet or panel instead of a roll of media. The sheet is placed on top of the bed and a vacuum keeps it stable and in place, ready to be cut.

“The cutter’s software selects the trim path and, by utilising the correct tool for the intended end purpose, the machine moves its way around the registration marks working away at the task in hand.”

Of course, with any investment, particularly in this excruciating political turmoil and uncertainty, sign-makers will want to weigh up the benefits of spending money versus outsourcing any projects. Then there is also the argument of cutting by hand using a bench cutter. Reader says that there are a number of benefits when investing, including accuracy and increasing productivity.

A flatbed vinyl cutter could be a wise investment to avoid manual cutting

She continues: “The main benefit of the flatbed cutter is in its unparalleled precision. The substrate being trimmed never moves – the vacuum holds it securely in place. Only the computer controlled cutting head travels across the sheet, and as the ‘eye’ routes along the cut-path, it’s as accurate with the hundredth board as it was with the first.

The main benefit of the flatbed cutter is in its unparalleled precision. The substrate being trimmed never moves”

“It is also incredibly quick. If you’re always trimming similarly sized panels out by hand using something like a bench cutter or cutter bar, having a flatbed cutter will greatly increase your throughput. Its ease of use once set-up makes any cutting task a much more efficient and effective process.”

The master

Another thought that would enter a sign-maker’s head when choosing to spend money is: what other benefits will it offer me? Can I extend my services? Reader also says that a flatbed vinyl cutter can be used for other products, and even offer finishes that you might not typically think about.

“A flatbed vinyl cutter is a master of many applications,” explains Reader. “Available for each one is a wide variety of tools dedicated to time-saving and making production simpler. These machines can not only cut the vinyl letters for vans and signs, but they can also crease and score card, cut perforations, half cut and die-cut their way through a varied selection of media types and thicknesses.”

Reader concludes: “Summing up, from prototyping production panels to creating contour cut signage and displays, a flatbed vinyl cutter makes substrate or vinyl production fast, simple, consistent and reliable.”

One of the manufacturers that Granthams is a supplier for is Graphtec GB. Tom Kneale, a director of the company that was recently appointed to the board and taking over many responsibilities held by his father, managing director Phil Kneale, discusses the capabilities of the FCX4000 and FCX2000 series.

Tom Kneale was recently appointed to the Graphtec GB board of directors

He explains: “Flatbed vinyl cutting solutions from Graphtec GB include the latest FCX2000 and the small-format FCX4000 series of cutter/plotters.

(Above & below) Granthams is a supplier of a number of manufacturers, including Summa and Graphtec GB

Both machines share common as well as individual design characteristics, including Graphtec’s proprietary ARMS (Advanced Registration Mark Sensing) system for optimum plotting and cutting accuracy and Graphtec’s own-brand Pro Studio, Pro Studio Plus and optional Cutting Master 4 design and production software programs.”

Hold it together

Kneale continues to explain that the FCX2000 is available in three sizes, and a number of other features that aid with holding the vinyl in place – something that Reader also recognises as important when it comes to end quality. He says: “The FCX2000 is available in a choice of three sizes (the 60, 120 and 180). The machine offers respective processing areas of 610 x 920, 1,200 x 920 and 1,800 x 920mm, a cutting speed of 400mm/sec and a cutting force of 500gf up to a maximum 1kgf.

The FCX4000 is a smaller-format cutter from Graphtec

“The FCX2000 also offers the choice of either vacuum bed or electrostatic material hold-down functions, with the former better suited to the handling of heavier and thicker materials and the latter to lighter-weight media.”

Obviously, not all jobs are simple, and the FCX4000 is there to handle more difficult jobs that involve cutting.

Kneale also says that the 4000 is available in two sizes, compared to the 2000’s three options. “The FCX4000 is particularly suited to the handling of more difficult to cut media and for the post-processing of print-on-demand applications,” comments Kneale. “It is available in a choice of two sizes (the 50ES and 60ES) and provides respective cutting areas of 660 x 488 and 976 x 660mm. The machine has a maximum cutting speed of 750mm per second, a cutting force of 600gf and incorporates the electrostatic material hold-down facility.”

Kneale adds: “Both the FCX2000 and FCX4000 flatbed cutters are supported with a wide range of cutting tools and accessories to accommodate different material processing requirements. They are also fully compliant with all relevant CE safety and performance standards.”

The vinyl cutters highlighted here are available from both Graphtec and Granthams, and Reader concludes: “If you’ve been looking for the next step up from the roll-fed CAD plotter, one of these machines might just be the route to go.”

Many sign-makers may be scratching their heads as to why they should invest in a flatbed vinyl cutter if they are not in use all of the time. However, with the increased productivity and accuracy, it would allow those, who do not already, to offer services such as car wrapping – an in-demand marketing tool.

Your text here...