Zünd says the Automatic Router bit Changer feature on its G3 range of machines helps make milling, polishing, and engraving more cost-effective

When customers ask how you were able to achieve the appearance of a finished product, their own minds are already thinking about wide-format printers and their many different features. However, while this sort of technology may give an application its visual appeal, kit such as flatbed knife-cutters are an obviously vital part of the production process.

As with all other areas of production, investment in quality kit for this process is critical; cutting costs here may save you money in the short-term, but could end up costing you a lot more in the long run. After all, if the piece does not shape up to a customer’s requirement, then there is little chance of them returning. But what options are available to sign-makers and wide-format print companies? How can they identify the quality solution that they need and what can they do to ensure it will adhere to their high standards?

Considering long-term impact

Zünd Plotting Systems is one company that is not only respected within the UK market, but also across the global industry. Ian Guest, sales demonstrator at the firm’s UK arm, says cutting corners and opting for cheaper equipment can cost companies in more than just financial terms.

“What can be a short-term financial saving can be a long-term headache financially, but also in terms of productivity and quality of finished product,” he says, adding: “Zund machines are all Swiss-built to order, and offer unrivalled durability and quality.

What can be a short-term financial saving can be a long-term headache financially, but also in terms of productivity and quality of finished product”

“Those that purchase quality kit will be able to offer a quality product to their customers. They can also expect better productivity and higher reliability, therefore not interrupting production with costly breakdowns.”

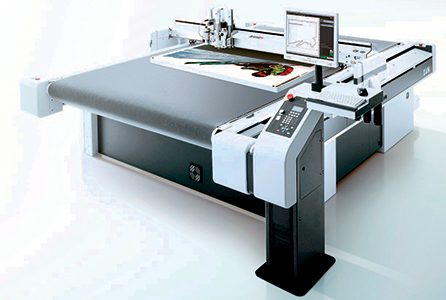

Guest goes on to outline Zünd’s flatbed knife-cutters offering in this sector, which comprises two ranges of machine—the G3 and S3.

Zünd offers two ranges of flatbed knife-cutters: G3 for larger-format work and the S3 smaller-format machine

“The G3 is a larger-format machine, aimed at rigid boards and roll medias up to 3.2m wide, and up to 50mm thick,” he says, adding: “Capable of cutting a wide variety of materials including acrylic, expanded PVC, ACM, MDF plywood, and aluminium, combined with the G3’s Automatic Router bit Changer, makes signage quick and easy to produce, whilst maintaining the highest quality.

“Roll medias such as banner, vinyl, textiles and many more can also be produced with the G3’s comprehensive selection of material handling systems.

“The S3 is a smaller-format machine, aimed at those looking to process more rolls than boards but can still be specified with a 1Kw Router module to process the same rigid boards as the G3, up to 25mm thick.”

Guest also reveals that Zünd used this year’s Drupa show to launch a new machine he believes will ‘redefine productivity’. He adds: “Recent developments already released include the G3’s Automatic Router bit Changer, as well as a new perforating tool for corrugated board, carton, vinyls and polypropylene, and a robot arm for stacking cut parts.”

Invest in flexibility

Known to many across the industry for its flatbed inkjet printing solutions, it may come as a surprise to some that Agfa also offers cutting solutions. Steve Collins, marketing and channel manager for Agfa UK and Ireland, says while some less expensive products can offer solutions to users, its processes may be limited, therefore decreasing the amount and type of work you can take on.

Collins expands: “It all comes down to versatility; less expensive products will limit the amount of substrates supported, thus reducing the capabilities of the applications.

“The robustness of the machinery is crucial to the level of quality achieved from the routing tools. Better-built products can also cut and mill at higher speeds giving a quicker return on investment.”

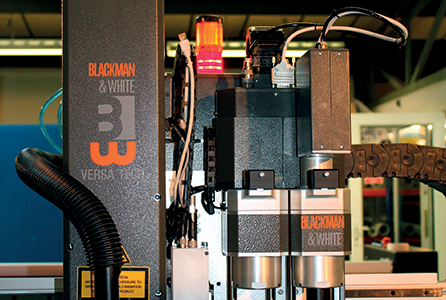

(Above & below) Steve Collins, marketing and channel manager for Agfa UK and Ireland, says that the robustness of a machine is vital to the level of quality achieved from routing tools

With these considerations in mind, Collins picks out some of the solutions and products on offer from Agfa. These include the Acorta range of cutters that are fully integrated with Afga’s popular Asanti workflow software, which Collins says allows for seamless integration between the print and finishing processes.

