Before automated machines came in that incorporated technology such as lasers, cutting had to be done by hand

Vinyl cutters have come a long way from the time when cutting by hand, or with a manually operated machine, was the order of the day. With print formats becoming ever wider, and more sophisticated and intricate individual images to be cut out, CNC machines have come into their own and development of flatbed equipment in particular has gathered increasing momentum. Indeed, when Signlink covered this technology sector last year we focused exclusively on roll-fed vinyl cutters, a staple of the industry since the 1990s, but technology buying trends means that an evaluation of flatbed systems is also now important. Indeed, if you have the investment budget it would seem sensible to invest in a system that will allow you to both cut vinyl and a range of much thicker substrates.

From small beginnings

Key products in the Graphtec GB range of vinyl cutters include the entry-level CE6000 series, supplied with a two-year warranty and the flagship FC8600 series for higher-volume processing requirements. A major new addition to the Graphtec GB portfolio, the i-Mark automatic digital die cutter is based on the Graphtec CE6000-40 machine and dedicated i-Mark hardware and software. It can be used for high-speed die-cutting involving, for example, digital prints and short-run label and packaging productions.

The entry-level CE6000 series is a key product in the Graphtec GB range of vinyl cutters and comes with a two-year performance warranty

“As a key part of the sign maker’s armoury, vinyl cutters enable companies to engage with new markets as diverse as the print wear and promotional products, packaging design, labelling and digital printing sectors whilst helping close the gap between traditional sign making and these sectors,” observes Graphtec GB director, Phil Kneale.

He explains: “There are now many sign and graphics companies, invariably two- and three-person operations, moving conspicuously into, for example, the potentially lucrative print wear and promotional products sector on the basis that 90 per cent of the equipment installed for core manufacturing activities can now be adapted, with little or no additional investment, to create new market opportunities and introduce a vital new revenue stream to fuel business growth and commensurate profitability.”

One for all

Recent developments in flatbed cutters has seen the rise in multiple function machines that are capable of cutting not only vinyl but a variety of other materials, meeting the demands of sign and display manufacturers who serve an increasingly wide range of markets.

“The modern busy sign maker has available on the market a wide array of vinyl cutting and plotting equipment to choose from,” comments Leopold director, Steve Leopold, adding: “However, the introduction and wide use of CNC flatbed cutters within the sign industry now gives the small to medium size sign shop the opportunity to buy a single piece of machinery that can be used for many sign applications, including routing solid substrates as well as vinyl cutting.”

A recent addition to Leopold’s portfolio is the new Colex SharpCut range of low cost general purpose CNC flatbed cutters ranging from 1.6m to 3.2m, that are capable of finishing media such as paper and vinyl, through to 25mm thick aluminium.

The new Colex SharpCut range of low cost general purpose CNC flatbed cutters from Leopold are capable of finishing media such as paper and vinyl, through to 25mm thick aluminium

“This means that the entry level sign fabricator needs to buy only one piece of equipment to cover a wide range of finishing, including vinyl mounted dibond and foamex,” Leopold emphasises.

One such company is Blue Gecko in Hallatrow near Bristol, which purchased a Colex SharpCut just over a year ago.

Stefan Canale, Blue Gecko’s operations director says: “The Colex SharpCut has transformed our business, achieving production goals and precision cutting never before possible.

The machine came complete with all the necessary tools and everything needed, including installation and online support, at a very reasonable price. The SharpCut’s solid construction and ease of operation also made the SharpCut an obvious choice for Blue Gecko”

“Without the Colex SharpCut Blue Gecko would not have been able to expand into other areas of the sign market and increase our turnover in the last year. The SharpCut is fast reliable and adaptable for all of our finishing needs and moreover didn’t break the bank when we purchased it,” adds Canale enthusiastically.

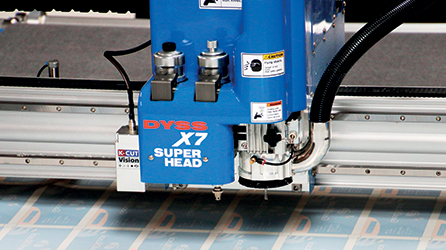

DYSS X5 and X7 Digital Cutters from AG/CAD are equipped as standard with a two-tool head, which can be loaded with a kiss cut as well as a heavy duty knife tool, enabling precise, consistent kiss-cutting and through-cutting of any roll media.

DYSS X5 and X7 digital cutters from AG/CAD are equipped as standard with a two-tool head, which can be loaded with a kiss cut as well as a heavy duty knife tool

DYSS cutters are true flatbeds and have ‘tangential’ tools that use motors to control the precise direction of the blade.

DYSS cutters from AG/CAD are true flatbeds and have ‘tangential’ tools that use motors to control the precise direction of the blade, resulting in precise, clean-cut corners

“This results in the highest quality corners,” emphasises AG/CAD sales director, Andrew Boulton, adding: “Many standard vinyl cutters are upright and use ‘drag knife’ tools, which can mean sharp corners are often not perfect. Upright cutters are also less suitable for through cutting as the cut pieces will fall out and have to be ‘tagged’ in place, meaning additional labour for each job to remove these pieces.”

