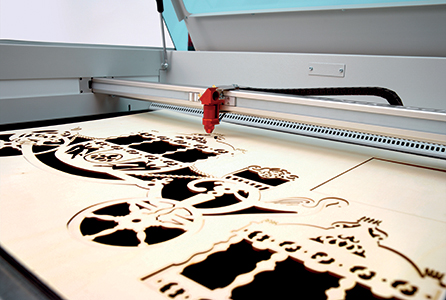

Lasers are used to slice through anything from stainless steel to paper and everything in between. Pictured: Wood being cut by a Trotec SP1500

Taking in the trade stands at Sign and Digital UK at the NEC, it is easy to feel that laser cutters are a new and exciting development in the last couple of years. Compared to some technological advances in the sign industry, they are the ‘new kids on the block’, but in the popular imagination, laser cutters are old hat. Both Jules Verne and HG Wells predicted their use in their science fiction novels of the 19th century, while Arthur C Clarke described a particle beam device in his 1955 novel Earthlight.

Star Trek, Lost In Space, and Star Wars have all taken on the idea of lasers following their invention in 1965 when a laser cutter was used to drill holes in diamond dies. Throughout the 1970s and 1980s, firms in the aerospace industry pioneered their use to cut materials such as titanium, while CO2 lasers—where CO2 is used as an assist gas in the process—were developed to cut non-metals including textiles and wood. When oxygen is used as the assist gas, a slightly burnt edge can be left to cut while nitrogen is used in order to leave a cleaner finish.

Choosing which laser

The actual laser head is where the action takes place. A beam of light is emitted from the laser tube and is reflected by tiny mirrors into the laser head where a lens focuses the beam onto the material surface for cutting or engraving. To guide the head, digital computer technology allows for the shape of the area to be cut or engraved to be scanned and programmed into the machine, which then passes over the material quickly cutting away the exact shape required. Lasers can cut or engrave stainless steel, mild steel, acrylics, and softer materials like textiles, leather and paper.

Cutting through Perspex leaving a clean finish with crisp edges has been a triumph for laser cutting, with the ability to cut the same shapes over and over again on a mass production scale

Craig Brown of Signs Express gave his view on the types of laser cutters available: “Fundamentally, every model has different strengths and weaknesses and these really depend on what you want to cut or engrave. When buying a laser cutter you really need to do your research; there are two main choices in cutters, CO2 lasers or fibre lasers depending on the types of materials you are looking to cut/engrave. CO2 laser cutters are designed to be used on wood, acrylic, glass, paper, leather, and stone, however, if you are looking to engrave harder materials like metals and plastics, fibre laser cutters have a laser beam that is 100 times more intense than CO2 lasers and are much more suited for use with more durable materials.”

Entry level

With this sage advice in mind, it is perhaps helpful to set out the current perception of what laser cutting technology can be applied to by veteran industry firm, Cut Laser Cut, which explains its take on this technology with this statement: “Laser cutting is a precise method of cutting a design from a given material using a CAD file to guide it. There are three main types of lasers used in the industry: CO2 lasers Nd and Nd-YAG.—we use CO2 machines. This involves firing a laser which cuts by melting, burning or vaporizing your material. You can achieve a really fine level of cutting detail with a wide variety of materials. Bare in mind that CO2 lasers can’t cut metals and hard materials, they can however engrave them.”

O Factoid: Lasers can cut or engrave stainless steel, mild steel, acrylics, and softer materials like textiles, leather, and paper. O

Another firm is CTR Lasers, based in Northamptonshire, which manufacturers and supplies CNC laser cutting, engraving, and marking machines. Its range of laser cutters are used in education, manufacturing, and by sign-makers with their TMX starting with entry level smaller machines but including their TMX15 model that has a cutting area of 1,200 x 900mm.

CTR’s TMX65 water cooled laser cutter has a work area of 650 x 420mm while its larger cousin has a working surface of 1500 x 1300mm

Using the laser cutters is now a straightforward process. First, the artwork is designed and submitted as normal in the form of a pdf or other file type, and the computer prepares it for cutting just as you would for printing. Adjustments can be made, measurements altered, and the layout approved to fit into the area of cutting surface.