New to this portfolio is the Acorta 3120 HD, which Collins bills as a ‘high-end’ addition to existing products in the range. Collins adds: “The Acorta 3120 HD is targeted at very thick or dense materials, completing the Acorta family of cutting plotters.” The machine had its first worldwide showing at Drupa and also has some very clever tricks up its sleeve such as a mobile overhead gantry that carries a high resolution projector that is tied into Agfa’s software. It means you can project the cutting paths directly onto the board to reduce material wastage and improve set-up efficiency.

Spend wisely

Also well-stocked in this sector is Blackman and White, which counts the likes of the print-focused Versa Tech amongst its product range. Alex White, managing director of the wide- and large-format cutter manufacturer, says that the initial investment by companies is critical in the long run.

Available from Blackman and White, the Versa Tech knife-cutter has been designed for those in the print sector

White expands: “A new cutting table should be seen as an investment for at least ten years, with many still running 20 years on, so you need to know that the manufacturer will be there to offer the same level of support throughout its lifespan.

“Buying a machine from overseas based on its lower manufacturing costs can be a big gamble, as not only are you relying on technical support sometimes delivered from a distance, distributors may also change direction over time and import from a different supplier, leaving customers with no contacts when they desperately need help.

“With a well-established, UK-based company like ours you can at least be sure that we will be there, on the doorstep, offering specialist support for the lifetime of the product, and that our machines meet all the necessary health and safety regulations.”

White also picks up on the importance of software and the production flow when it comes to investment in technologies, explaining: “The integration of a machine into a large workflow solution is critical to future success.

The ease of operation and clear error messages allow for fast and efficient operation, and ongoing software developments from the suppliers of the cutting machine purchased should make the machines faster and easier to use over time.”

With this in mind, White speaks in more detail about the Versa Tech, specifically developed for the print industry and features a high-powered router alongside the knife tooling. Blackman and White also offers the lower cost alternative of the Genesis cutter, with the option of a fixed or conveyor bed, with the latter for applications requiring only knife tooling.

White adds: “New technology is essential to improve automation and the goal in the industry is to move to unattended cutting.”

Establishing a presence

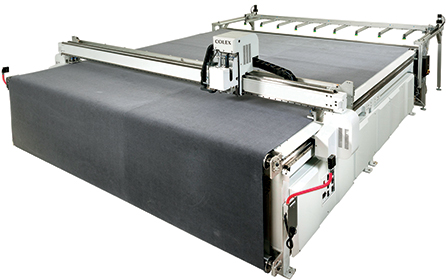

Although a relatively new brand in the European market, Colex has established itself in the US, with more than 280 installations to its name. With representation in the UK through a distribution agreement with Leopold Professional Imaging, the company is now well placed to support companies in our market.

Colex is a new name in the European market, but has completed more than 280 installations in the US

Steve Leopold, managing director of Leopold Professional Imaging, says: “Colex has designed and built a range of general purpose CNC machines at realistic prices for the print and sign making industry and come in at £55,000 for the 3 x 1.6m fixed bed table.

“The approach that Colex has taken is to offer a CNC machine that is capable of handling all the finishing tasks demanded by the modern sign-maker. The SharpCut machine will handle materials from kiss cutting vinyl to 25mm thick aluminium and anything in between.

“The Sharpcut comes complete ready to go, with workstation and software, a full range of tools for knife cutting, V cutting, kiss cutting, fabric cutting, as well as a 3hp router with laser positioning for dibond, acrylic, wood and other solid substrates.”

Launched at this year’s ISA and available in the UK from Leopold Professional Imaging, the SharpCut 3.2 x 3.2m is a wide-format flatbed cutter with optional conveyor and board loader

Leopold recognises a potential issue with investing in equipment from a foreign brand, but dismisses any concerns over Colex kit, commenting: “If the performance and capability are similar, then I don’t think there is a danger, providing the flatbed cutter meets your sign shop’s requirements and performs as required, then it’s the right machine at the right price for the job.”

Leopold is also keen to highlight the range of Fotoba wide format X-Y cutters that his firm supplies. The machines are designed for high speed finishing of flexible medias up to 1mm thick, and, for square cut finishing of flexible media. The Fotoba cuts at a linear speed of 18m/min, which he says is three times faster than any other flatbed CNC cutter when finishing rolls.

He adds: “This is why Leopold offer a package of the Colex SharpCut together with the Fotoba XLD170 for £80,000. This combination of equipment covers the full gamut of finishing for roll and solid substrates for a busy print and sign producer.”

O Factoid: Although a newcomer to the European market, Colex has over 280 installations to its name in its native US. O

While there are plenty of solutions available on the market, and sign-makers and wide-format printers seemingly have their pick of products, one theme running throughout this piece is that if you want quality, prepare to invest. Yes, cheaper machines may offer financial savings in the short-term, but this also comes with less flexibility when it comes to taking on work. The question you have to ask is are you willing to turn away work if it means, initially, cheaper investment?

Your text here...