Boulton notes: “DYSS cutters are future-proof and allow any print business processing vinyl to grow into other areas. With ‘plug and play’ tooling available to retro fit when required, it is simple and quick to expand into processing heavier graphic media such as rigid PVC, HIP, magnet, Correx, solid display board, honeycomb, corrugated.”

A high specification router option on the X7 allows an even more comprehensive range of materials to be handled including Dibond ACM, Acrylic, PETG, and Stadur.

“The final piece in the jigsaw is always the machine control software,” continues Boulton, adding: “DYSS machines come with specialised Kasemake software, which out of the box has everything required to read files generated by most printer RIPs or graphic software, identify printed registration marks to align cutting perfectly to print, split longer-than-bed jobs up into bed-size sections, etc.

The final piece in the jigsaw is always the machine control software”

“Optionally, this software also allows access to the expert knowledge built into literally hundreds of user resizable design templates, opening up new and lucrative markets. Clever functionality even allows 3D virtual proofing and presentation of designs and whole environments, adding further value and assisting with sales proposals to customers.”

“DYSS X5 and X7 Digital Cutters are the ultimate machines for 24/7 continuous processing of vinyl, banner mesh, paper and other roll media of any length. And the combination of DYSS machines and KASEMAKE software ensures that the sky is the limit for any print or signage business,” concludes Boulton.

Scaling up

With over 50 years of experience in the design and manufacture of cutting solutions, Essex based Blackman and White is the only UK manufacturer of large-format cutters for the sign and display industry. At Sign and Digital UK 2016, the company showcased its latest image recognition software, which uses the latest generation of camera technology, and new conveyor belt technology on its flagship Versa Tech cutter.

The Versa Tech incorporates laser, knife, and router tooling, allowing a wide spectrum of materials to be finished using a single machine, as well as savings on the floor space that would be required for three machines.

“Our Versa Tech cutting platform is proven as a very reliable solution for cutting vinyl,” says managing director, Alex White, adding: “The advantage of using a flat bed or conveyorised cutting solution is that you are able to get a much more stable platform to cut from.

Complete CNC Solutions is another very key supplier of cutting equipment to the UK sign industry. It used this year’s Sign and Digital UK exhibition to provide visitors with free consultancy and tooling samples on the biggest stand it has ever taken at the show. The company used its space to demonstrate a fully-featured Tekcel production router, as well as the new 2016 specified Unico TT and a new Unico CNC—both of were making their UK debuts.

Complete CNC says the Unico TT ‘outperforms many routing systems, providing powerful routing, knife cutting, creasing, engraving, and incising tools’.

The Protek Unico TT from Complete CNC Solutions allows you to cut vinyl like a hot knife through butter, but also gives you the ability to process a massive range of heavy-duty materials

At the time of its launch, the managing director of Complete CNC Solutions, Julian Sage said: “Most lightweight print finishing systems generate an appetite for routed output. That’s like making an appointment they can’t keep.

The Unico TT moves forward with your business and moves your business forward. There’s not a serious routing production or knife-cutting task it can’t rise above. It really does do it all.”

Sage explains that the Unico CNC has been designed to deal with high volume workloads, is available in a range of sizes, and comes with accessories such as a flatness sensor, camera, and knives. He also claims that the quality of the output the Unico CNC produces ‘positions it in a class of its own’.

Choosing wisely

When reviewing the wide range of options available to sign-makers, whether at entry-level or larger companies looking to further evolve their offering, there are, as always, some key points to consider.

Graphtec GB’s Kneale offers a word of caution: “For entry-level sign and graphics producers, in particular, the important consideration is to avoid the temptation to invest in cheap but patently inferior vinyl cutters (frequently those imported from countries such as China) and always to opt for slightly more expensive but infinitely more reliable branded alternatives. Failure to do so will invariably lead to expensive repair, maintenance and downtime costs and ultimately customer dissatisfaction and a loss of business.”

Graphtec GB’s i-Mark automatic digital die cutter, a major new addition to the company’s portfolio, can be used for high-speed die-cutting involving, for example, digital prints and short-run label and packaging productions

“Clearly our technology is not well suited for the start-up company just beginning in the market place and lower cost roll-to-roll alternatives are the right starting place,” observes White, adding: “However, as sign companies grow quickly the limitations of these machines become apparent and the ability to cut other materials such as reflective films for road signs becomes a clear advantage. And this is where the high speed and capability of the range of Blackman & White machines lend themselves well to the future growth potential of the sign company.”

O Factoid: In 1988, Roland DG launched the world’s first dual-purpose vinyl cutter and pen plotter. O

Looking at the wide variety of options on the market, there is clearly a vinyl cutter that lends itself to every stage of growth and diversification in the development of a sign-making business. However, with careful choice and planning, you can purchase a machine that not only meets your current requirements but has the capability to help you address future needs and market demands, without the necessity of installing additional equipment.

Your text here...