The machine reads vector strokes of hairline thickness in red. Then the chosen material is laid onto the flat bed of the cutting machine ready for cutting as the machine is adjusted for power, speed, and frequency to suit the chosen material. The sheet area can go up to 2,400 x 1,200mm or higher on some cutters. After that, the machine will then follow the path of the drawing zipping its way round the material, following the lines automatically. Underneath the material, a protective backing is laid which is peeled away once the job is done.

Simplicity to complex cutting

The types of work the cutters produce are the traditional ones of signs, logos, typography, and imagery produced by more labour intensive methods. What laser cutters do is to have the ability to produce the chosen shapes accurately, with speed over and over again. And those are the obvious USPs of the technology. They are used to create stand alone signs in two dimensions, or to create layers of materials to be assembled for a more complex design such as sports clothing.

Intricate cutting is possible even on wood, allowing for extremely detailed shapes to be created

The down side is laser cutters do not come cheap, with prices for an industrial standard laser cutter in the £20,000 mark and rising or falling depending on the size and model. Engravers can be picked up for much less with second hand ones in the hundreds of pounds mark. The one tip most in the trade will give you is to shop around, then go and see working models in sign firms similar to yours and ask for their feedback. Once you have chosen your favoured machine approach the distributor if you are looking for a new one and ask if they will give you a discount at a trade show like Sign and Digital UK. There the negotiations start, but one thing all exhibitors like to trumpet at an exhibition is how many machines they have sold on day one—so it is worth explaining you would like to seal the deal at the show and you may find them more willing to give a little on price.

Some of those involved in the technology exhibiting at the NEC in April at Sign and Digital UK are Trotec Laser, HPC Laser, and Grafityp. If you are looking at investing in the machines, then it is good advice to talk to some of those on the trade stands and also fellow sign-makers talking to the sales and marketing people at the event.

Trotec’s Speedy range of cutters means a large amount of work can be carried out with swiftness and accuracy

Trotec has a range of laser engravers and laser cutters including their SP series of CO2 machines with the SP3000 with a work area of 87 x 126. HPC Laser, which is the UK and European distributor of Laserscript CO2 laser cutting machines and laser engraving machines. Grafityp will feature its LaserPro X series equipped with a CO2 laser which it says offers a “reliable source of 80W and 100W of power for mass production requirements.”

The Trotec SP series has proved to be popular with this emerging sector, with the 1500 leading the way for many sign-makers in laser technology

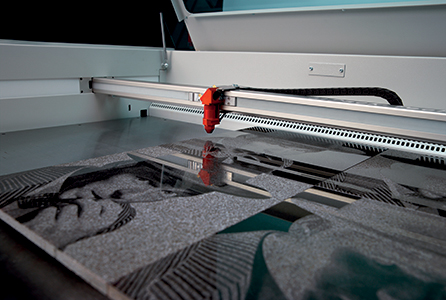

The benefits of laser cutters when it comes to cutting textiles are the absence of problems of shrinkage and frayed textiles as well as potential mistakes in measuring. Laser cutters eliminate the operator’s need to calculate for any shrink, stretch, or deformation of the fabric during the printing process. The exact size of the cut path is projected down over the printed image, the operator has the option to reposition the outline before the low wattage laser cuts and seals the textile to the exact size without burning the edges. Controlled by a computer, the system has the benefit of being precise.

Laser cutters eliminate the operator’s need to calculate for any shrink, stretch, or deformation of the fabric during the printing process”

So why buy a laser cutter? Everything they do can be achieved just as well with existing techniques. Hand engraving, routers, and cutters can all achieve the same effects. And as for cutting textiles, what is wrong with a pair of scissors and a steady hand? The main motivation is speed, accuracy, and quantity. Trotec and other manufacturers stress the profitability angle explaining that as long as there is a full order book, a laser cutter will quickly pay for itself with a return on investment that is achieved within a few months.

This Perspex image with fine detail shows how flexibility is one of the hallmarks of laser cutters

Of course, computers can have problems and they are only as good as the person who is using them but it seems laser cutting and engraving is here to stay, and is set to become more sophisticated. As their ability to cut complex three-dimensional shapes and to engrave on larger and larger surfaces, then the potential of this technology is only just being discovered. First conceived by science fiction writers in the days of Queen Victoria, the true century of discovery is yet to come.

Your text here...